Bridge expansion joint trussed beam box

A technology of expansion joints and truss beams, which is applied to bridges, bridge parts, bridge construction, etc., can solve the problems of high steel bar density, emptying of the support box of the expansion device, and low concrete slump, so as to reduce the cost of the service life and durability Improve stability and avoid the effect of empty force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

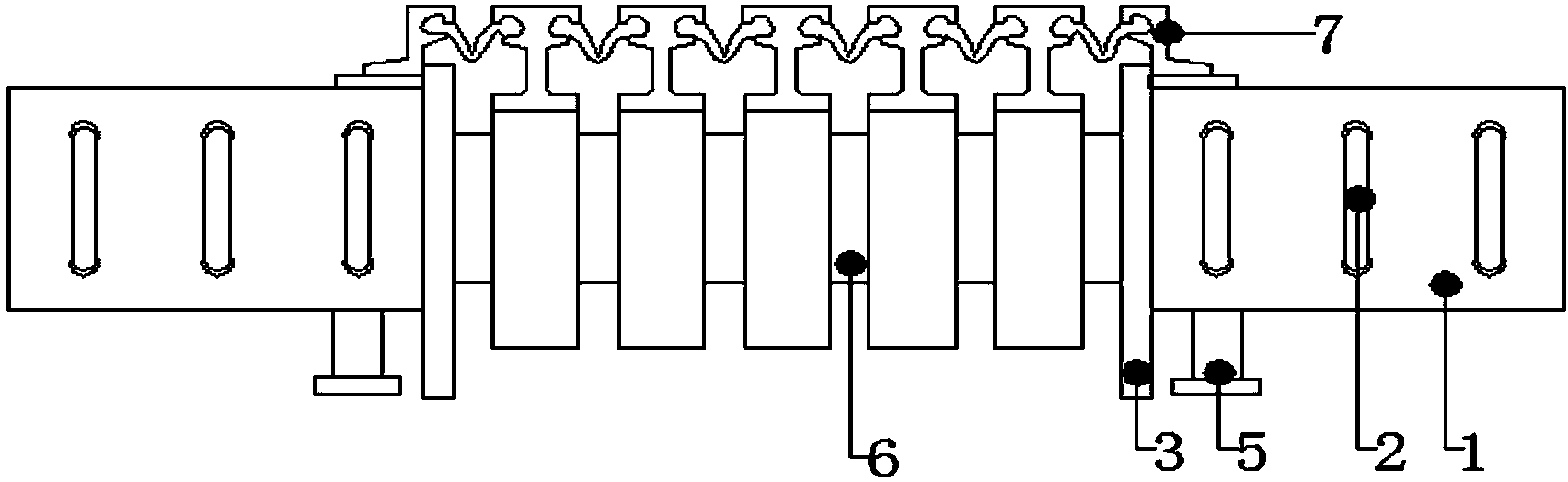

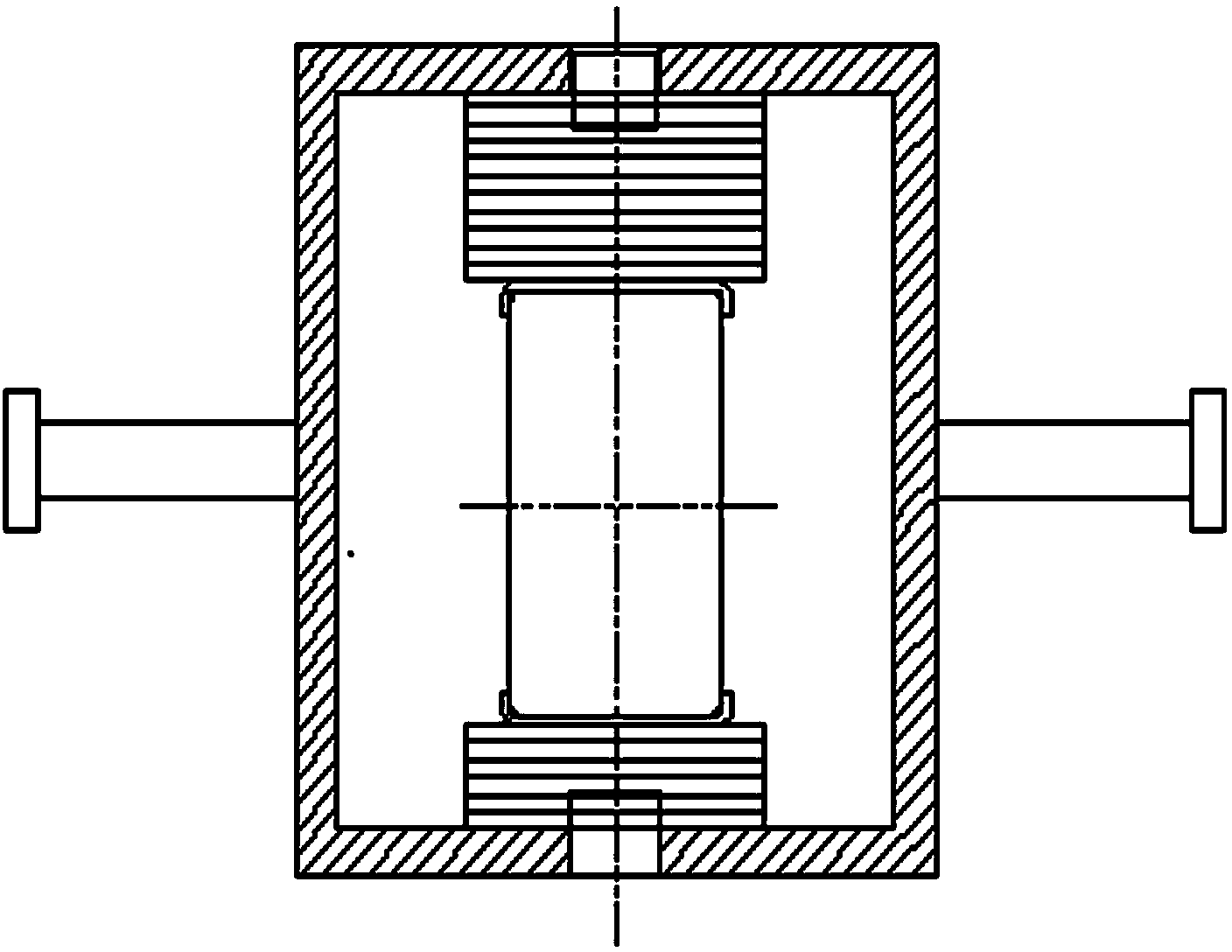

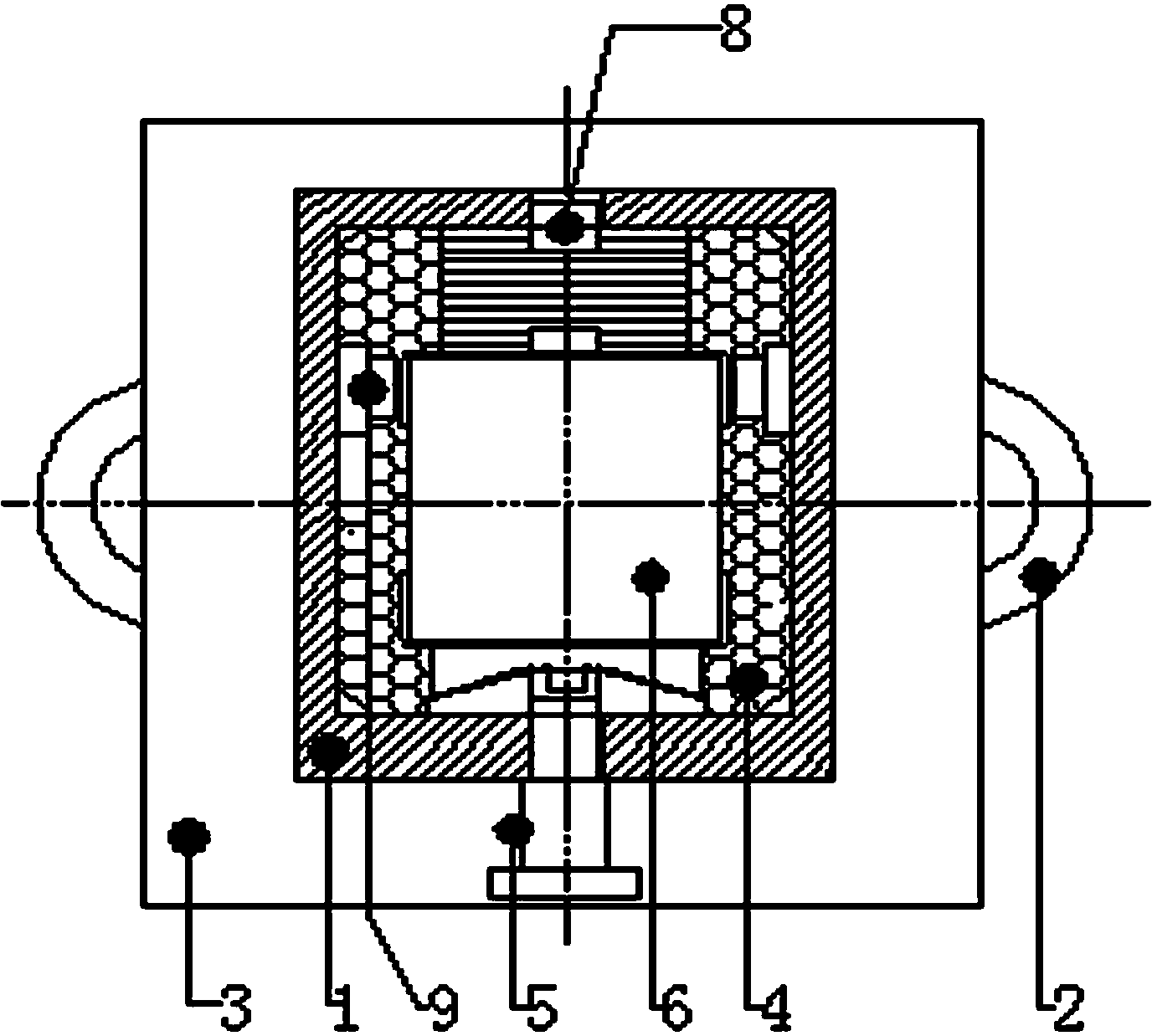

[0020] Such as Figure 1 to Figure 3 As shown, the bridge expansion joint truss box disclosed by the present invention comprises a cuboid truss box 1 located on both sides of the side beam 7, the longitudinal side wall of the truss box 1 has an annular anchor bar 2, and the inner end surface has a Reinforced coaming 3, the surroundings of the reinforced coaming 3 all protrude from the outer edge of the end face, and holes of corresponding shapes are arranged at the inner cavity corresponding to the inner end face, for the girder 6 to pass through. There are multiple groups of annular anchor bars 2 on the longitudinal side walls of the supporting box 1, and the two ends of the annular anchor bars 2 are welded and fixed to the side walls of the truss box 1 to prevent the overall settlement of the truss box 1. The reinforced coaming 3 and the truss box body 1 are connected by welding, which can be cut from one whole steel plate or tailor-welded from several steel plates. The rei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com