Touch screen, manufacturing method of touch screen and display device

A touch screen and touch electrode technology, applied in the direction of instruments, electrical digital data processing, data processing input/output process, etc., can solve the problems of low production efficiency and many times of mask board, so as to improve manufacturing efficiency and reduce production cost , the effect of reducing the number of composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

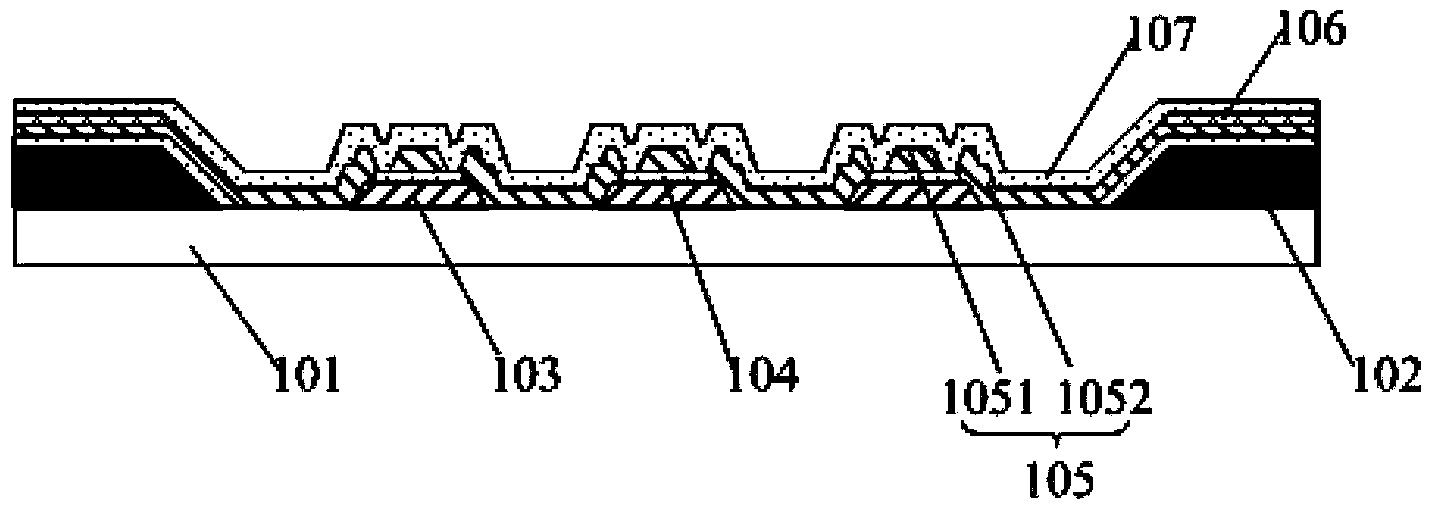

[0025] The specific implementation manners of the touch screen provided by the embodiments of the present invention, its manufacturing method and the display device will be described in detail below with reference to the accompanying drawings.

[0026] The film thickness and area size and shape of each layer in the drawings do not reflect the real scale, and the purpose is only to schematically illustrate the content of the present invention.

