The driving structure of the connecting rod of the beverage extraction device

An extraction device and connecting rod drive technology are applied in the field of drive structures for driving movable parts in beverage extraction devices to move back and forth, which can solve the problems of long piston movement stroke, low work efficiency, and long total movement path, and achieve the purpose of driving parts. The effect of moving forward, fast moving parts forward, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

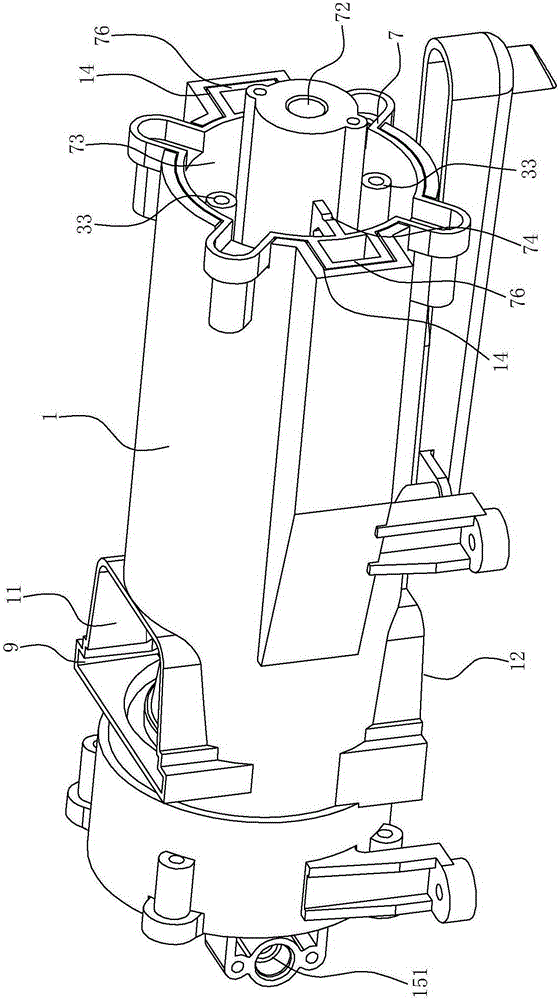

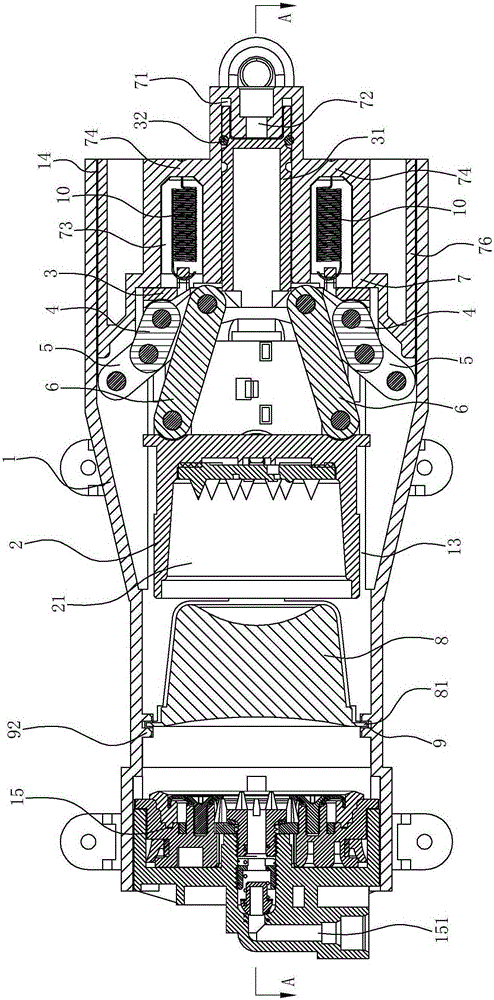

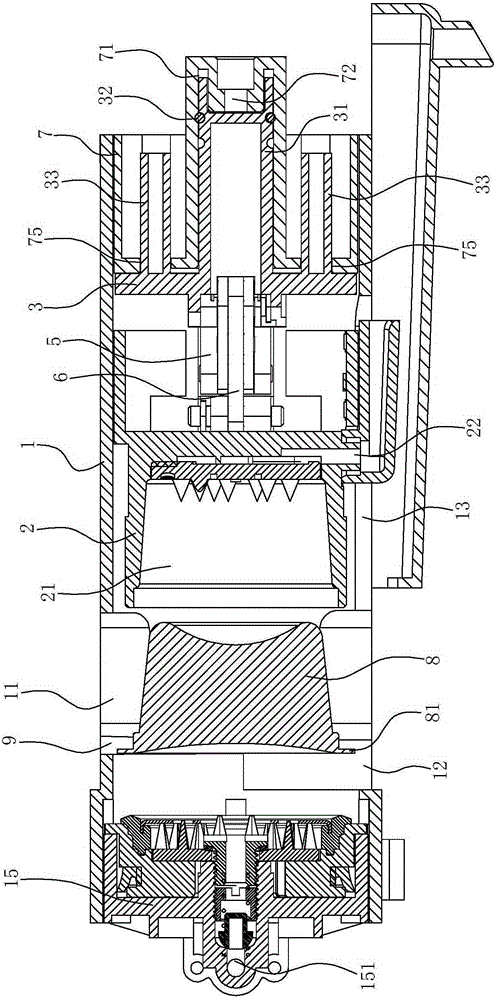

[0035] Such as Figure 1-13 Shown is a preferred embodiment of the present invention.

[0036] A driving structure of a machine link for a beverage extracting device, comprising a machine base 1 with a packing opening 11 and a bag dropping opening 12, and a machine part 2 constrained in the machine base that can slide back and forth. In this embodiment, the machine part 2 The front part of the machine base has an accommodating cavity 21 for accommodating the beverage pack 8, and a beverage outlet channel 22 communicating with the accommodating cavity 21. As a complete extraction system, the front end of the base 1 is fixed with a fixed part 15, and the fixed part 15 There is a hot water channel 151 for hot water to pass through, and the extraction chamber for accommodating the beverage bag 8 can be formed after the mechanism 2 and the fixed mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com