Normal pressure reaction kettle

A reaction kettle and atmospheric pressure technology, applied in the field of chemical equipment reaction kettles, can solve the problems of too much material being reclaimed, lower yield of the final product, waste, etc., and achieve the effects of uniform mixing of materials, controllable amount of material being reclaimed, and improved yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better understand the present invention, the present invention will be described below in conjunction with examples.

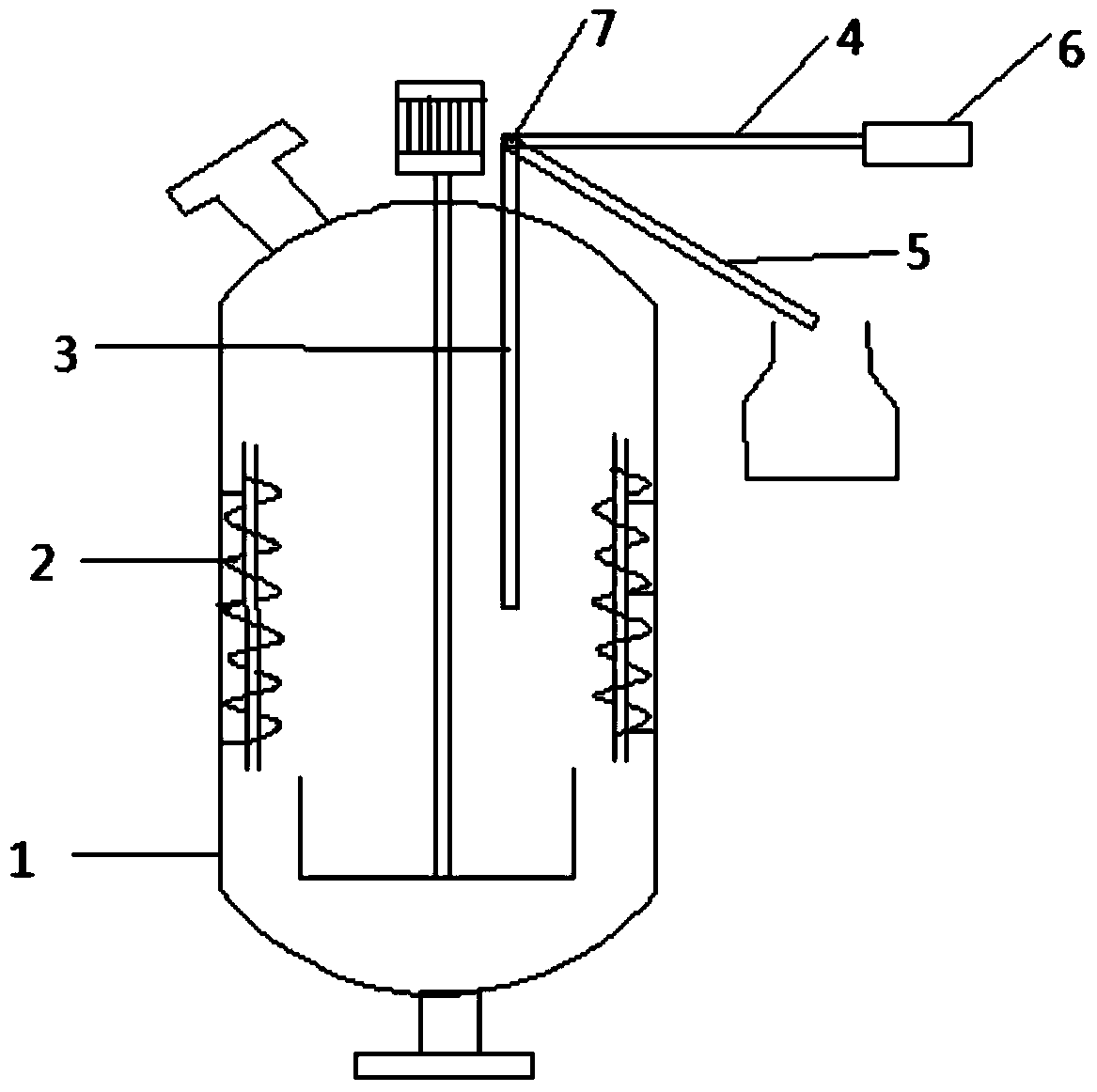

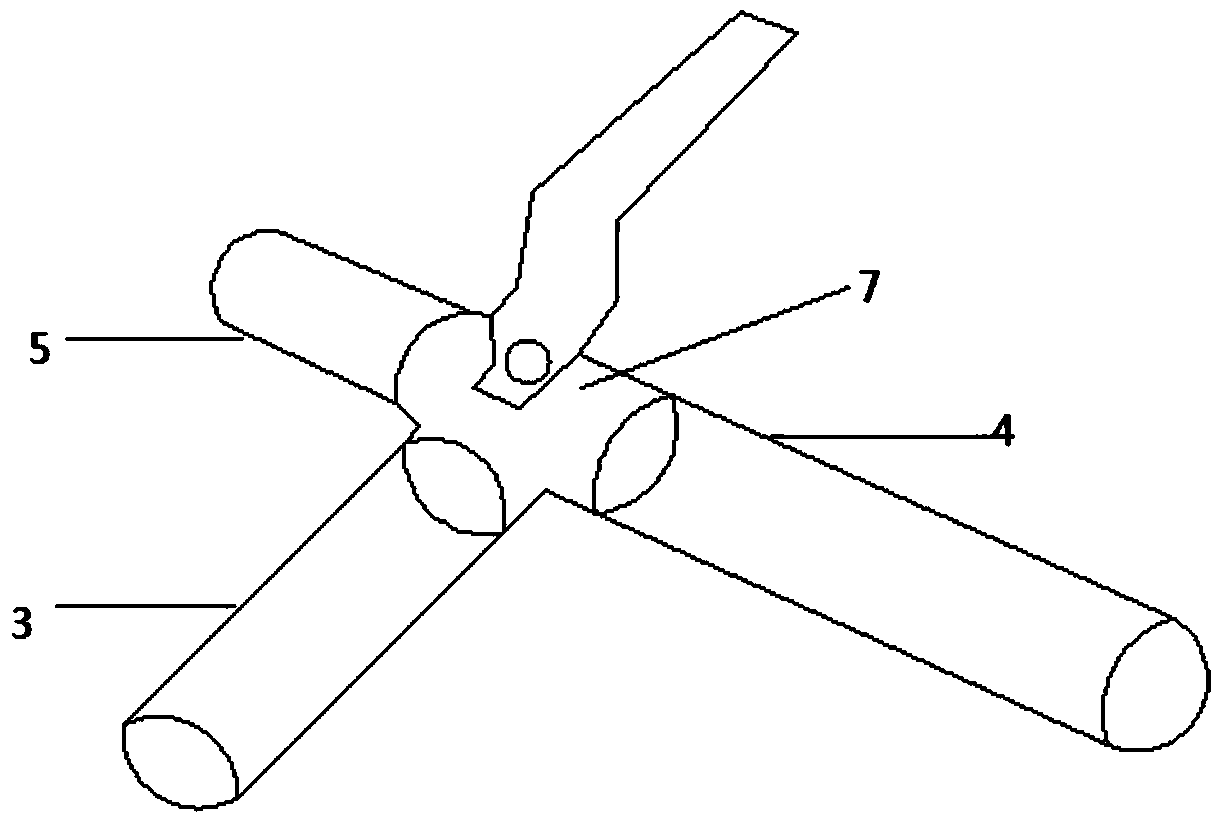

[0020] Such as figure 1 , figure 2 Shown, a kind of normal pressure reactor comprises still body 1, and the inner wall of described still body 1 is provided with more than one helical deflector 2, and the top of described still body 1 is provided with a through hole, and described still body A drainage tube 3 is arranged inside the body 1 , and one end of the drainage tube 3 passes through the through hole and connects a vacuum tube 4 and a discharge tube 5 through a three-way valve 7 .

[0021] Preferably, the spiral deflector 2 is single spiral or double spiral, figure 1 A schematic diagram of a single helical baffle. Compared with the existing plate-shaped spiral deflector, the spiral deflector 2 can undergo multiple collisions after the material collides with the spiral deflector 2, and can form a larger turbulent flow, and the mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com