Textile sample weaving machine with seam quilting function

A small prototype, functional technology, applied in textiles, looms, multi-looms, etc., can solve problems such as single function, simple structure, and incompetence of fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

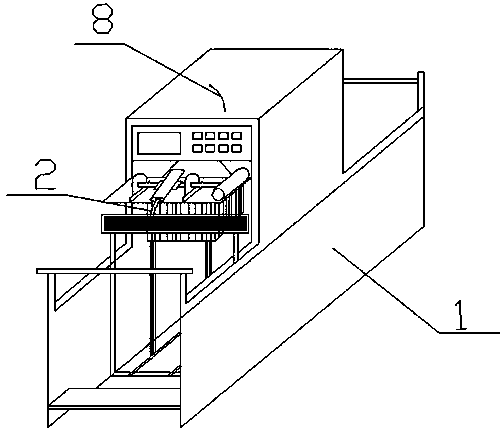

[0016] As shown in Figure 1, the textile sample machine with quilting function includes textile proofing machine 1 and pick needle 2. Picking needle 2 is fixed on the top of textile proofing machine 1, and the needle hook of picking needle 2 is facing the sample cloth woven on textile proofing machine 1. An arc-shaped spring tension adjustment piece 8 is fixed on the upper side of the spinning proofing machine to prevent instant relaxation and tension caused by uneven spinning speed.

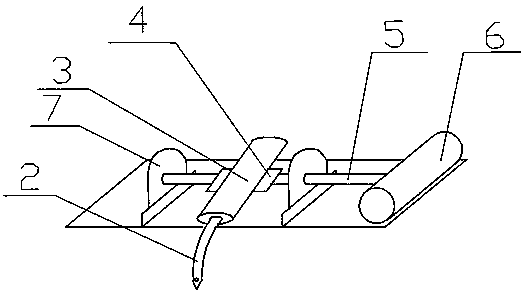

[0017] As shown in Figure 2, the yarn picking needle 2 is fixed on the piston of the cylinder 3, and the cylinder 3 moves the yarn picking needle 2 up and down by charging and deflated. The cylinder 3 is fixedly connected to the screw seat 4, and there is a round hole in the middle of the screw seat 4, and a thread is provided in the round hole, and the screw seat 4 is sleeved on the screw rod 5, and the screw rod 5 is provided with a screw thread in the hole of the screw seat 4. matching threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com