Unit module combined air valve

A unit module, air valve technology, applied in the direction of lift valve, valve detail, valve device, etc., can solve the problems of unfavorable production cost and use cost, inconvenient manufacturing, transportation, installation, reduction of effective ventilation area, etc., to achieve a simplified combined type The effect of air valve structure, compact structure and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

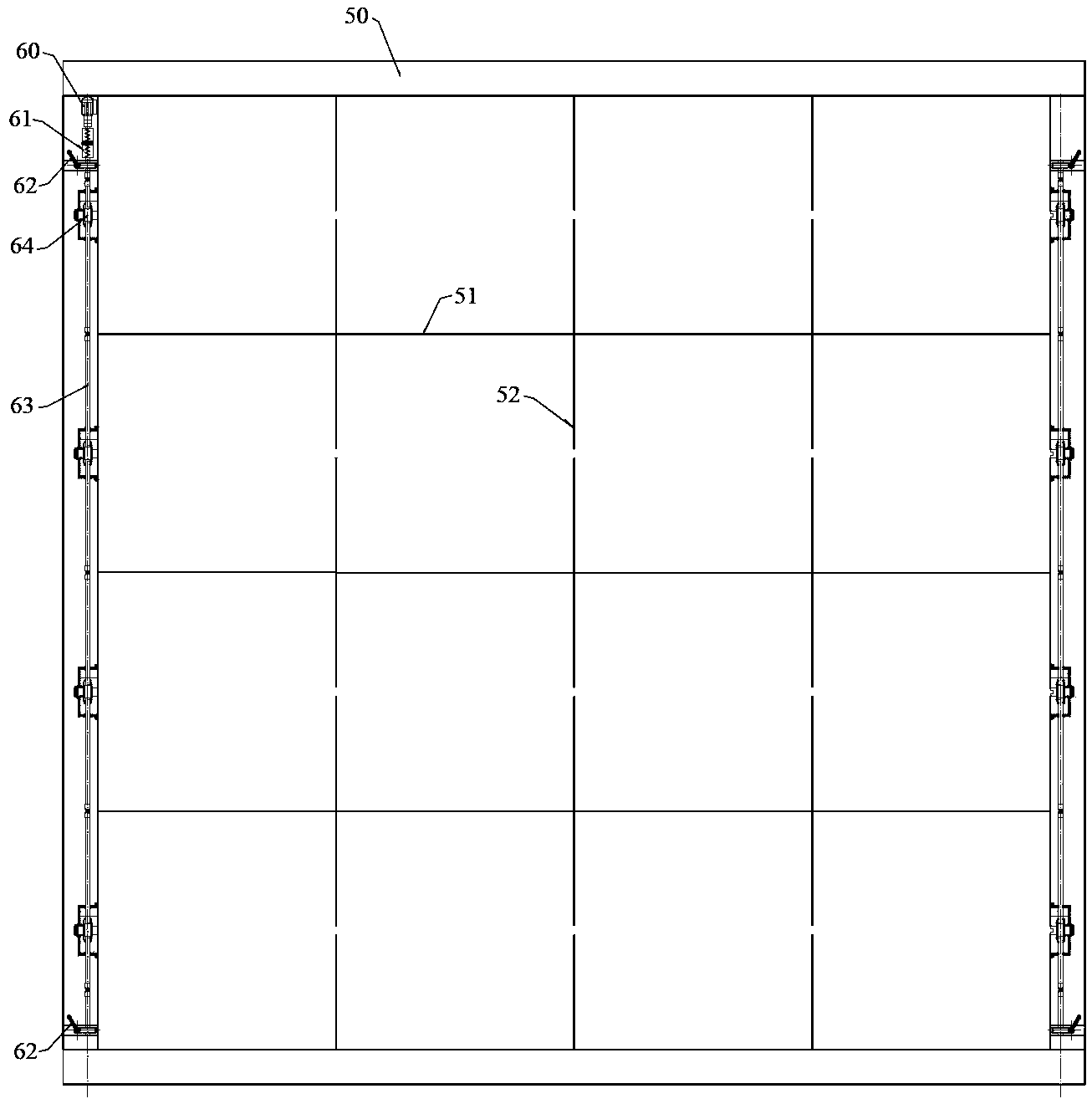

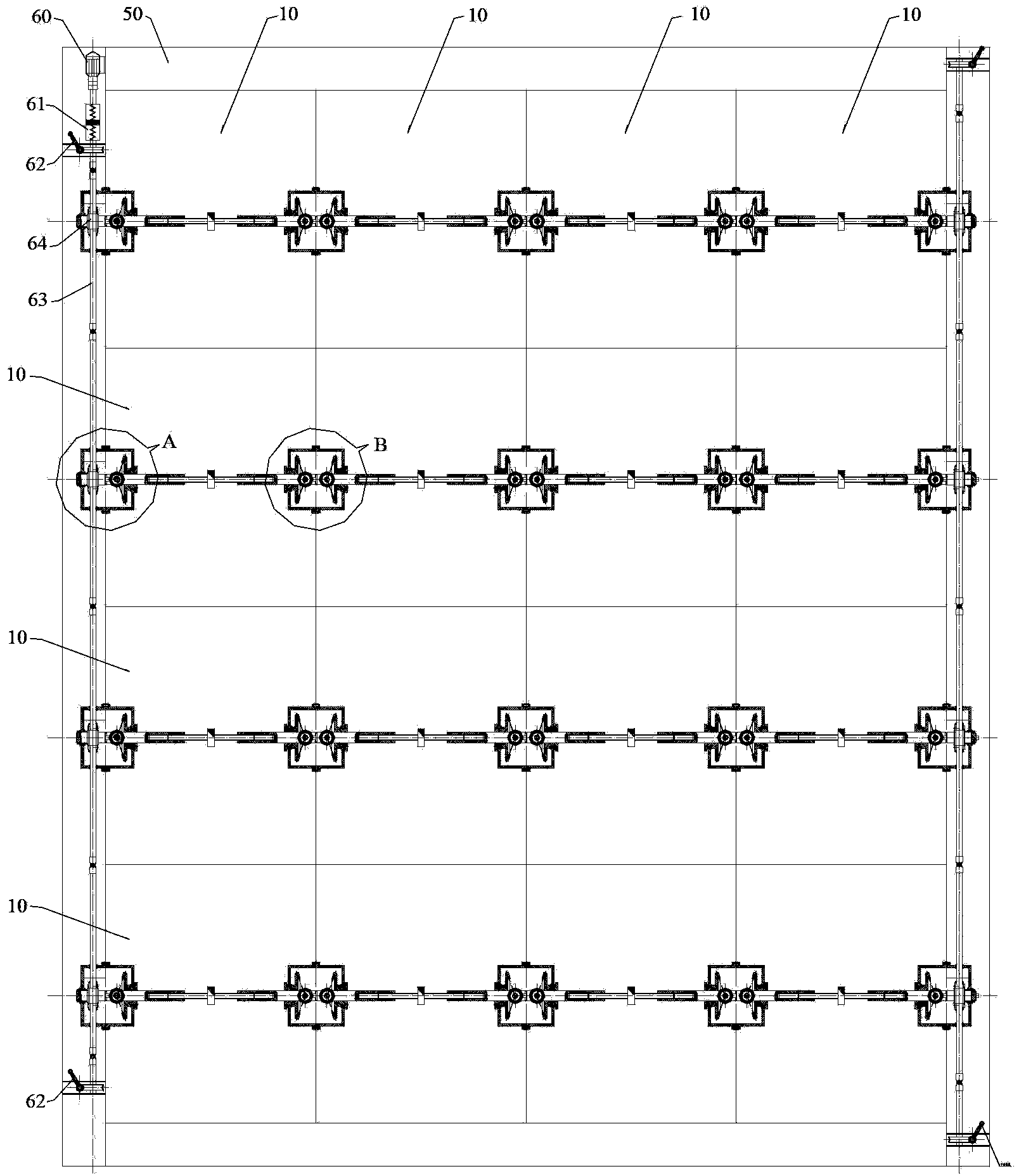

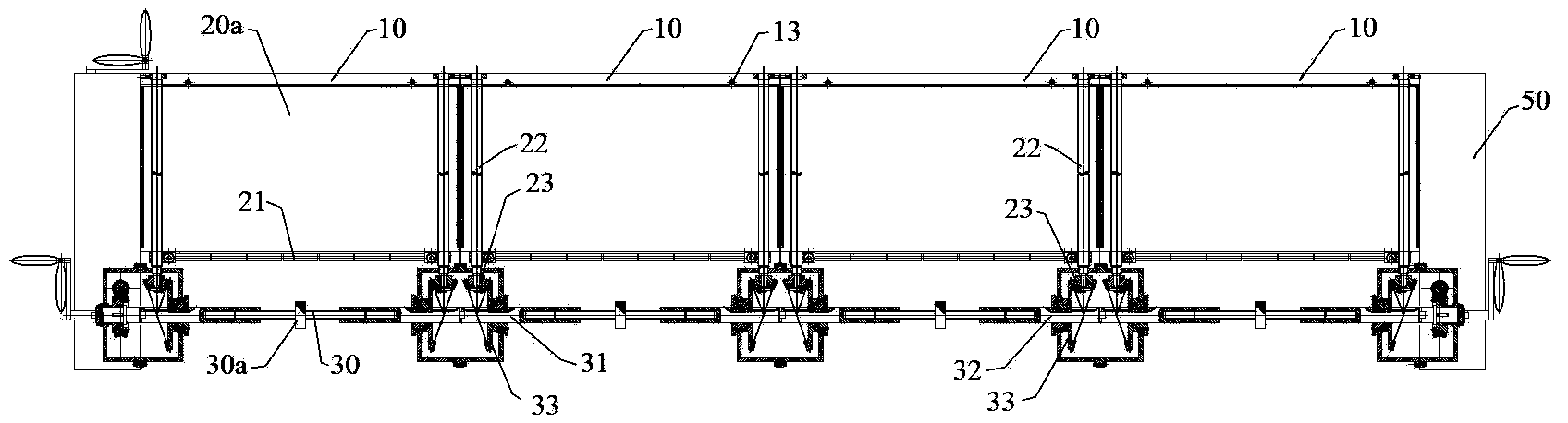

[0026] refer to figure 1 , figure 2 and Figure 8 , the unit module combination damper of the present invention comprises: integral frame 50, and the frame grid formed by parallel transverse plate 51, vertical plate 52 is fixedly arranged in it as the force-receiving structure; Unit module 10, is arranged on each frame grid In the rectangular grid, each unit module 10 has an internal transmission mechanism that drives its blades to open and close, and has a coupling structure 34 that drives and connects the internal transmission mechanisms of adjacent unit modules 10; the linkage device is arranged on the overall frame 50, An internal transmission mechanism for driving each row or row of unit modules.

[0027] The unit module combination damper of the present invention realizes modular combination, and each unit module 10 has an integrated internal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com