Walking stepless speed change adjusting mechanism for lawn mower

A technology of stepless speed change and adjustment mechanism, which is applied in the direction of mechanical equipment, control devices, belts/chains/gears, etc. It can solve the problems of short service life of the belt, heavy backing, and large space occupation, and achieves a practical and firm structure and avoids walking Weak, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

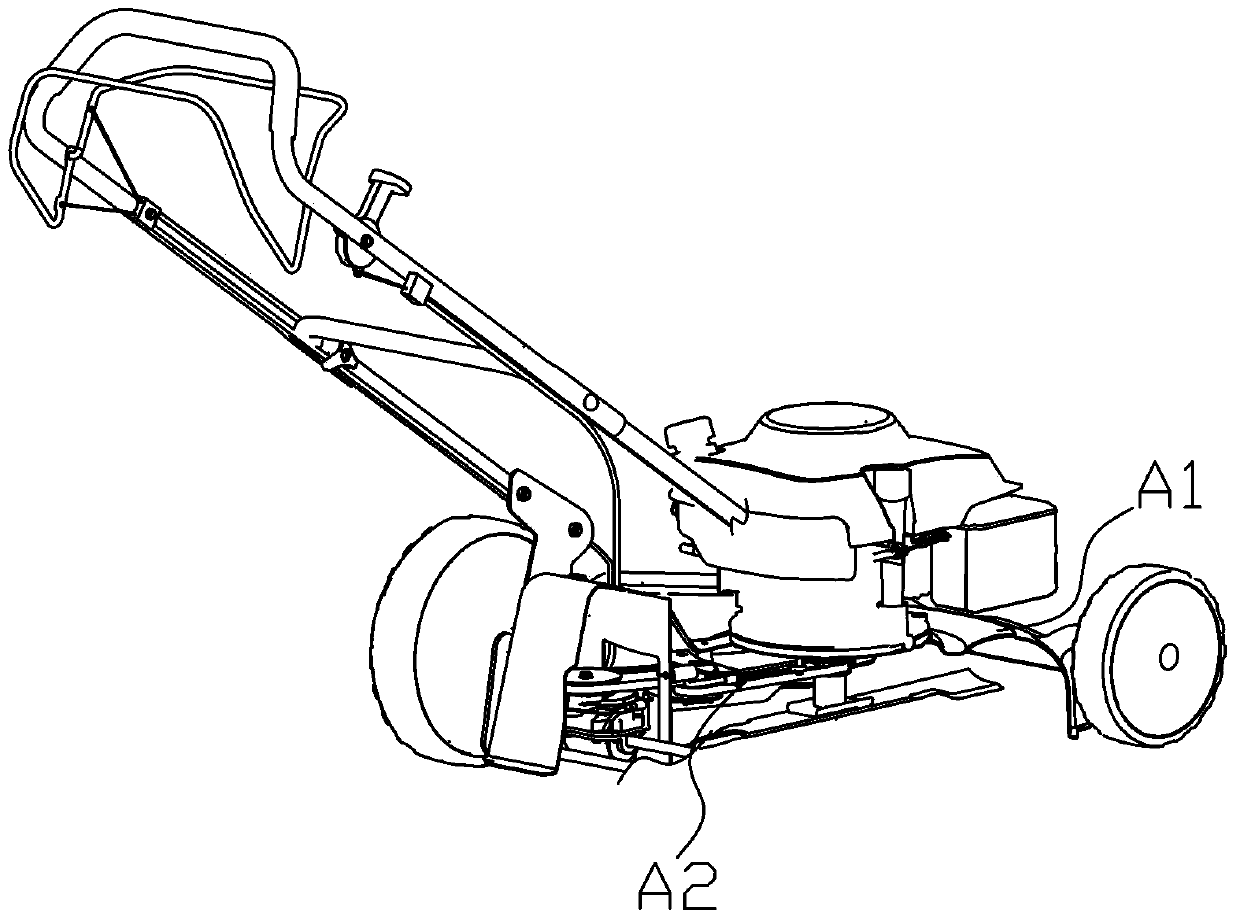

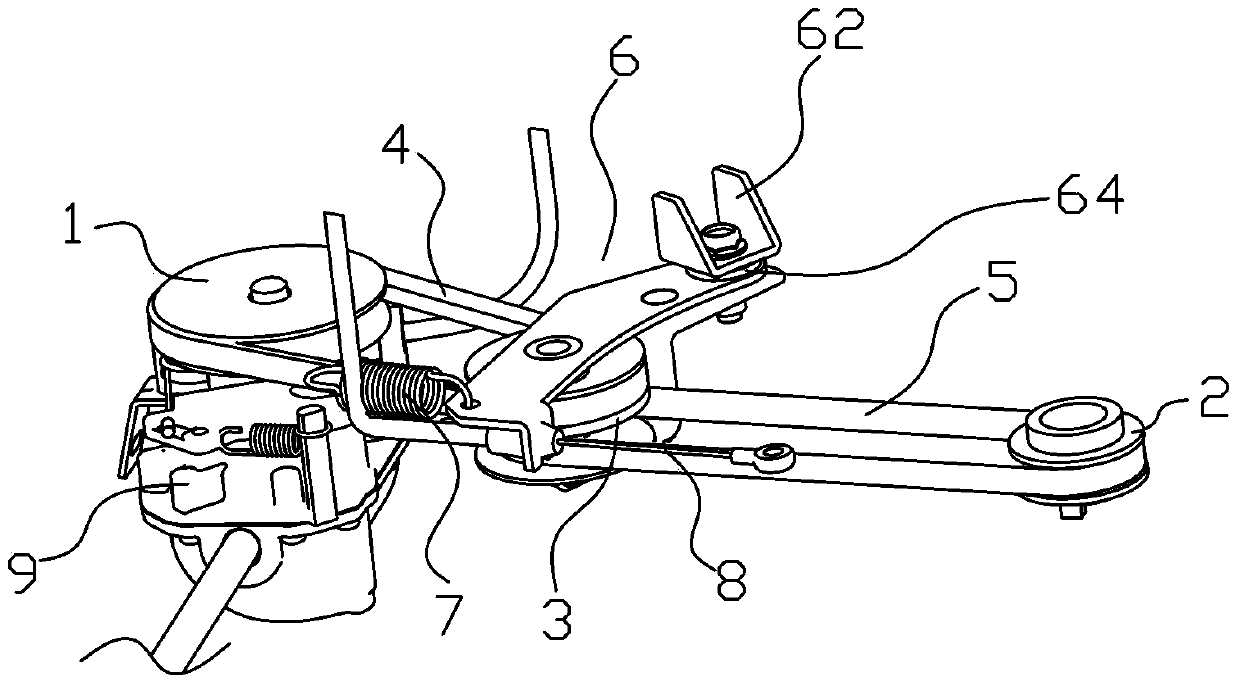

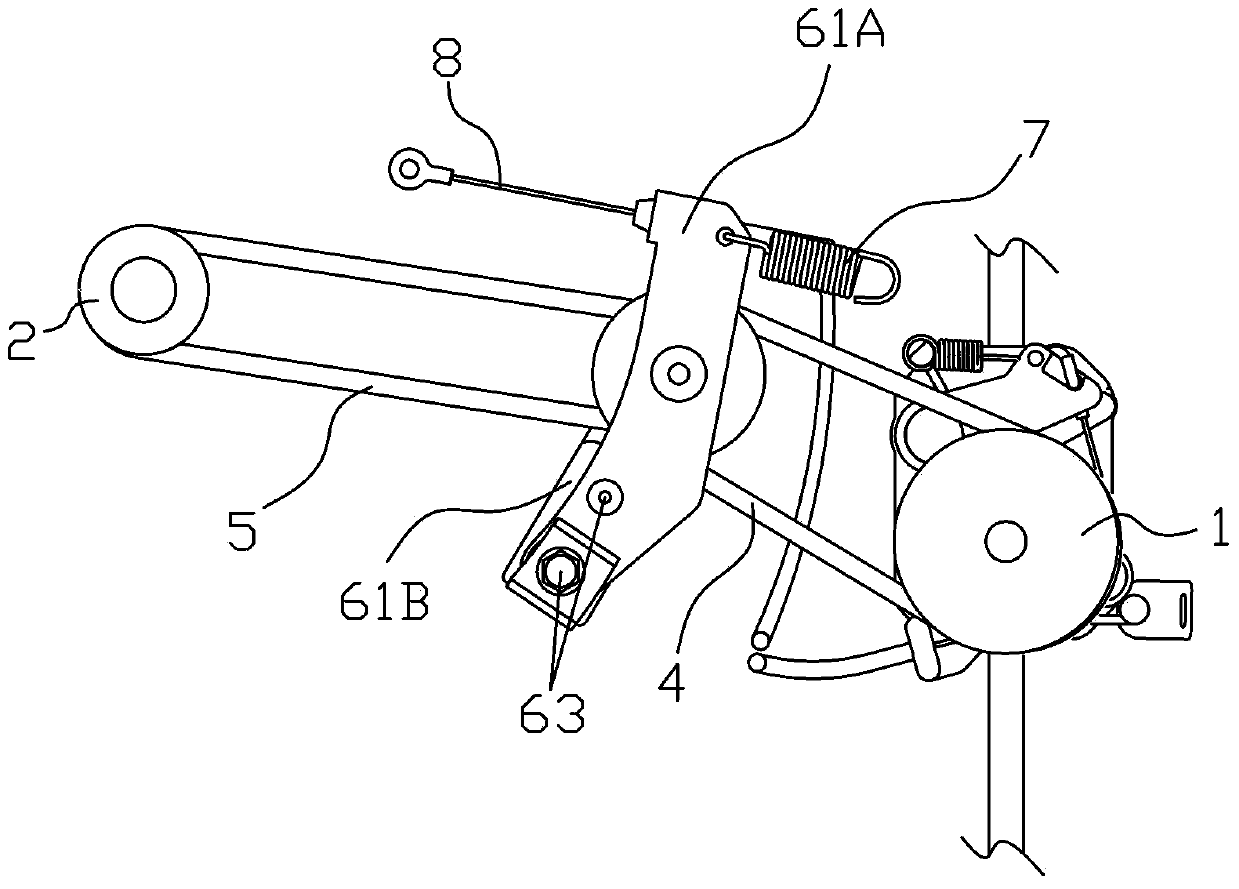

[0024] Such as figure 1 , 2 , 3, 4, 5, and 6. What the present invention discloses is a walking stepless speed change adjustment mechanism of a lawn machine. The present invention is to change the speed of the lawn machine. The specific technical scheme is as follows:

[0025] This continuously variable speed adjustment mechanism is installed in the interior of the lawn machine body A1, which includes a slave pulley 1, a main pulley 2, a variable speed pulley set 3, a first variable speed trimming belt 5 and a second variable speed trimming belt 4, so The speed change pulley set 3 includes an upper speed change pulley 31A, a lower speed change pulley 31B and a speed change main shaft 32 connecting the upper speed change pulley 31A and the lower speed change pulley 31B, located between the upper speed change pulley 31A and the lower speed change pulley 31B A speed change wheel 33 is movably installed, and the speed change wheel 33 can move up and down along the speed change ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com