Device and method for automatically mixing supercapacitor slurry and testing slurry dispersion

A supercapacitor, fully automatic technology, applied in chemical instruments and methods, capacitors, measuring devices, etc., can solve the problems of difficult dispersion detection, uneven dispersion of slurry, etc., and achieve good consistency, simple device and method, and uniform particle dispersion. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

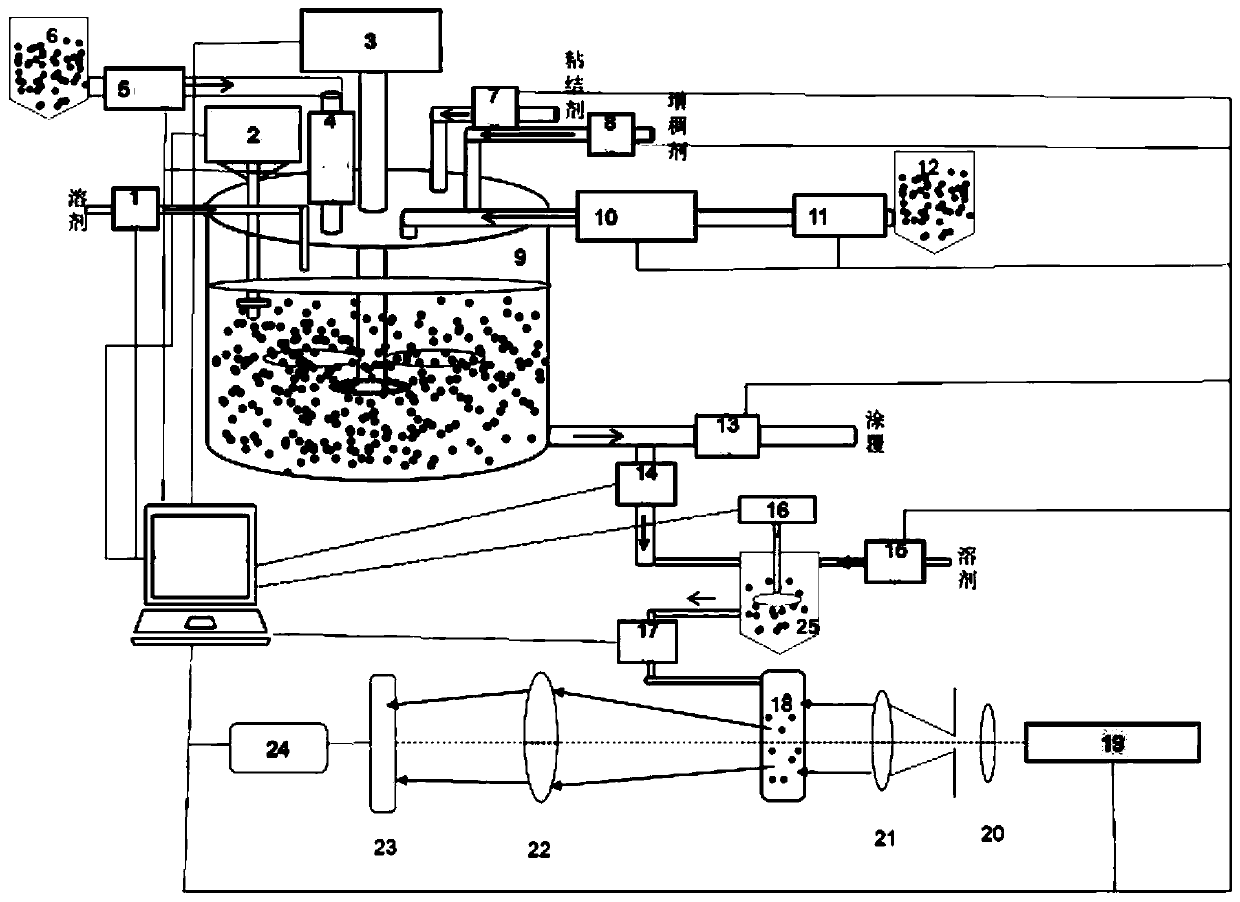

[0053] The method for fully automatic supercapacitor slurry mixing and detecting slurry dispersibility of the present embodiment comprises the following steps:

[0054] S1, open the first valve (5), then open the first pump (4), suck the porous graphene in the 8kg electrode material storage tank (6) in the mixing tank (9), then close the first valve (5 ) and the first pump (4), then open the second valve (11), and then open the second pump (10), the carbon nanotubes in the 200g conductive agent storage tank (12) are sucked in the slurry mixing kettle (9) , then close the second valve (11) and the second pump (10), and clock the third pump (7) and the fourth pump (8) at the same time, put 3L of 15% w / v PTFE aqueous solution, 200mL of 70% w / v The CMC aqueous solution is injected into the mixing tank (9), and the third pump (7) and the fourth pump (8) are closed.

[0055] S2, open the first stirring paddle (3), the stirring speed is 1800r / min, open the viscometer (2) simultaneo...

Embodiment 2

[0062] The method for fully automatic supercapacitor slurry mixing and detecting slurry dispersibility of the present embodiment comprises the following steps:

[0063] S1, open the first valve (5), then open the first pump (4), the ternary lithium (NCM) / activated carbon composite material in the 6kg electrode material storage tank (6) is sucked in the mixing tank (9), Close the first valve (5) and the first pump (4) again, open the second valve (11) again, open the second pump (10) behind, the carbon black suction in the 200g conductive agent storage tank (12) is mixed In the slurry kettle (9), close the second valve (11) and the second pump (10) again, clock in the third pump (7) and the fourth pump (8) simultaneously, and the 25% polyvinyl alcohol NMP solution of 2L 1. 200g NMP solution is injected in the mixing kettle (9), and the third pump (7) and the fourth pump (8) are closed.

[0064] S2, open the first stirring paddle (3), the stirring speed is 2300r / min, open the v...

Embodiment 3

[0071] The method for fully automatic supercapacitor slurry mixing and detecting slurry dispersibility of the present embodiment comprises the following steps:

[0072] S1, open the first valve (5), then open the first pump (4), suck the lithium iron phosphate / lithium cobaltate composite material in the 7kg electrode material storage tank (6) in the slurry mixing tank (9), and then Close the first valve (5) and the first pump (4), open the second valve (11) again, and then open the second pump (10), the vapor phase growth carbon fiber in the 300g conductive agent storage tank (12) is sucked into the mixing chamber In the slurry kettle (9), close the second valve (11) and the second pump (10) again, clock in the third pump (7) and the fourth pump (8) simultaneously, and 30% polyvinylidene fluoride ( PVDF) NMP solution, the NMP solution of 300mL are injected in the mixing kettle (9), close the 3rd pump (7) and the 4th pump (8).

[0073] S2, open the first stirring paddle (3), the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com