Steam turbine generating system with indirect regulation on regenerative side and primary frequency regulating method

A power generation system and steam turbine technology, applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems of reducing steam working ability, unit shaft vibration, and increased unit heat consumption, so as to reduce heat consumption and reduce Effects of reducing heat consumption and economic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention are described in detail below:

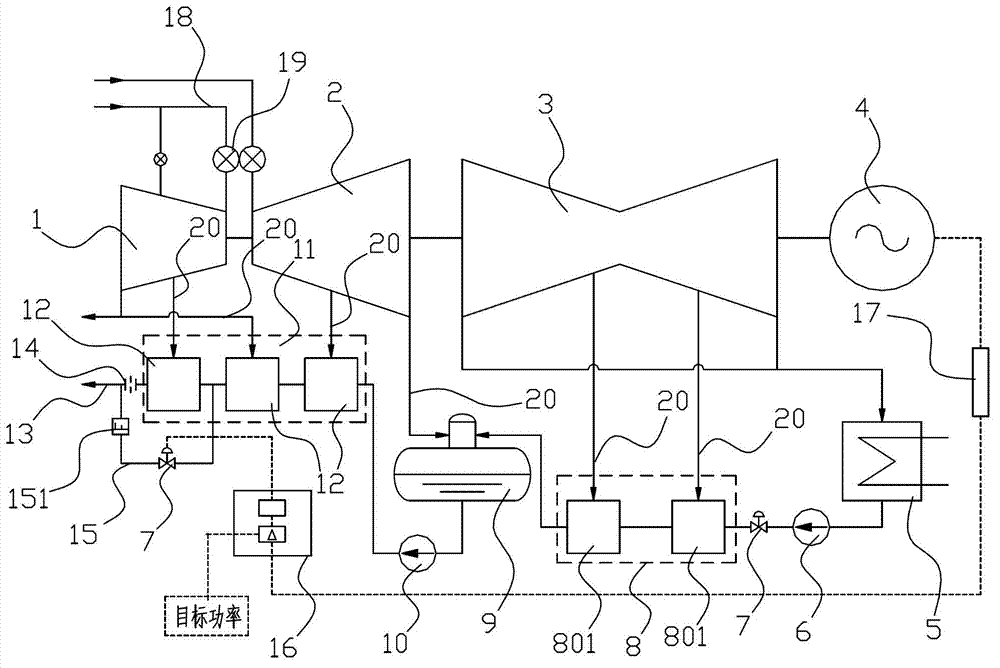

[0030] Such as figure 1 As shown, a steam turbine power generation system indirectly regulated on the heat recovery side includes a steam turbine, a condenser 5, a low-pressure heating system 8, a high-pressure heating system 11, and a generator 4 driven by a steam turbine, a steam turbine, a condenser 5, and a low-pressure heating system. The system 8 and the high-pressure heating system 11 are sequentially connected by pipelines, and the steam turbine and the high-pressure heating system 11 and the steam turbine and the low-pressure heating system 8 are respectively connected with extraction pipelines 20, and the high-pressure heating system 11 is connected in parallel with a bypass pipeline 15, and the bypass pipeline 15 is equipped with an automatic flow regulating device, which is electrically connected with the generator 4.

[0031] Wherein, the automatic flow regulating device includes a contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com