A kind of preparation method and application of nano tio2(b)/carbon composite fiber for negative electrode of lithium ion battery

A lithium-ion battery, carbon composite technology, applied in the fields of electrochemistry and material chemistry, to achieve the effects of low production cost, guaranteed purity, and controllable component structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

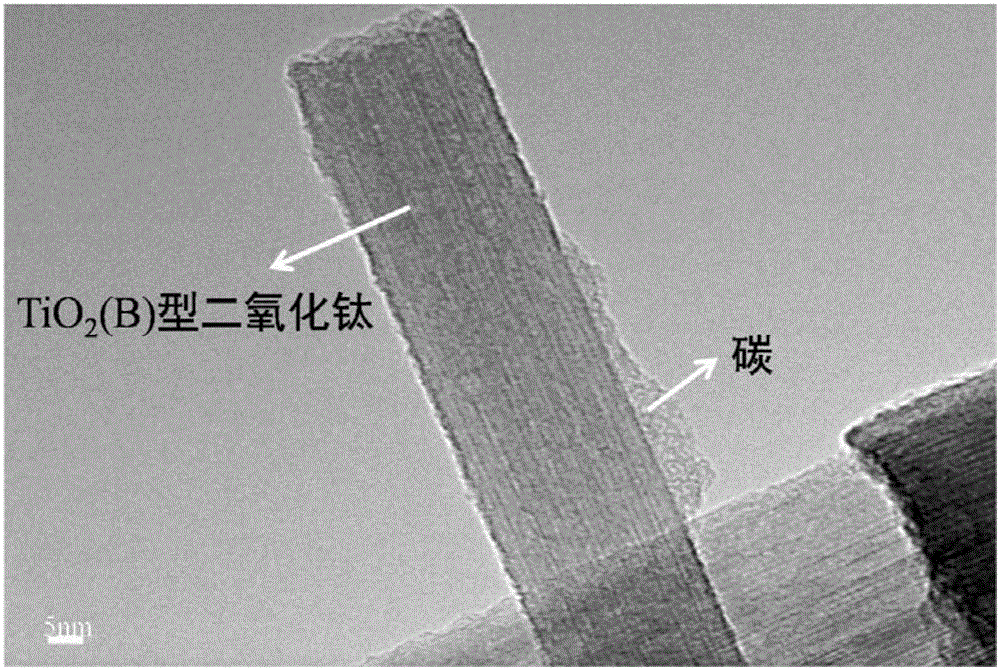

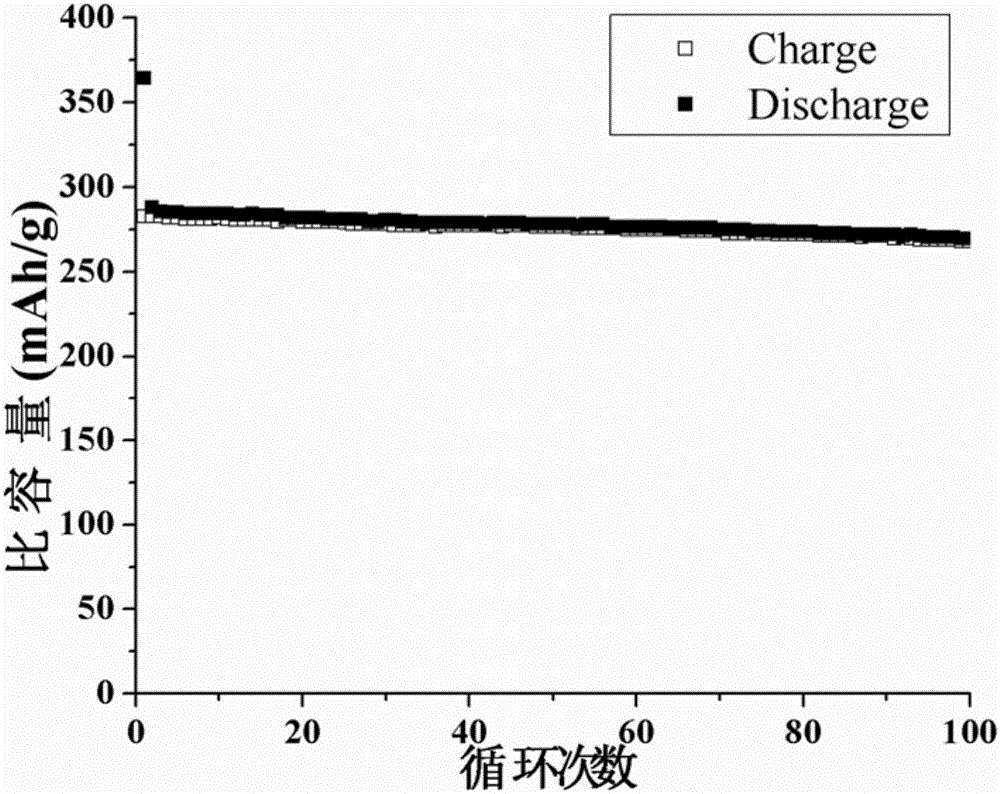

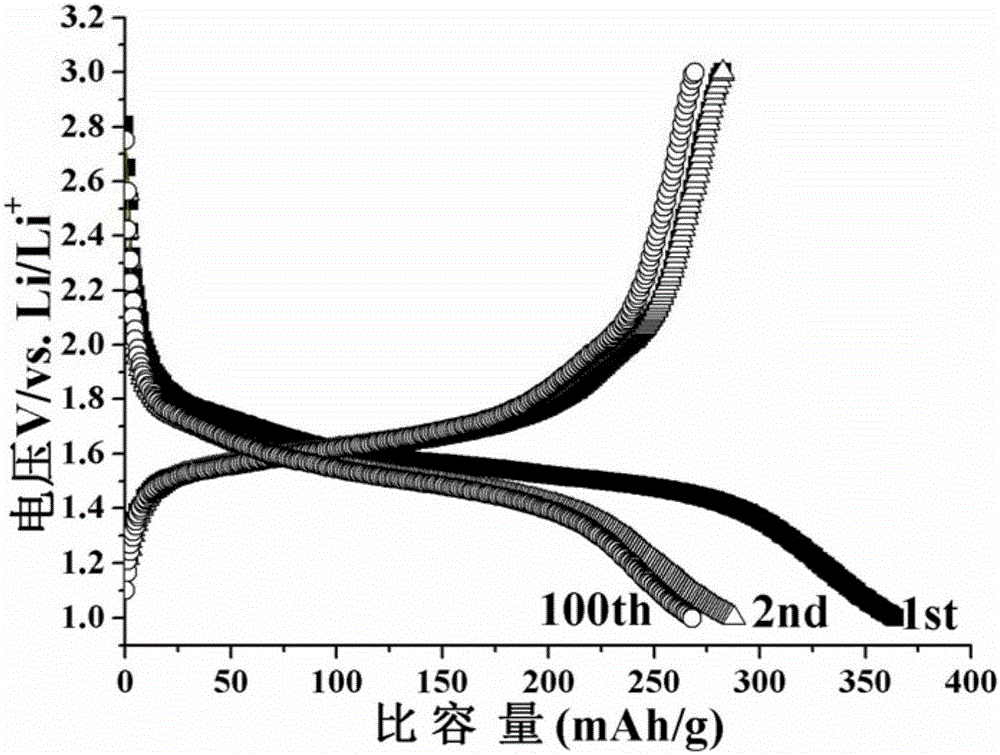

[0018] Embodiment 1 prepares TiO 2 (B) / C composite fiber Ⅰ

[0019] Under the condition of magnetic stirring, 0.8g of tetrabutyl titanate and 0.4g of PVP were dissolved in a mixed solution of 6mL of ethanol, 2mL of acetic acid and 1mL of N,N-dimethylformamide, mixed and stirred evenly. Take 10mL of the solution with a syringe, the front of the spinneret is a copper mesh collection device, the voltage is 10kV, and the flow rate is 1.0mL / h. After spinning, the TBT / PVP precursor fiber was obtained, the fiber membrane was carefully removed, and vacuum dried at 60°C. Then, under the protection of nitrogen, the temperature was raised to 300° C. for calcination at a rate of 2° C. / min, and the temperature was kept for 120 minutes.

