Solvent dewaxing method of low-wax content hydrocarbon oil

A dewaxing solvent and dewaxing technology, which is applied in the field of hydrocarbon oil dewaxing, can solve the problems of difficult removal, achieve the effect of increasing the frequency of warm washing, increasing the filtration speed, and reducing the temperature difference of dewaxing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

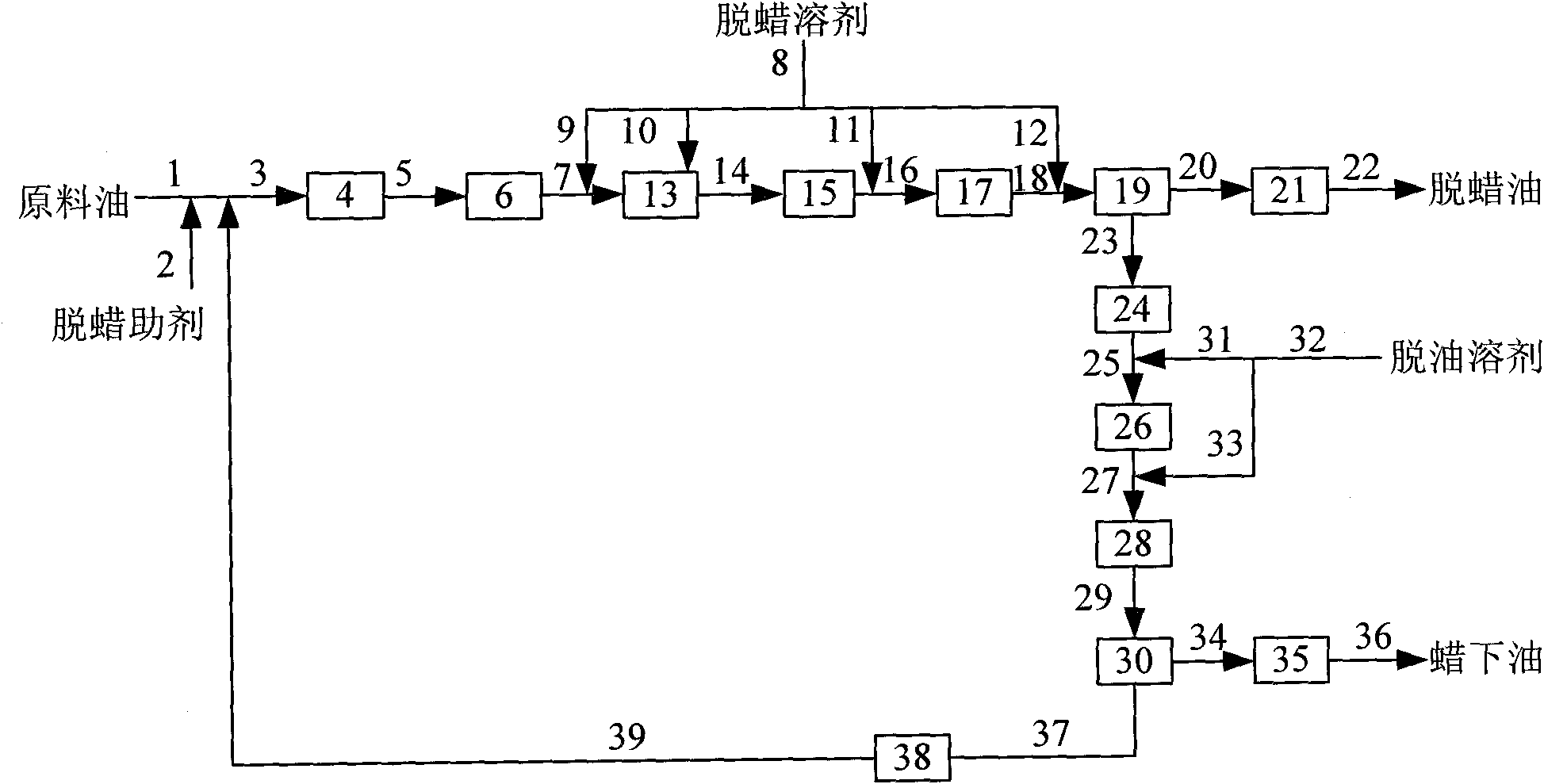

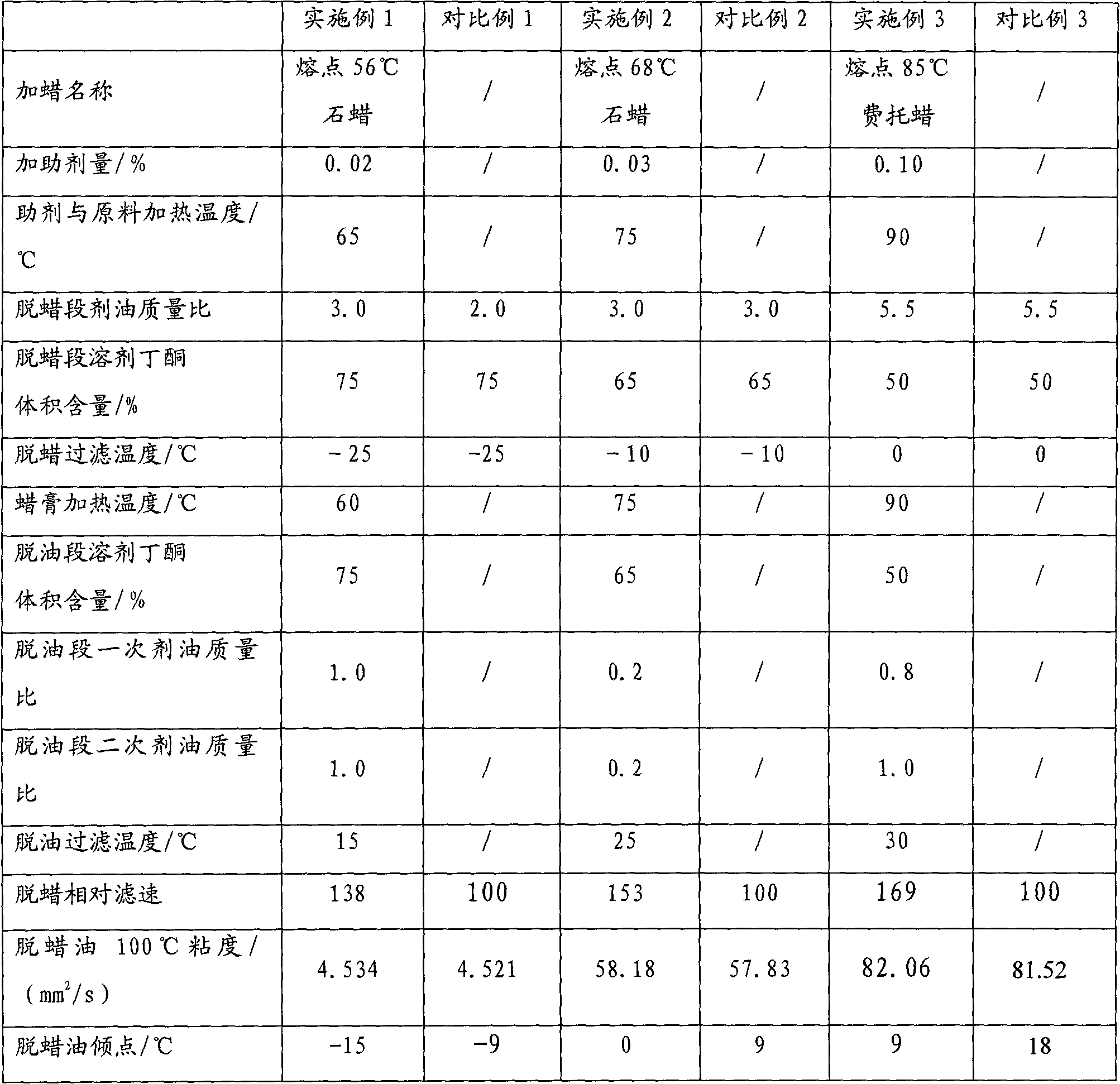

[0039] The raw material oil is refined oil with reduced second-line furfural, and its properties are shown in Table 1. The mass ratio of dewaxing aid to raw oil is 0.02:1, the dewaxing solvent is butanone-toluene mixed solvent, the volume content of butanone is 65%, and the multi-point dilution process is adopted, and the dewaxing is carried out in three casing crystallizers Crystallization at moderate cooling, dewaxing with a total agent-to-oil ratio of 3:1. The dewaxing wax paste is heated to 60°C to melt, and then a diluting solvent is added, cooled and crystallized in the first deoiling sleeve crystallizer, and then the second deoiling diluting solvent is added, and then enters the second deoiling sleeve crystallizer for crystallization. The deoiling solvent is the same as the dewaxing solvent, the primary and secondary solvent ratios for deoiling are 1:1 and 1:1 respectively, and the total agent-oil ratio for deoiling is 2:1 (relative to the raw material oil). Attached ...

Embodiment 2

[0044] The raw material oil is extracted oil with four-line furfural reduction, and its properties are shown in Table 1. The mass ratio of dewaxing aid to raw oil is 0.03:1, the dewaxing solvent is butanone-toluene mixed solvent, the volume content of butanone is 75%, and