A device for rolling turf in a turf plantation field

A planting field and turf technology, which is applied in lawn growth, plant cultivation, botanical equipment and methods, etc., can solve the problems of high labor intensity and low efficiency of rolling turf, and achieve the effect of reducing labor intensity and improving the efficiency of turf rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

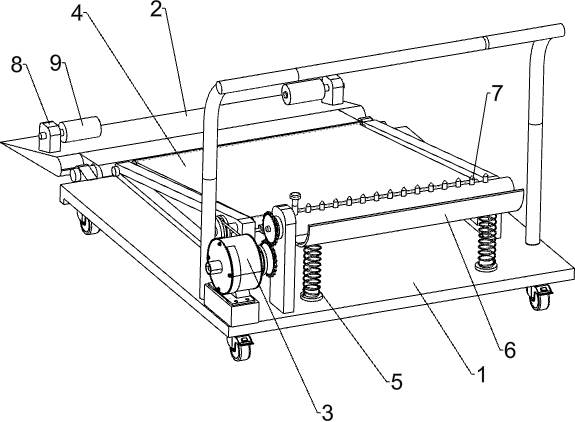

[0024] A device for rolling turf in a turf plantation field, such as Figure 1-3 As shown, it includes a cart 1, a shovel plate 2, a turf rolling mechanism 3, a transmission mechanism 4, a support spring 5 and an arc guide plate 6. The rear side of the cart 1 is hingedly connected with the shovel plate 2. The top of the cart 1 The turf rolling mechanism 3 is installed on the rear side, and the top of the cart 1 on the front side of the turf rolling mechanism 3 is installed with a conveying mechanism 4. The conveying mechanism 4 is hingedly connected with an arc guide plate 6, and the left and right sides of the bottom of the arc guide plate 6 are both. A support spring 5 is connected, and the bottom end of the support spring 5 is connected with the top of the cart 1 .

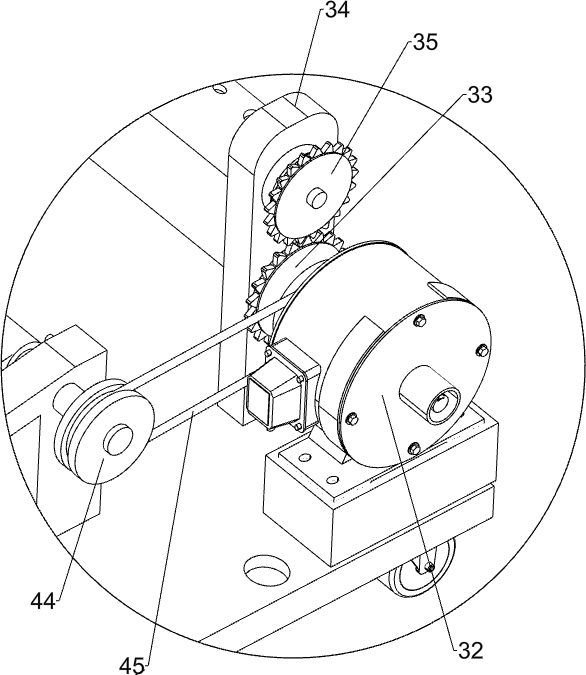

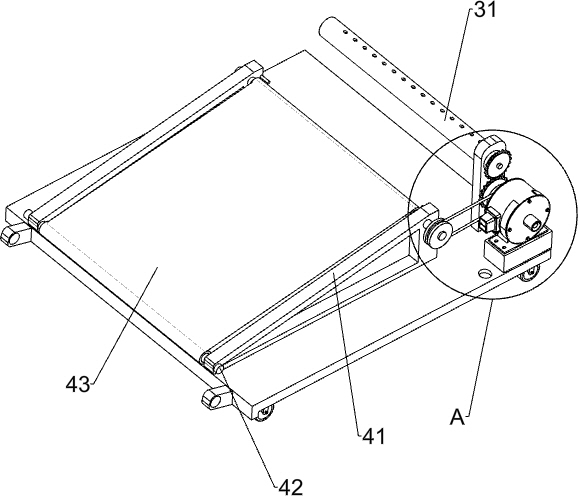

[0025] The turf rolling mechanism 3 includes a rotating shaft 31, a motor 32, a first gear 33, a mounting seat 34 and a second gear 35. A motor 32 is installed on the top rear side of the cart 1, and the output...

Embodiment 2

[0029] On the basis of Example 1, as figure 1 and Figure 4 As shown, it also includes a turf-rolling auxiliary mechanism 7, and the turf-rolling auxiliary mechanism 7 includes a return spring 71, a mounting plate 72, a nail 73 and a handle 74, and the inner wall of the rotating shaft 31 is connected with a plurality of return springs 71 at regular intervals. A mounting plate 72 is connected between the ends of the return springs 71 , and a plurality of nails 73 are connected to the mounting plate 72 at even intervals. , the end of the handle 74 penetrates the rotating shaft 31 , and the handle 74 is located on the left side of the leftmost nail 73 .

[0030] The nails 73 can be stuck on the turf to fix the front end of the turf on the rotating shaft 31, so that the rotating shaft 31 can easily and quickly roll the turf into a ball, thereby further improving the efficiency of rolling the turf; when the turf is to be taken off , press the handle 74 to make the mounting plate ...

Embodiment 3

[0032] On the basis of Example 2, as figure 1 As shown, it also includes a support 8 and an electric wheel 9 , the left and right sides of the top of the shovel plate 2 are connected with the support 8 , and the inner side of the support 8 is installed with an electric wheel 9 .

[0033] Manually start the electric wheel 9 to make the electric wheel 9 rotate counterclockwise. The counterclockwise rotation of the electric wheel 9 can make the turf on the shovel 2 move forward quickly and smoothly. When the turf is all rolled up, close the two electric wheels 9 That's it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com