[0020] Dissolve 0.35 g of the calcined sample in 10M NaOH solution to obtain a suspension. React in a closed 50mL hydrothermal kettle at 200°C for 24 hours. After stopping the reaction, wash the precipitated product with 0.1M hydrochloric acid and deion...

Embodiment 2

[0022] Embodiment 2 prepares TiO 2 (B) / C composite fiber Ⅱ

[0023] Under magnetic stirring conditions, 0.8 g of tetrabutyl titanate and 0.4 g of PVP were dissolved in a mixed solution of 5 mL of ethanol, 2 mL of acetic acid and 1 mL of N,N-dimethylformamide. Mix and stir well. Take 10mL of the solution with a syringe, the front of the spinneret is a copper mesh collection device, the voltage is 11kV, and the flow rate is 1.0mL / h. After spinning, the TBT / PVP precursor fiber was obtained, the fiber membrane was carefully removed, and vacuum dried at 60°C. Then, under the protection of nitrogen, the temperature was raised to 500° C. for calcination at a rate of 2° C. / min, and the temperature was kept for 120 minutes.

[0024] Dissolve 0.4 g of the calcined sample in 10M NaOH solution to obtain a suspension, react in a closed 50mL hydrothermal kettle at 180°C for 24 hours, stop the reaction, and wash the precipitated product with 0.1M hydrochloric acid and deionized water Was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com