the multi-point dilution process is adopted, and the dewaxing is carried out in three casing crystallizers Crystallization at moderate cooling, dewaxing with a total agent-to-oil ratio of 2:1. The dewaxing wax paste is heated to 75°C to melt, then a diluting solvent is added, cooled and crystallized in the first deoiling sleeve crystallizer, and then the second deoiling diluting solvent is added, and then enters the second deoiling sleeve crystallizer for crystallization. The deoiling solvent is the same as the dewaxing solvent, the primary and secondary solvent ratios for deoiling are 0.2:1 and 0.2:1 respectively, and the total agent-oil ratio for deoiling is 0.4:1 (relative to the raw material oil). Attach...

Embodiment 3

[0049] The raw oil is lightly desolvated and refined extracted oil, and its properties are shown in Table 1. The mass ratio of dewaxing aid to raw oil is 0.1:1, the dewaxing solvent is butanone-toluene mixed solvent, the volume content of butanone is 50%, and the multi-point dilution process is adopted, and the dewaxing is carried out in three casing crystallizers Crystallization at moderate cooling, the total agent-to-oil ratio is 5.5:1. The dewaxing wax paste is heated to 90°C to melt, and then a diluting solvent is added, cooled and crystallized in the first deoiling sleeve crystallizer, and then the second deoiling diluting solvent is added, and then enters the second deoiling sleeve crystallizer for crystallization. The deoiling solvent is the same as the dewaxing solvent, the ratios of primary and secondary solvents for deoiling are 0.8:1 and 1:1 respectively, and the total agent-oil ratio for deoiling is 1.8:1 (relative to the raw material oil). Attached figure 1 The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com