Solvent dewaxing method of low wax content hydrocarbon oil

A dewaxing solvent and dewaxing technology, applied in the field of dewaxing of hydrocarbon oil, can solve problems such as difficulty in removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

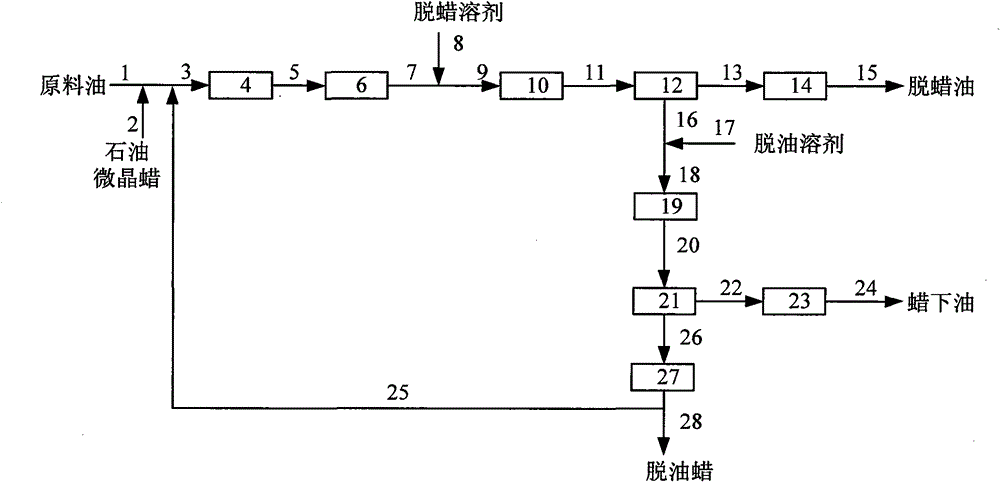

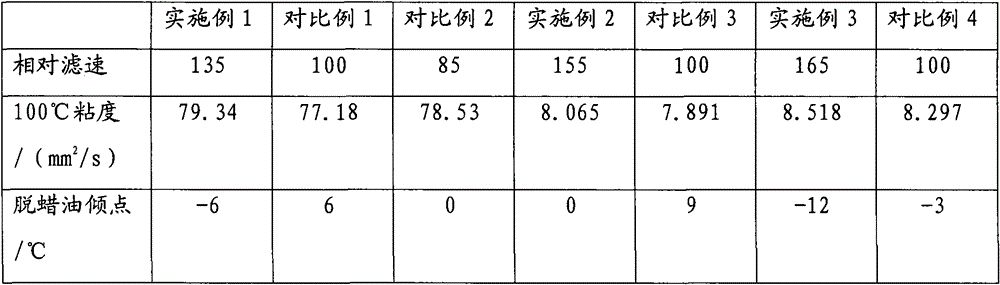

[0039] The extracted oil is used as the raw material, and its properties are shown in Table 1. The mass ratio of microcrystalline wax to raw oil is 0.12:1, the dewaxing solvent is butanone-toluene mixed solvent, the volume content of butanone is 95%, the multi-point dilution process is adopted, and the total agent-oil ratio is 2:1. The deoiling solvent is the same as the dewaxing solvent, with one dilution, and the solvent-to-oil ratio is 0.7:1 (relative to the raw material oil). Attachedfigure 1 The flow process preparation dewaxed oil, concrete process is as follows:

[0040] (1) Add petroleum microcrystalline wax with a drop melting point of 75°C to the raw material oil, heat to 80°C, fully melt and mix well, then add dilution solvents successively. Cool to -15°C, filter to obtain dewaxed filtrate and dewaxed wax paste, and obtain dewaxed oil after removing the solvent from the filtrate. Add diluting solvent to the wax paste and mix evenly, heat to 15°C, filter to obtain ...

Embodiment 2

[0047] The raw material is hydrotreated oil, whose properties are shown in Table 1. The mass ratio of petroleum microcrystalline wax to raw oil is 0.06:1, the dewaxing solvent is butanone-toluene mixed solvent, the volume content of butanone is 50%, and the multi-point dilution process is adopted, and the total agent-oil ratio is 6:1. The deoiling solvent is the same as the dewaxing solvent, with one dilution, and the solvent-to-oil ratio is 1.5:1 (relative to the raw material oil). Attached figure 1 The flow process preparation dewaxed oil, concrete process is as follows:

[0048] (1) Add petroleum microcrystalline wax with a drop melting point of 80°C to the raw material oil, heat to 90°C, fully melt and mix evenly, then add dilution solvents successively. Cool to -10°C, filter to obtain a dewaxed filtrate and a dewaxed wax paste, and obtain a dewaxed oil after removing the solvent from the filtrate. Add diluting solvent to the wax paste and mix evenly, heat to 30°C, filt...

Embodiment 3

[0053] Trifurfural-reduced refined oil is used as raw material, and its properties are shown in Table 1. The mass ratio of petroleum microcrystalline wax to raw oil is 0.01:1, the dewaxing solvent is butanone-toluene mixed solvent, the volume content of butanone is 70%, and the multi-point dilution process is adopted, and the total agent-oil ratio is 4:1. The deoiling solvent is the same as the dewaxing solvent, with one dilution, and the solvent-to-oil ratio is 0.3:1 (relative to the raw material oil). Attached figure 1 The flow process preparation dewaxed oil, concrete process is as follows:

[0054] (1) Add petroleum microcrystalline wax with a drop melting point of 84°C to the raw material oil, heat to 100°C, fully melt and mix evenly, then add dilution solvents successively. Cool to -20°C, filter to obtain dewaxed filtrate and dewaxed wax paste, and obtain dewaxed oil after removing solvent from the filtrate. Add diluting solvent to the wax paste and mix evenly, heat t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

| drop melting point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com