Device and method for detecting defects of loudspeaker net by ultrasonic waves

A detection device and ultrasonic technology, which are applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, can solve the problems of uncontrollable quality, lack of detection means, poor sound propagation effect, etc., and achieve the effect of simple and accurate detection by the device and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

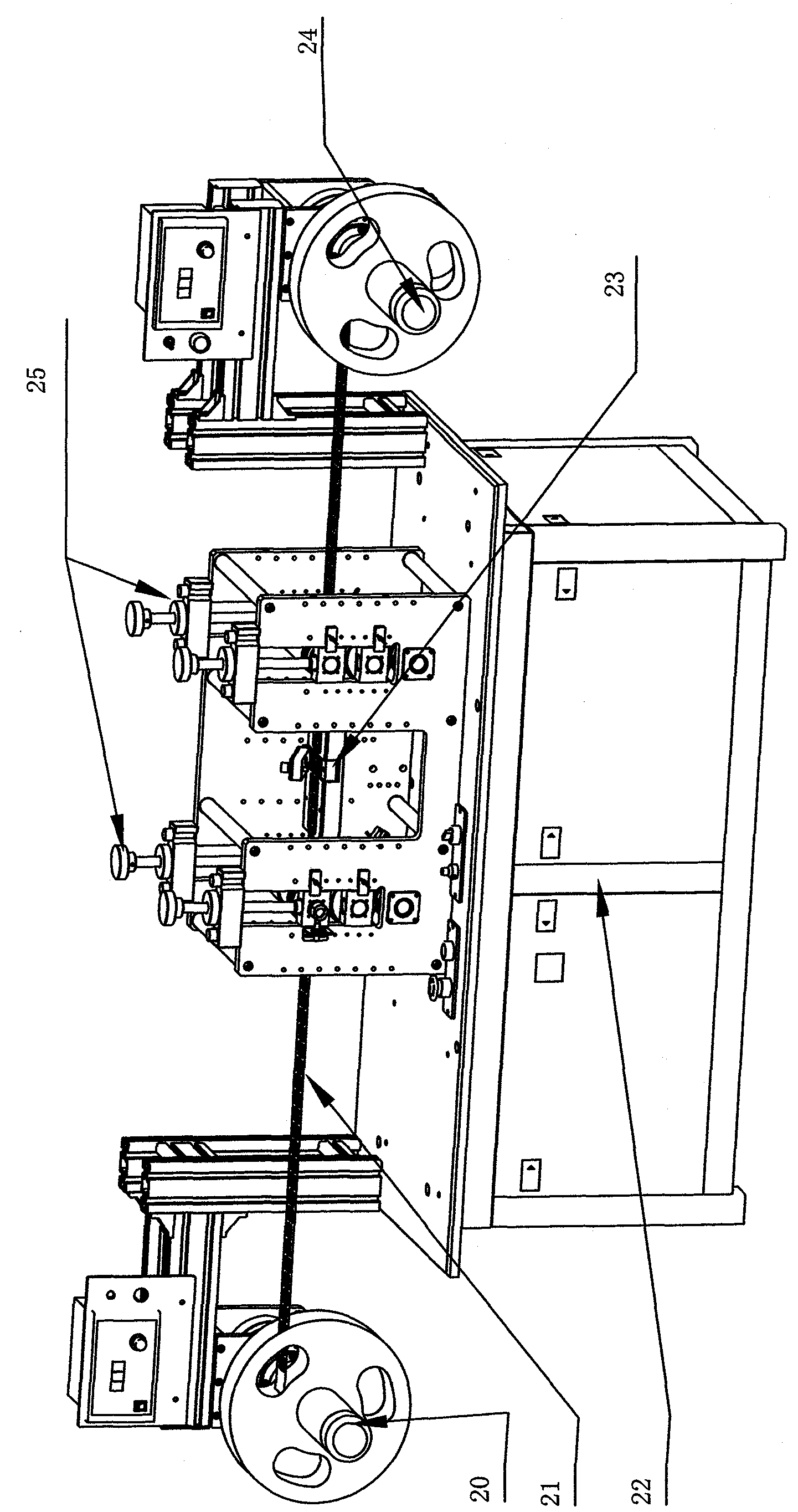

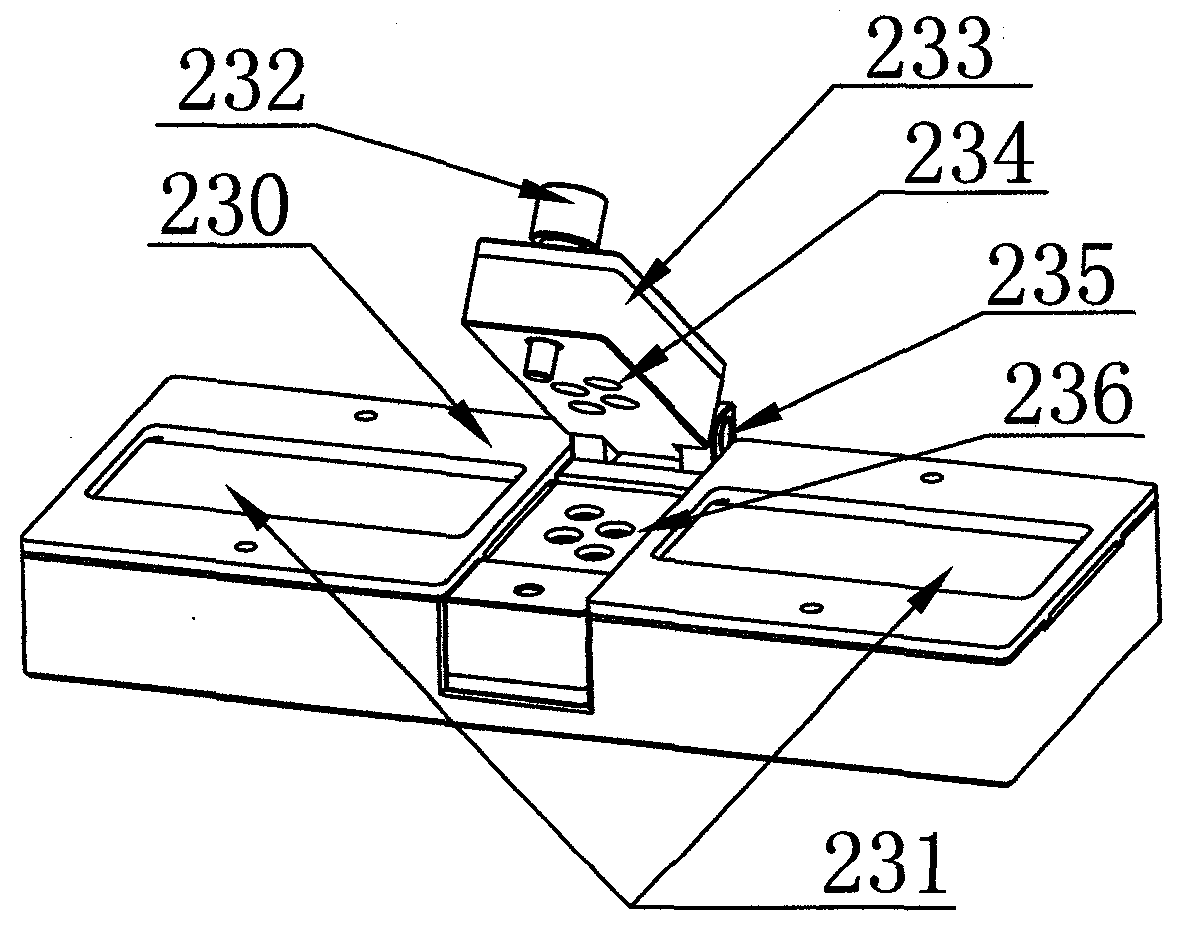