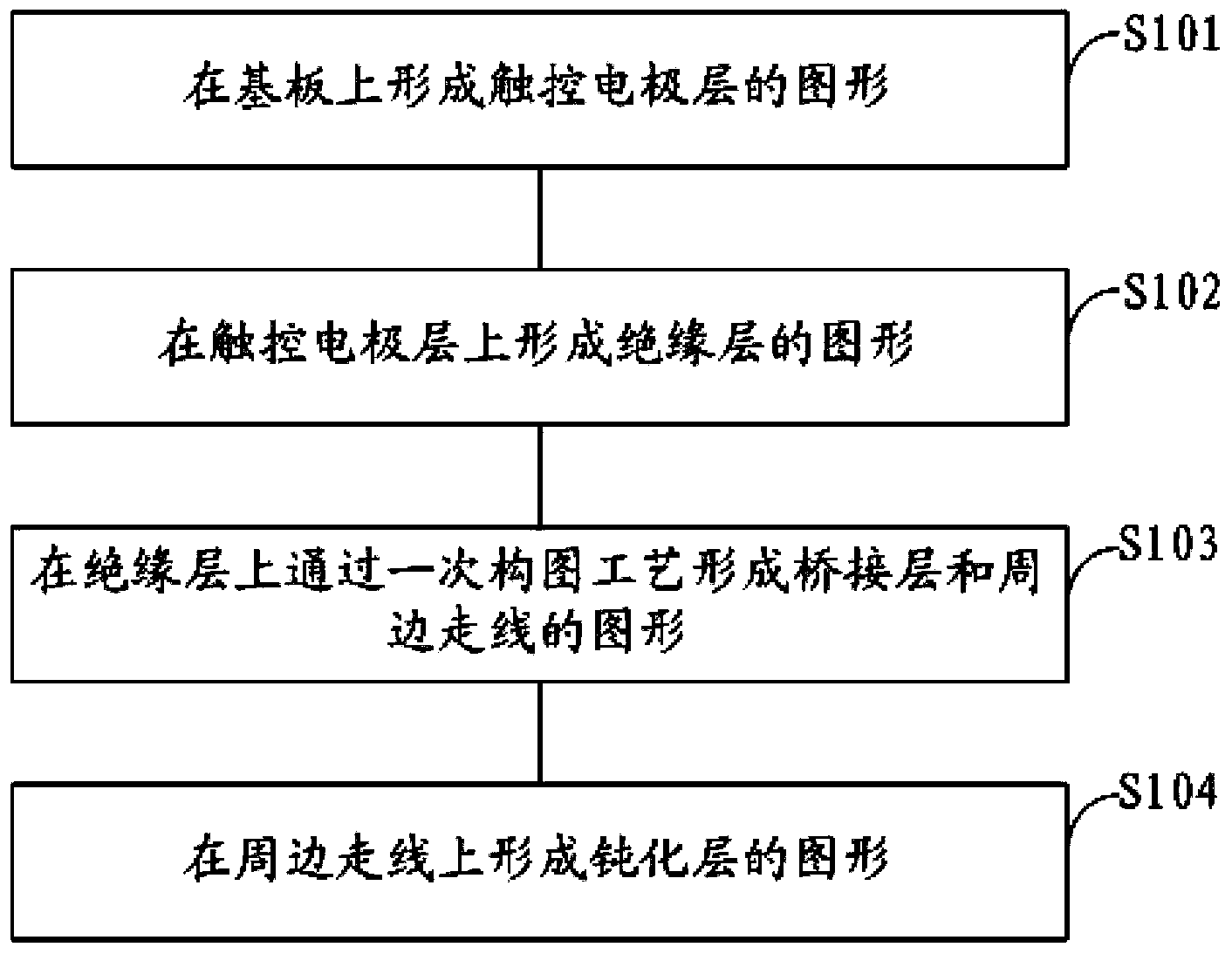

[0027] A method for manufacturing a touch screen provided by an embodiment of the present invention, such as figure 2 As shown, it specifically includes the following steps:

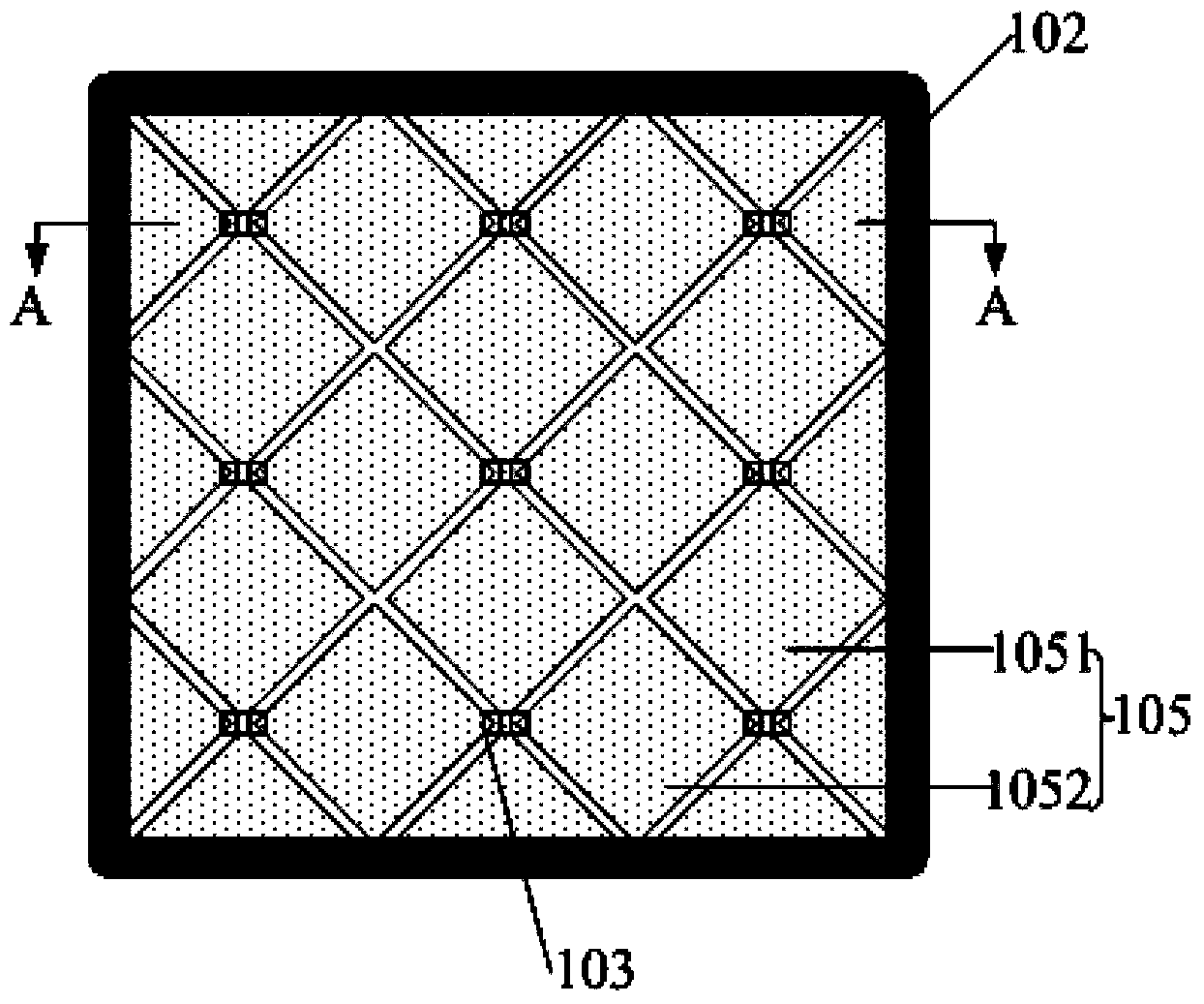

[0028] Step S101, forming a pattern of the touch electrode layer 3 on the substrate 1, the touch electrode layer 3 includes touch sensing electrodes 31 and touch driving electrodes 32 that are intersected and insulated from each other, such as Figure 3b As shown, the touch electrode layer 3 has patterns in both the touch area A and the non-touch area B;

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com