Machine tool for machining long bars

A machine tool and long rod technology, applied in the field of machining machine tools, can solve problems such as time-consuming, large horizontal span, and inconvenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

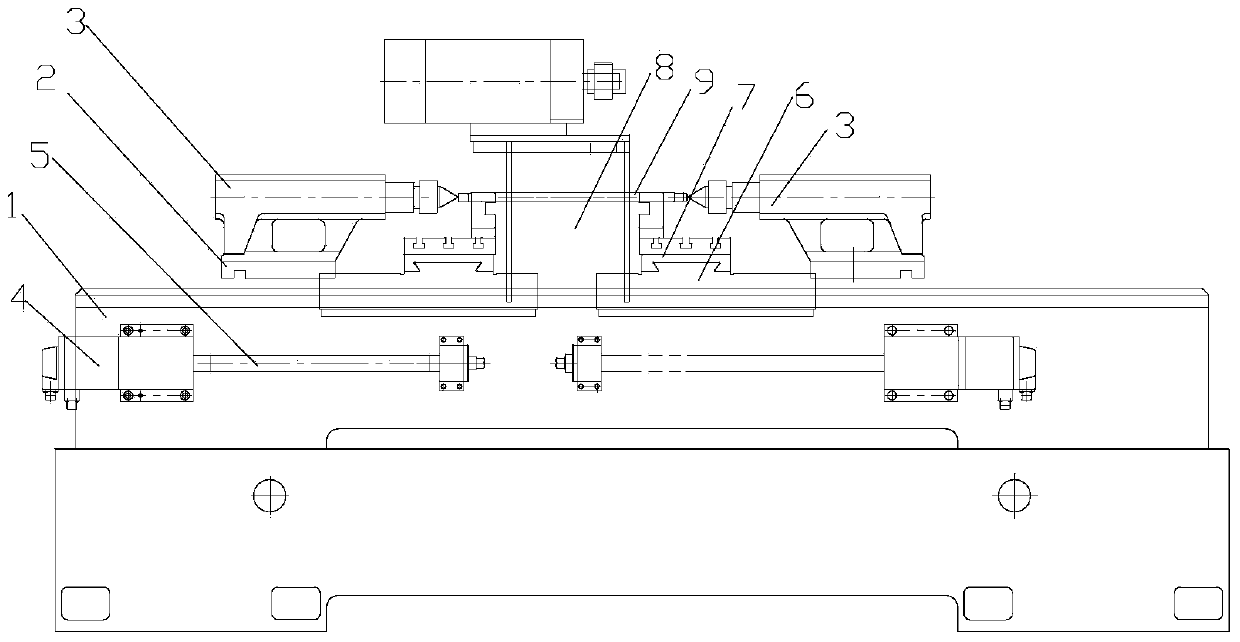

[0013] The machine tool for processing long bars of the present invention includes a bed 1, a clamping device, a driving device, and a guiding device.

[0014] The guiding device is mainly a guide rail 2 fixedly connected to the bed 1 so as to be used for sliding connection of the tailstock 3 in the clamping device. The driving device includes a large pallet 6 connected to the ball screw 5 of the z-axis servo motor 4, and a small pallet 7 that can be slidably connected to the large pallet 6 on the bed 1 to clamp the tool on the small pallet 7, so as to control the movement of the large pallet 6 and the small pallet 7, and realize the coordinate transformation between the tool and the workpiece 9 to be processed. The clamping device is fixedly arranged on the bed 1, and mainly includes a chuck box 8 fixedly connected to the bed 1 and a tailstock 9 that can be relatively slidably connected to the guide rail 2. In order to facilitate efficient processing of long bar workpieces, The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com