Multi-working-condition design method for guide vanes of axial flow pumps

A design method and technology of axial flow pumps, applied in the direction of components, pumps, pump elements, etc. of pumping devices for elastic fluids, to achieve the effects of improving operational reliability, widening range, and good response effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

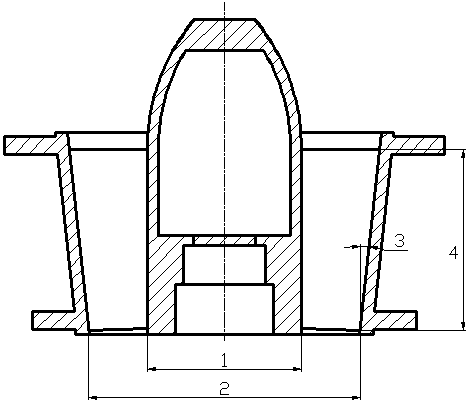

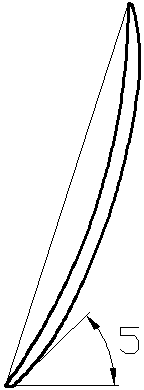

[0034] figure 1 and figure 2 Together determine the vane shape of this embodiment. The present invention adjusts the guide vane hub diameter through the following relations D h (1), guide vane inlet diameter D 3 (2), 1 / 2 guide vane divergence angle θ / 2(3), guide vane height h (4) and the installation angle of guide vane inlet of each flow surface α 3k (5), so that the performance of the axial flow pump of this embodiment meets the flow rate of the optimal efficiency working condition Q BEP , the head of the optimal efficiency condition H BEP , No. i The flow rate of the operating point Q i , No. i Head of operating point H i , impeller speed n requirements.

[0035]

[0036]

[0037]

[0038]

[0039]

[0040]

[0041]

[0042]

[0043] In the formula: Q BEP ——the flow rate at the optimal efficiency working condition point, cubic meters per second;

[0044] H BEP ——The head of the optimal efficiency working point, m;

[0045]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com