Printed circuit board

A printed circuit board and current path technology, applied in the direction of printed circuit components, etc., can solve the problem that the position of the power supply terminal and the load terminal cannot be adjusted smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

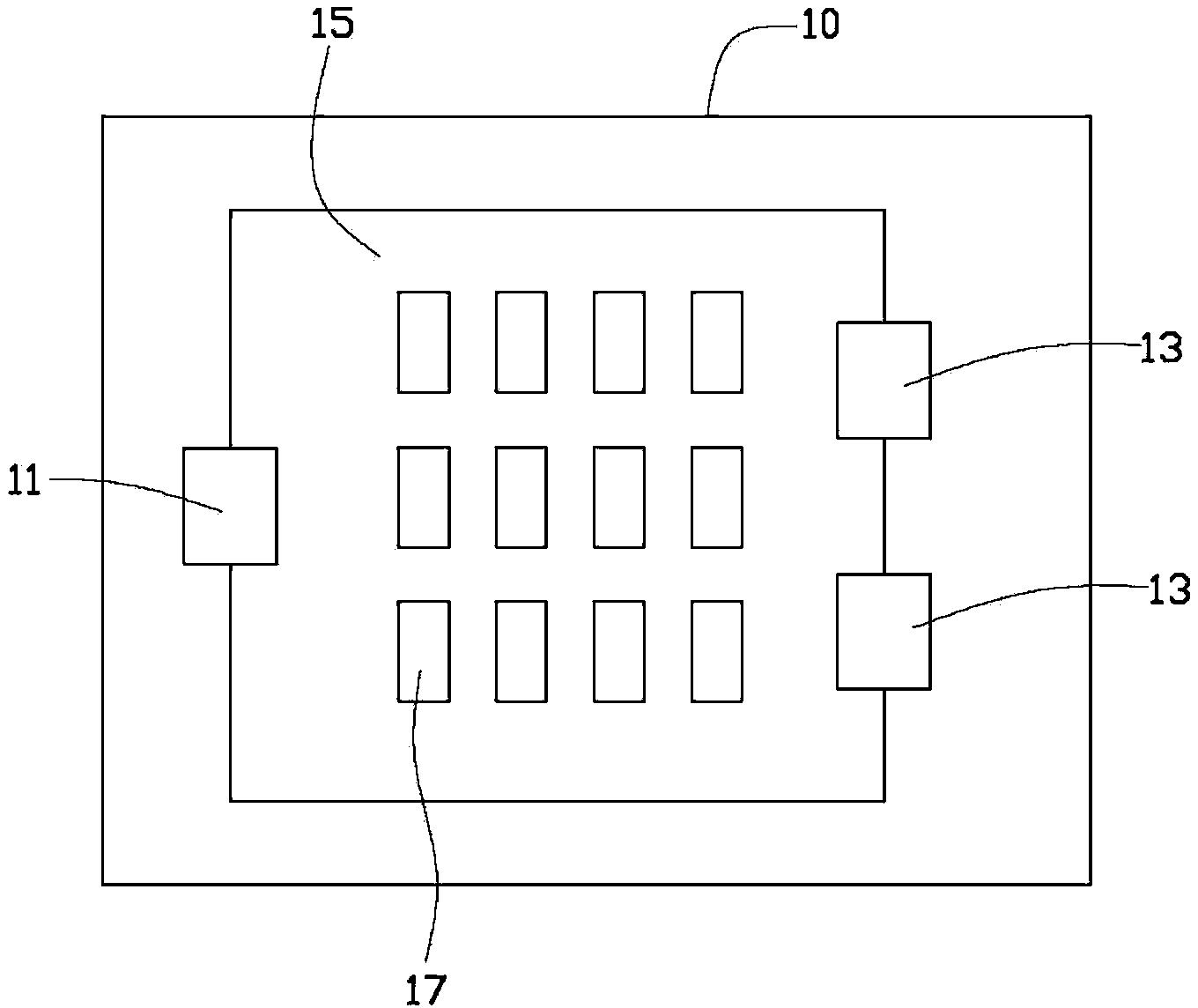

[0011] see figure 1 , the printed circuit board 10 of the preferred embodiment of the present invention includes a power supply 11 , a load 13 , a copper foil 15 and a metal foil 17 . The power supply 11 , the load 13 and the copper foil 15 are electrically connected in sequence, and the current output by the power supply 11 flows to the load 13 through the copper foil 15 .

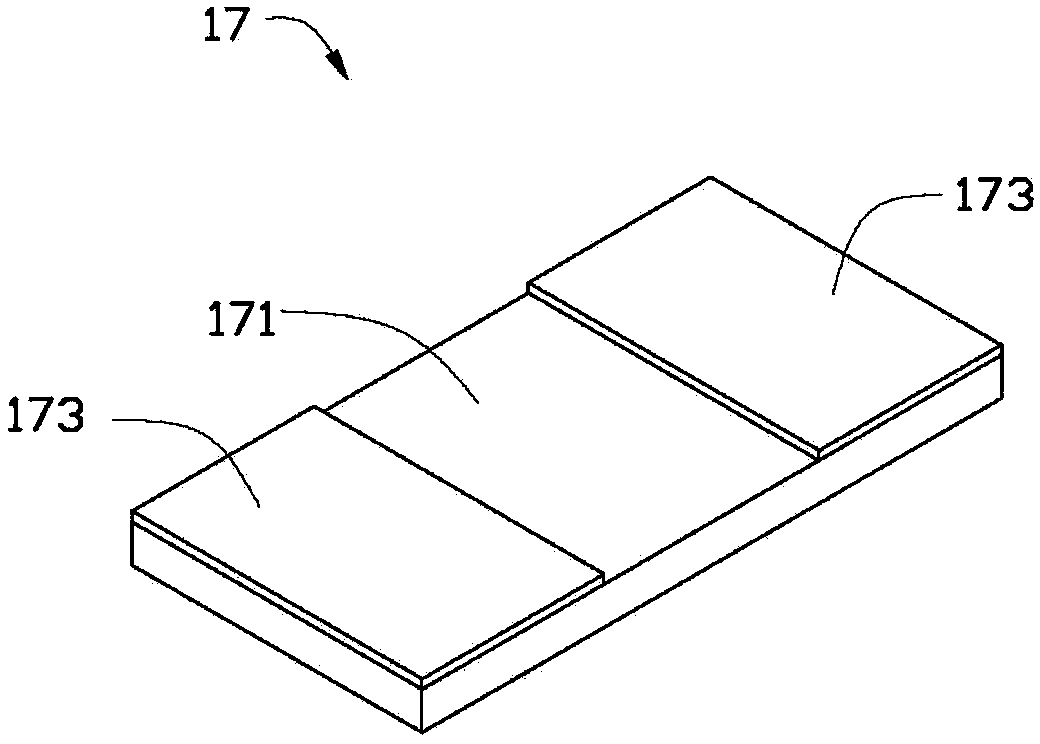

[0012] Please also refer to figure 2 , the metal foil 17 is welded on the copper foil 15 by surface mount technology (Surface Mount Technology, SMT). Specifically, the metal foil 17 includes a soldering surface 171 . Soldering pads 173 are provided on the soldering surface 171 . In this preferred embodiment, there are two welding pads 173 , which are respectively arranged at opposite ends of the welding surface 171 . The surface of the metal foil 17 except the pad 173 is covered with insulating varnish. The metal foil 17 is welded on the copper foil 15 through the pad 173. In this way, the metal foi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com