Method for purifying trichlorosilane

A technology for purifying trichlorosilane and trichlorosilane, which is applied in the direction of silicon halides, halosilanes, etc., can solve the problems of low purity of trichlorosilane, many impurities in the product, and the need for improvement of trichlorosilane. Response safety, high efficiency, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

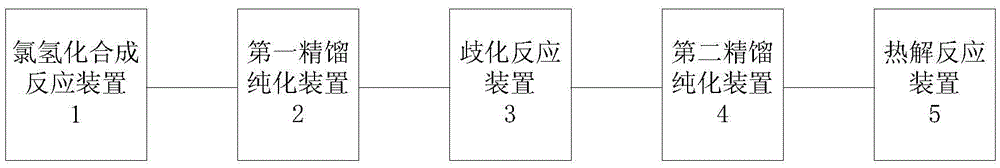

[0089] The above part has described the method for preparing polysilicon of the present invention in detail. In order to better understand the method, the equipment capable of implementing the method will be described in detail below.

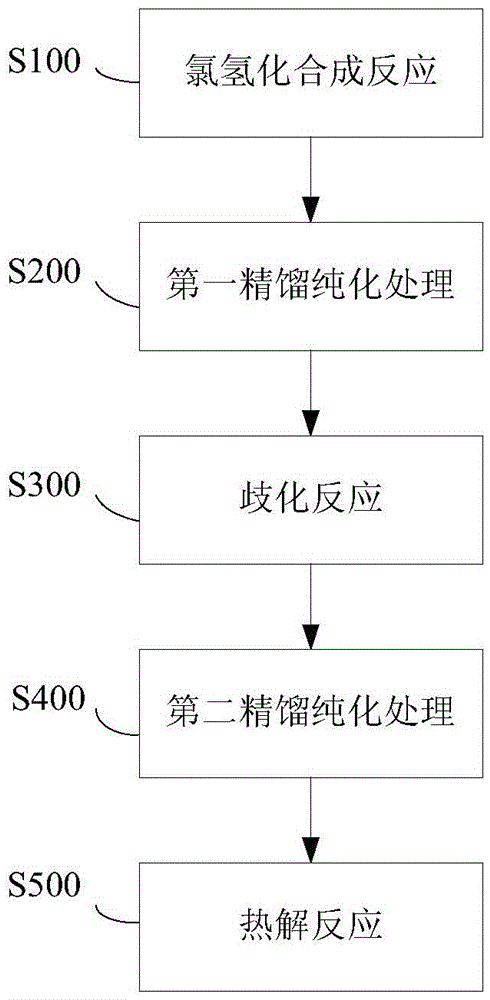

[0090] Therefore, according to another aspect of the present invention, the present invention also proposes an equipment for preparing polysilicon. According to an embodiment of the present invention, refer to image 3 , The equipment for preparing polysilicon of the present invention includes: a hydrochlorination synthesis reaction device 1 , a first rectification purification device 2 , a disproportionation reaction device 3 , a second rectification purification device 4 and a pyrolysis reaction device 5 . According to some embodiments of the present invention, the hydrochlorination synthesis reaction device 1 is used to make silicon powder, hydrogen, and at least one selected from hydrogen chloride and silicon tetrachloride undergo a hydroch...

Embodiment 1

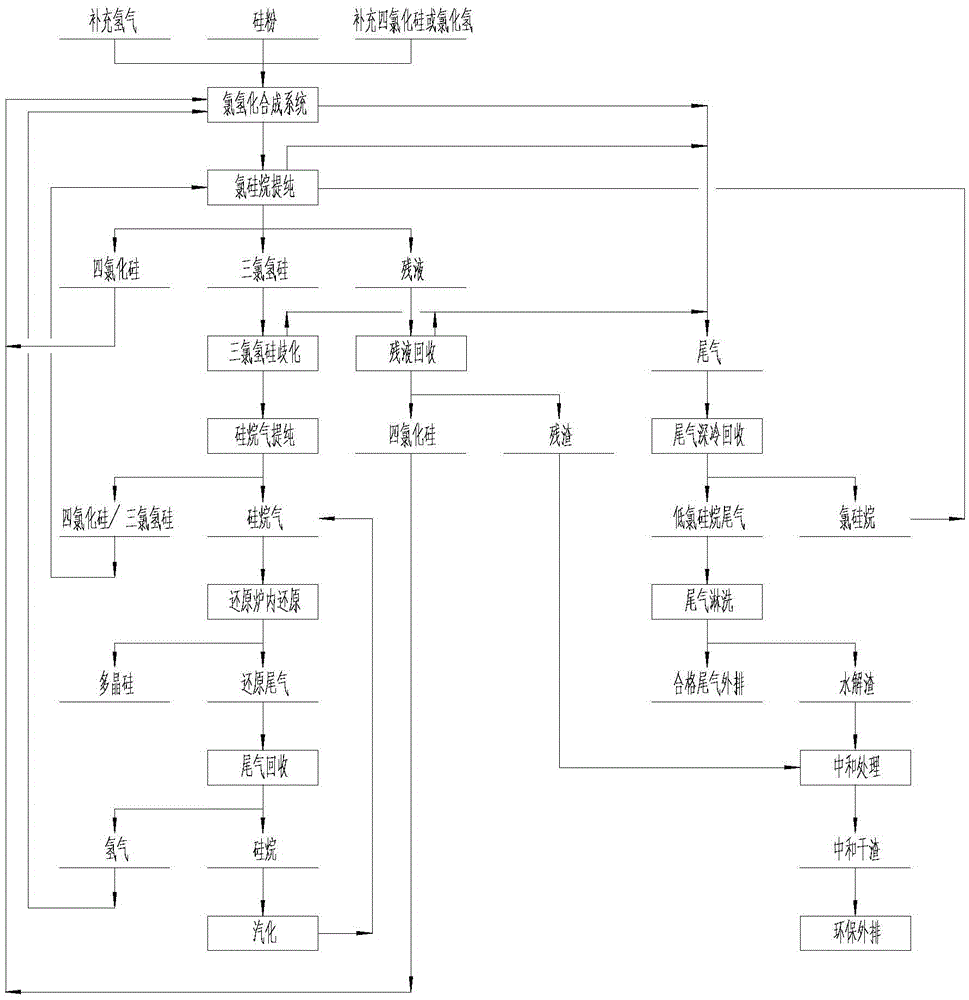

[0112] use Figure 3-Figure 11 device shown, refer to figure 1 and figure 2 According to the flow shown, according to the method for preparing polysilicon of the present invention, trichlorosilane is prepared and purified according to the following process steps, and then polysilicon is prepared:

[0113] (1) Synthesis step of hydrochlorination: Silicon tetrachloride and hydrogen from the following steps (2) and (3) are mixed in a gas-liquid mixer, then exchange heat with the hydrogenation reactor outlet gas, and enter resistance heating Heating to a certain temperature, the mixed gas directly enters the hydrogenation reactor, the temperature is controlled at 500-550 degrees, the pressure is 1.5-3.5MPa, the ratio of silicon tetrachloride to hydrogen is 1:2-1:5, nickel-based or copper-based Under the action of catalyst, it reacts with silicon powder. After the reaction gas passes through the high-efficiency gas-solid dust collector, it exchanges heat with the gas from the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com