PXE piston turnover box

A turnover box and piston technology, which is applied to metal processing machinery parts, protection and storage accessories, metal processing equipment, etc., can solve the problems of messy arrangement of pistons, lower production efficiency, and troublesome cleaning, so as to reduce production costs and improve production efficiency , The effect of convenient clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

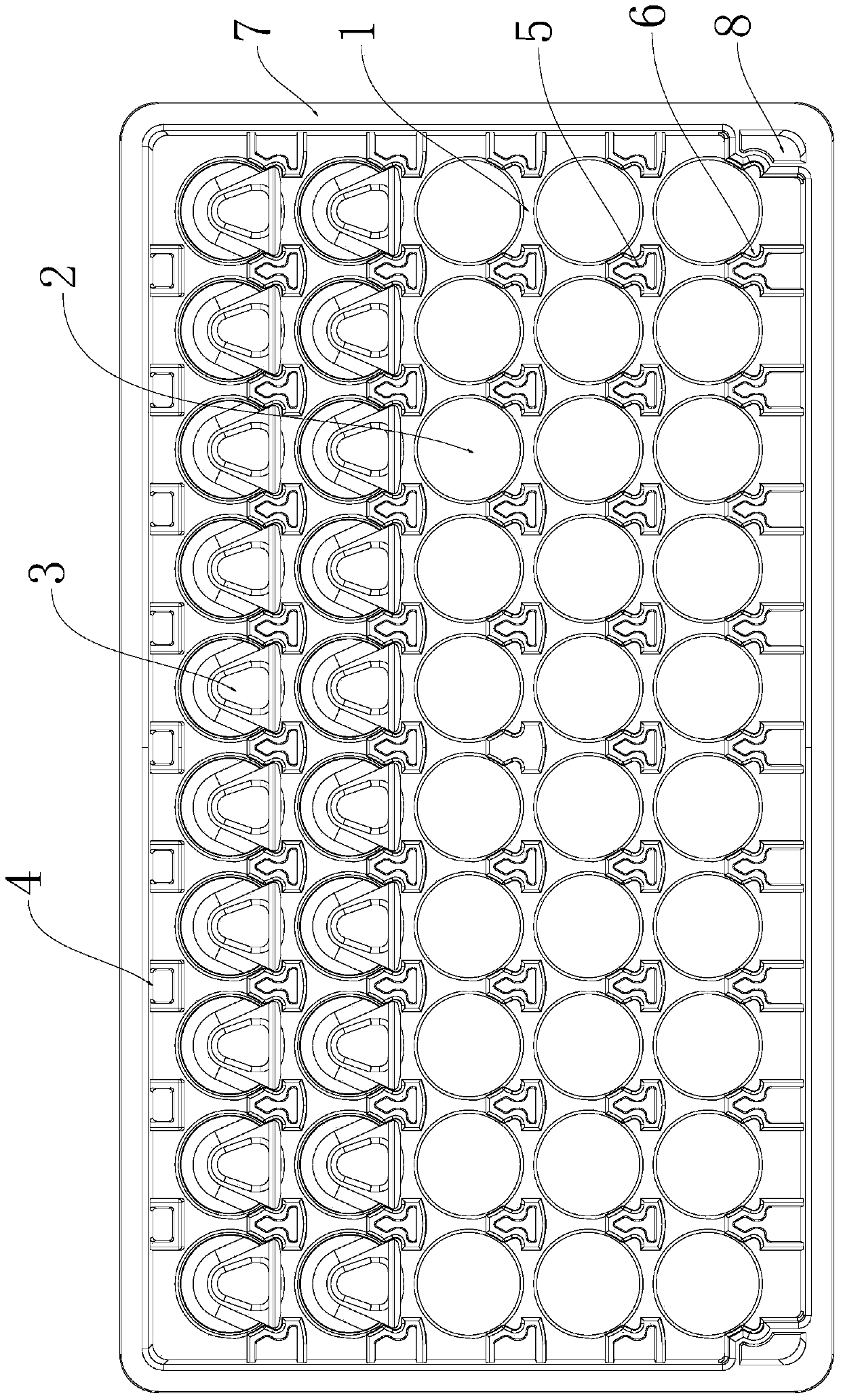

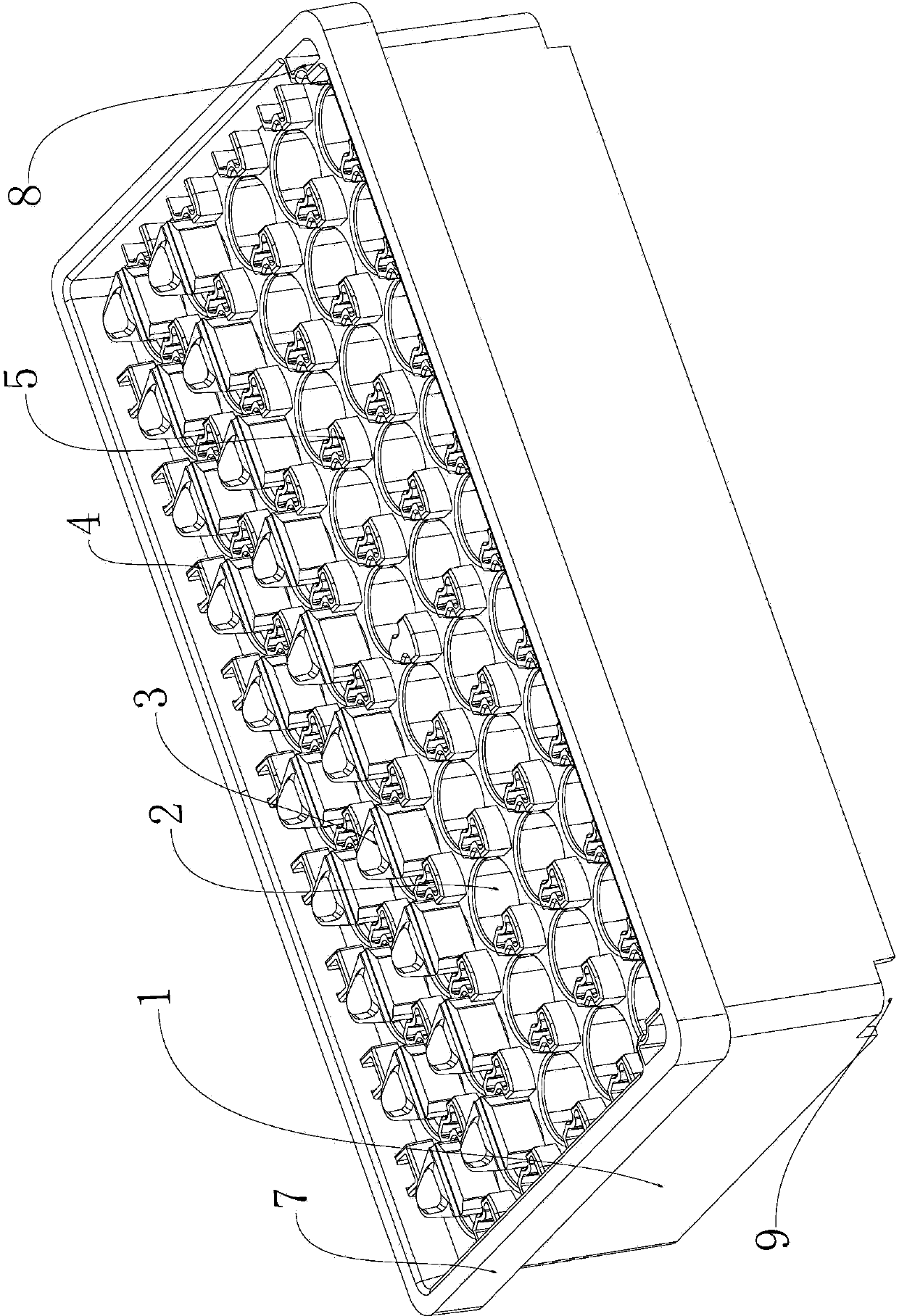

[0013] Such as figure 1 , figure 2 As shown, the PXE piston turnover box described in this embodiment includes a box body 1, and there are a plurality of piston placement positions 2 in an evenly spaced array in the case body 1. The piston placement positions 2 are hollow structures, and the piston placement positions The inner diameter of the piston 2 is the same as the outer diameter of the piston 3, and a rectangular protrusion 4 is provided at the interval between the piston placement positions 2 on one side of the box body 1, and a rectangular protrusion 4 is provided at the junction of the four piston placement positions 2 and with each other. A positioning protrusion 5 is provided at the interval between the piston placement positions 2 on the corresponding side of the lifter 4, and a half positioning protrusion 5 is provided at the interval between the piston placement positions 2 on the other two sides. , and the directions of all the positioning protrusions 5 are t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com