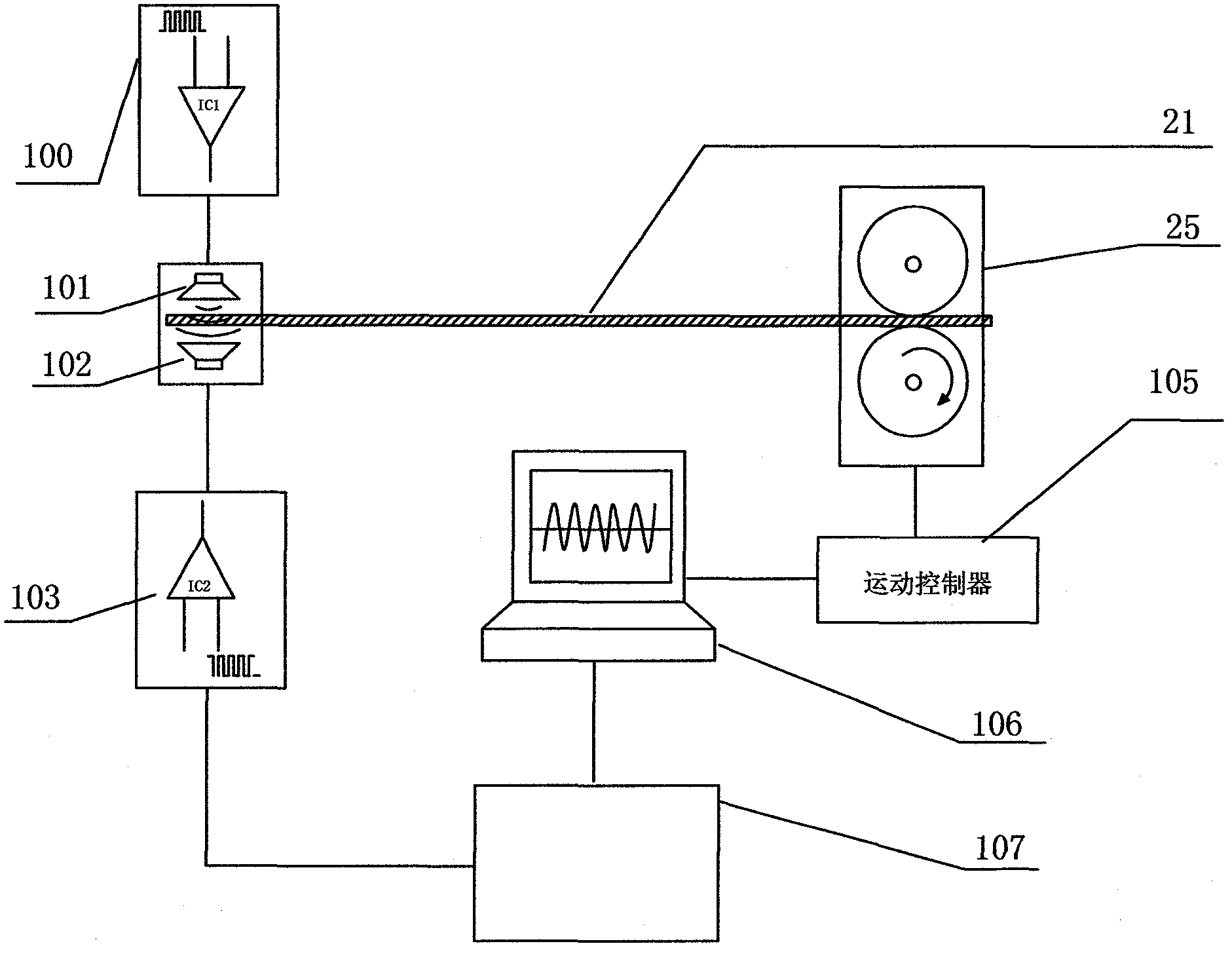

[0033] Referring to accompanying drawing, a kind of device of ultrasonic detection speaker net defect of the present invention is characterized in that: comprise frame 22 and the discharging module 20 that is loaded on the frame 22 successively, pulling module 25 and receiving module 24, in pulling module The middle part of 25 has ultrasonic detection support 23, and described ultrasonic detection support 23 comprises the lower fixed plate 230 that is fixed on pulling material module 25 middle parts and the upper fixed plate 233 that is hinged with lower fixed plate 230, and locking knob is arranged in the upper fixed plate 233 232 and at least one ultrasonic transmitting module fixing cavity 234 penetrating its plate surface, there are flow channels 231 in the lower fixing plate 230 and the number and position of the ultrasonic transmitting module fixing cavity 234 are adapted and penetrate its plate surface The ultrasonic receiving module fixed cavity 236, the ultrasonic tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com