Method for graduating barreled nuclear waste neutron measuring device

A technology of measuring device and calibration method, which is applied in the direction of measuring device, neutron radiation measurement, radiation measurement, etc., and can solve the problems such as not providing a calibration method for barreled nuclear waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

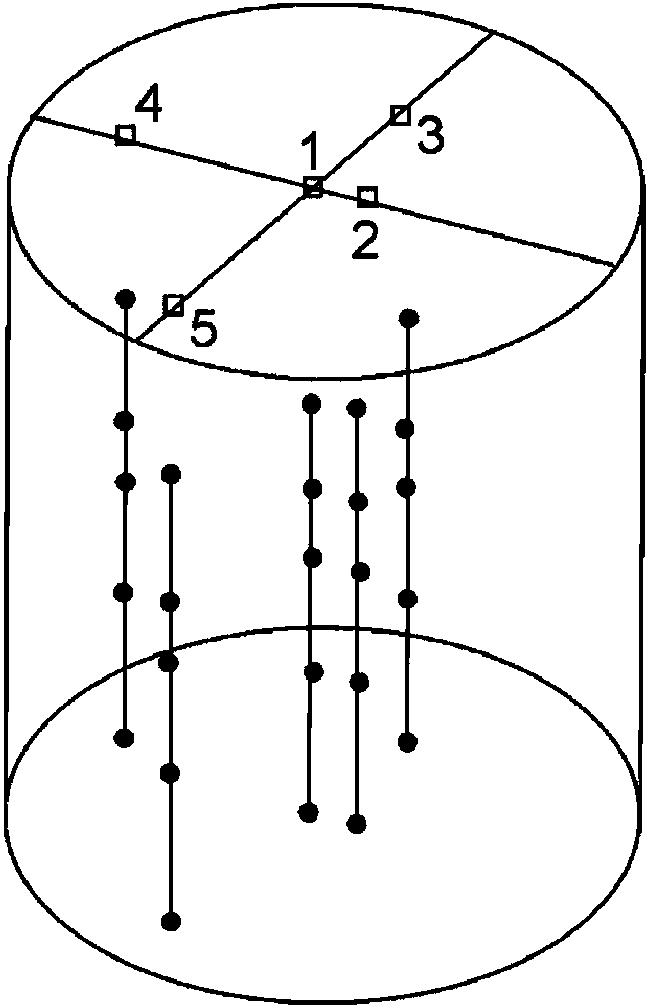

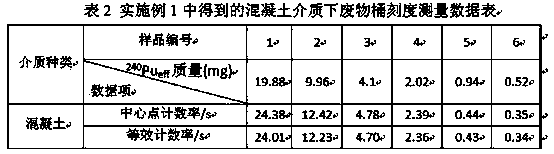

[0045] First, set the 240 Pu eff Standard samples with masses of 19.98mg, 9.96mg, 4.10mg, 2.02mg, 0.94mg, and 0.52mg were put into waste bins such as figure 1 At the 25 measuring points shown, the bucket is filled with concrete medium, and the measuring device is used to detect neutrons. The measuring time is 100s. After obtaining the counting rate of each sample at the measuring point, the equivalent counting rate of the measuring device is calculated, as shown in Table 2.

[0046]

[0047] (2) Calculate the spontaneous fission neutron count rate of different standard samples according to the equivalent count rate T sp , and build scale curve.

[0048] The curve is , the correlation coefficient is 0.9984.

Embodiment 2

[0050] First, select a waste bin filled with concrete media, place 240 Pu eff Samples with a mass of 19.88 mg were placed in figure 1 Measure the total neutron count rate at the 25 measurement points shown, and the measurement time is 50s. Each measurement point is measured 18 times and the average value is taken to obtain the count rate of each measurement point, which is substituted into the following formula: , calculate the equivalent count rate of the device under the medium condition is 24.01 / s, select the center point as the reference point, and measure the count rate of the center point is 24.38 / s, and according to the formula Calculate the correction factor at the center point =0.9848.

[0051] Then, measure 240 Pu eff The count rate of the center of samples with masses of 9.96mg, 4.10mg, 2.02mg, 0.94mg, 0.52mg respectively , the measurement time is 100s, and the measurement times are 18 times. Will Multiplied by the correction factor for this con...

Embodiment 3

[0056] The steps and methods used in Example 2 are the same, except that the medium condition and measurement time are changed, and the measurement time is 200s. As shown in Table 4:

[0057]

[0058] The obtained scale relationship curve is shown in Table 5:

[0059]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com