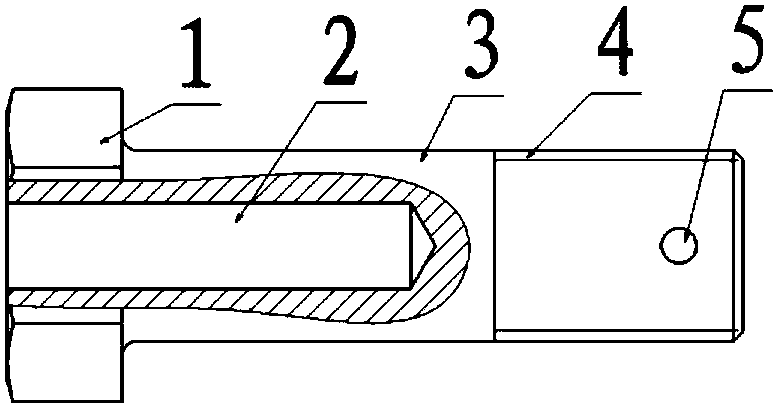

Safety bolt with blind hole

A technology of safety bolts and blind holes, which is applied in the direction of bolts, screws, nuts, etc., can solve the problems of reducing bearing capacity, affecting stress distribution, stress concentration, etc., and achieve the effect of increasing parts and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention is described in further detail below by way of specific embodiments:

[0008] The safety bolt of the present invention is applied in the emergency disconnection design of the inner flap of the ARJ21-700 aircraft. It is made of A286 solid solution aging stainless steel round bar. The outer diameter of the bolt is 19.6mm, the inner diameter of the blind hole is 8.6mm, and the depth of the blind hole is 58mm. Because the screw part of the bolt does not have a groove, the screw part of the safety bolt has a smooth profile surface; and the blind hole has a certain depth, not only the cross-section at the groove in the prior art is reduced, which increases the risk of fracture during emergency The parts that may be generated, thereby improving the reliability of emergency fracture. In addition, the shape of the safety bolt of the present invention is the same as that of ordinary bolts, and can be assembled in the form of ordinary bolt connections.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com