Wheat Stubble Soybean No-Till Seeder

A seeder, soybean technology, applied in the direction of agricultural machinery and equipment, agricultural machinery and implements, shovels, etc., can solve the problems of increasing agricultural production costs, and achieve the effects of saving energy and time, being easy to accept, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

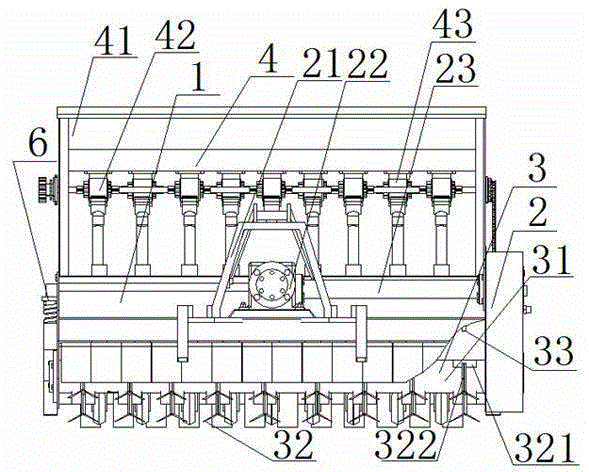

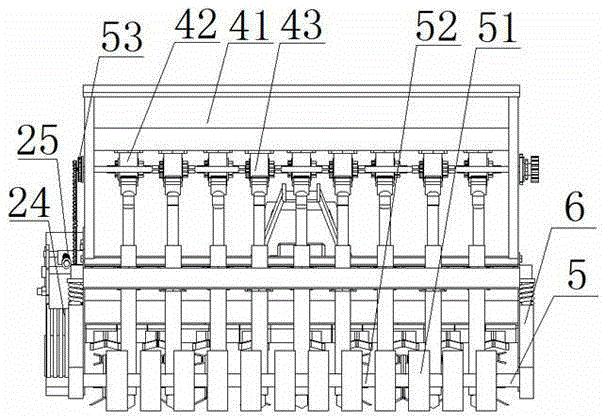

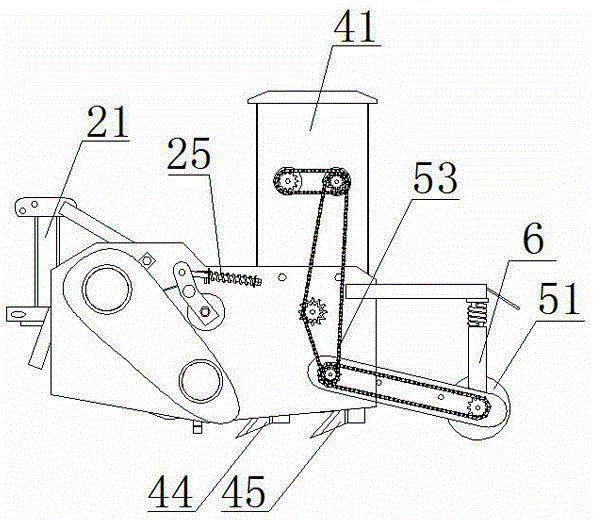

[0017] like figure 1 , 2 , The wheat stubble removal soybean no-tillage planter shown in 3 and 4 includes a frame 1 and a front transmission device 2 installed on the frame 1, a stubble removal mechanism 3, a fertilization and seeding mechanism 4, a rear transmission device 5, and the stubble removal mechanism 3 includes a stubble removal knife shaft 31, a stubble removal knife 32 installed on the stubble removal knife shaft 31, and a fixed knife 33 installed on the frame 1, wherein the stubble removal knife 32 is Y-shaped, and its Y-shaped opening corresponds to the fixed knife 33, and the stubble removal knife The shaft 31 is connected to the front transmission device 2; the fertilization and seeding mechanism 4 includes a fertilization seeding box 41, a fertilization speed controller 42 connected to the fertilization seeding box and a seeding speed controller 43, and a fertilization opener connected to the fertilization speed controller 44. Connect the seeding ditch opener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com