Inflating type pipeline connecting clamp hoop

A connection card, inflatable technology, applied in the direction of pipes/pipe joints/pipe fittings, stuffing seals with fluid pressure, passing components, etc., can solve the problem of inability to dynamically adjust the clamping force, affect the flow area, and rubber Problems such as cracking of rings can be avoided, achieving the effect of low installation requirements, wide adaptability, and reduced installation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

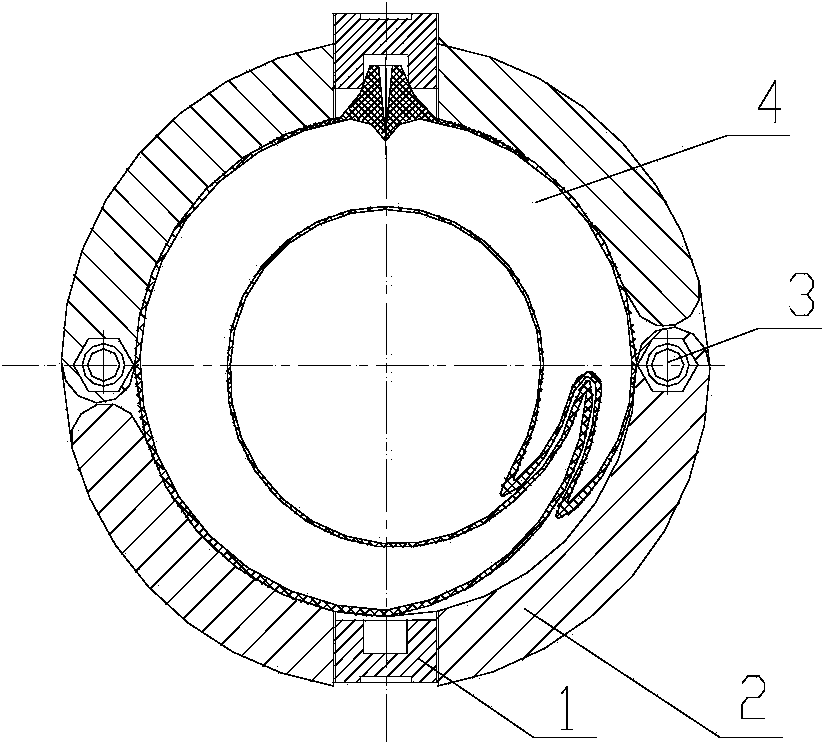

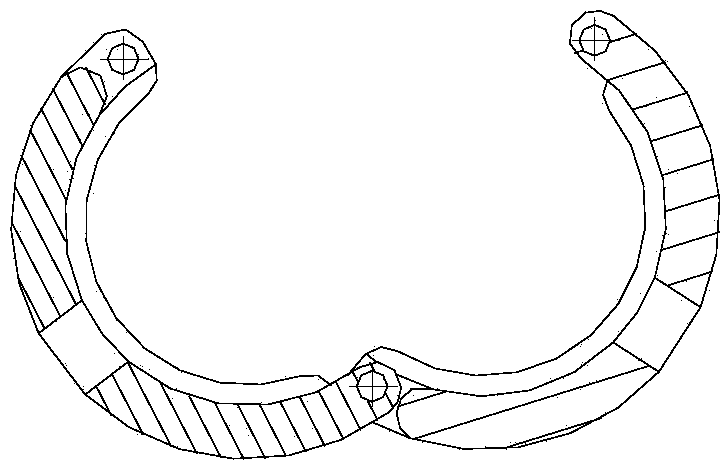

[0023] See attached figure 1 , an inflatable pipeline connection clamp, which includes: a plug 1, a clamp 2, a bolt 3 and an air bag 4;

[0024] The clamp 2 is two metal half rings, and the two metal half rings are connected by two bolts 3 to form a complete ring body, and the middle position of each metal half ring is provided with a radial threaded through hole;

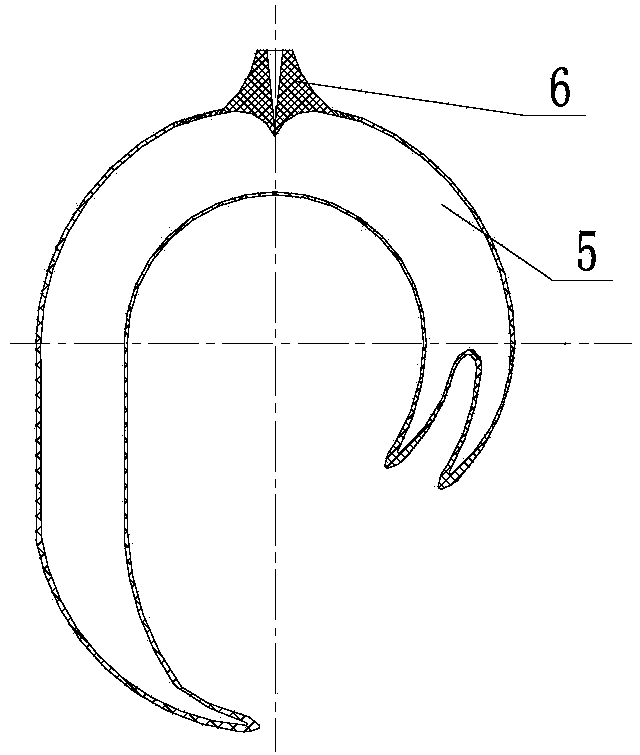

[0025] The airbag 4 includes: an airbag body 5 and an airbag inflation nozzle 6; the airbag body 5 is a strip structure, one end of which is pointed, and the other end is provided with a U-shaped gap. Located in the U-shaped notch at the other end; the airbag inflation nozzle 6 is arranged on the airbag body 5;

[0026] Under normal circumstances, the inside of the airbag 4 is filled with gas with a certain pressure, so that it can reach a full state, so that it can be conveniently placed in the installation groove of the inner wall of the metal half ring in the clamp 2; the airbag inflation nozzle 6 is aligned wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com