Assembling type floor formwork system with preset suspension reinforcing steel bars

A prefabricated and hanging technology, applied in the direction of formwork/formwork/work frame, construction components on-site preparation, structural elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

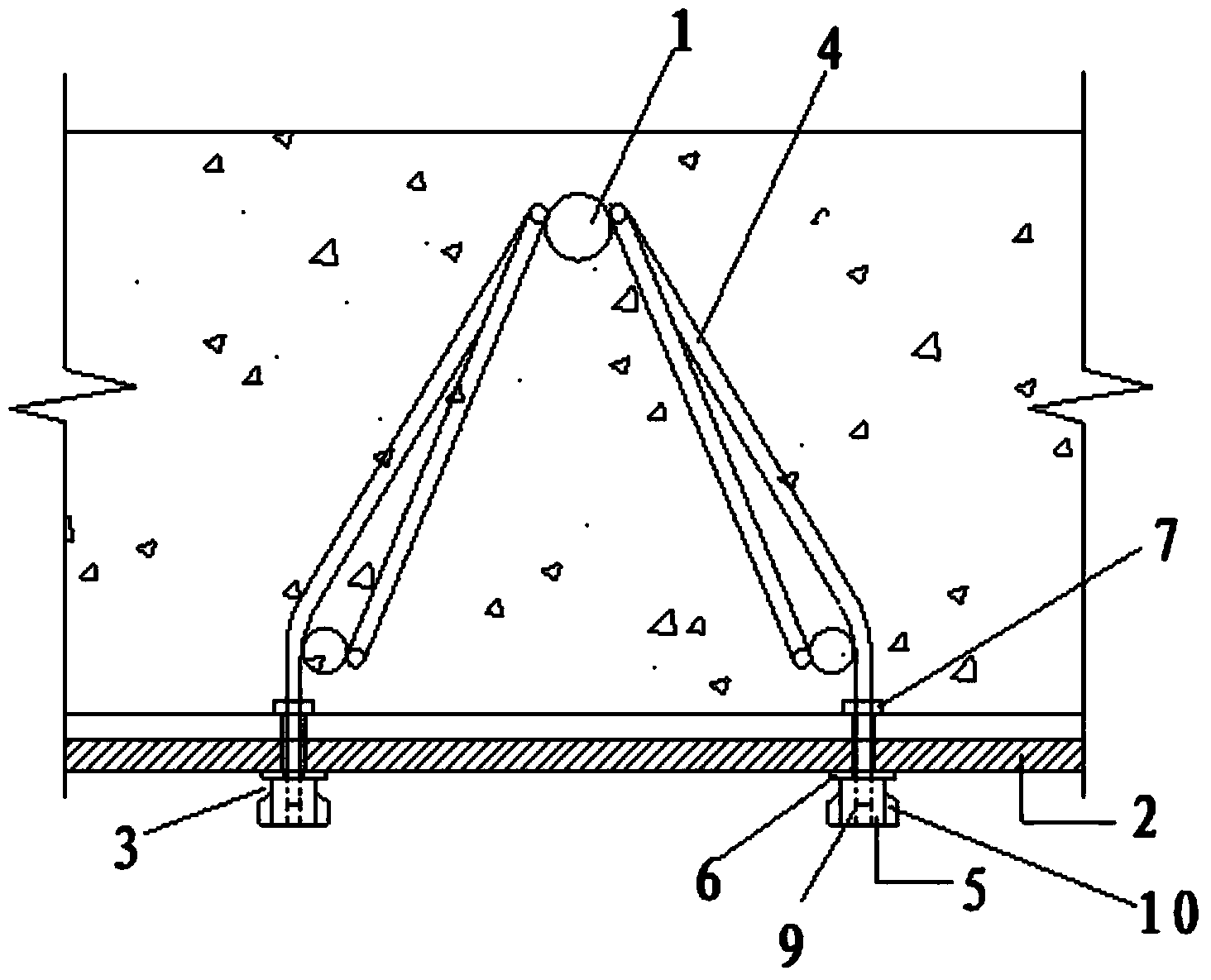

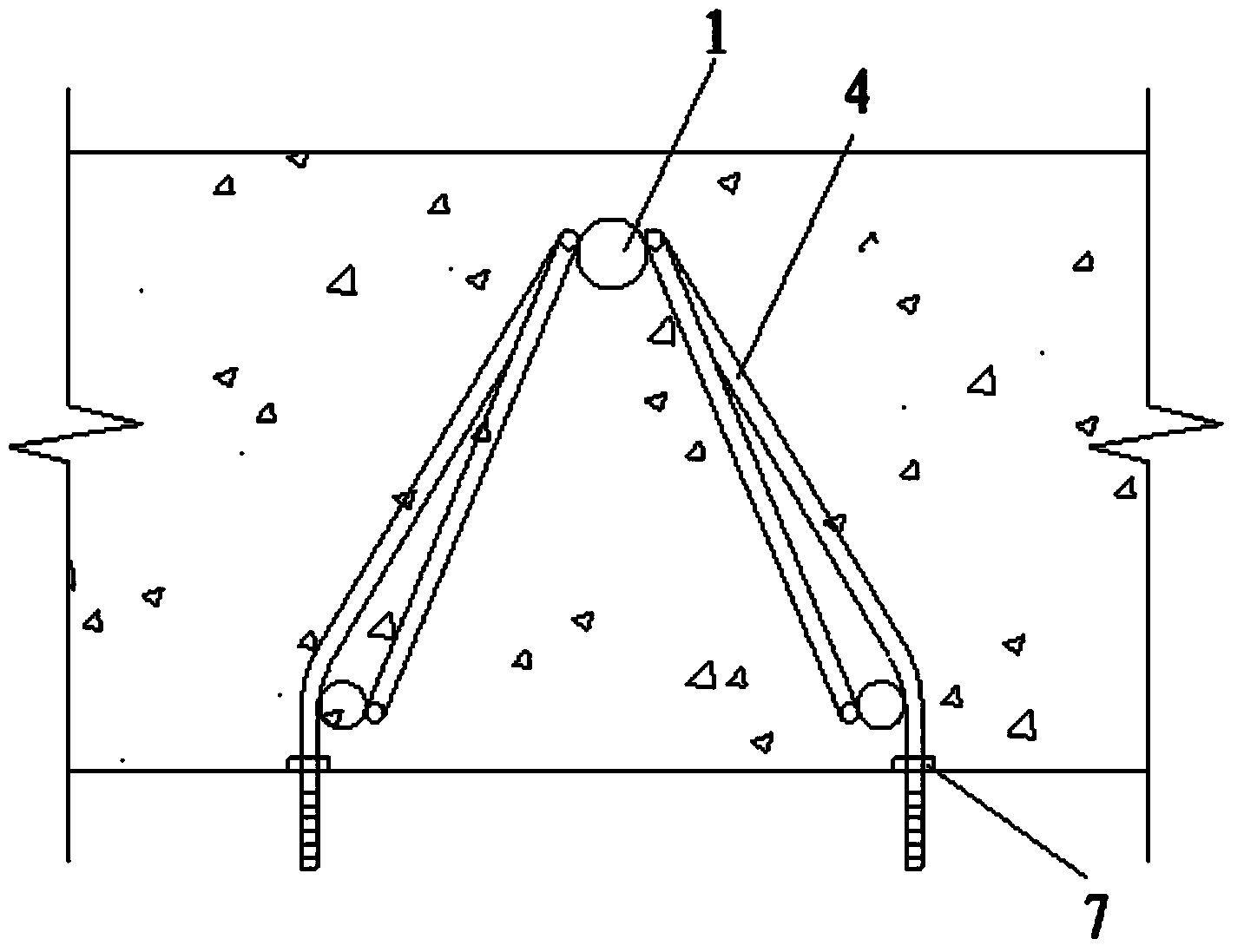

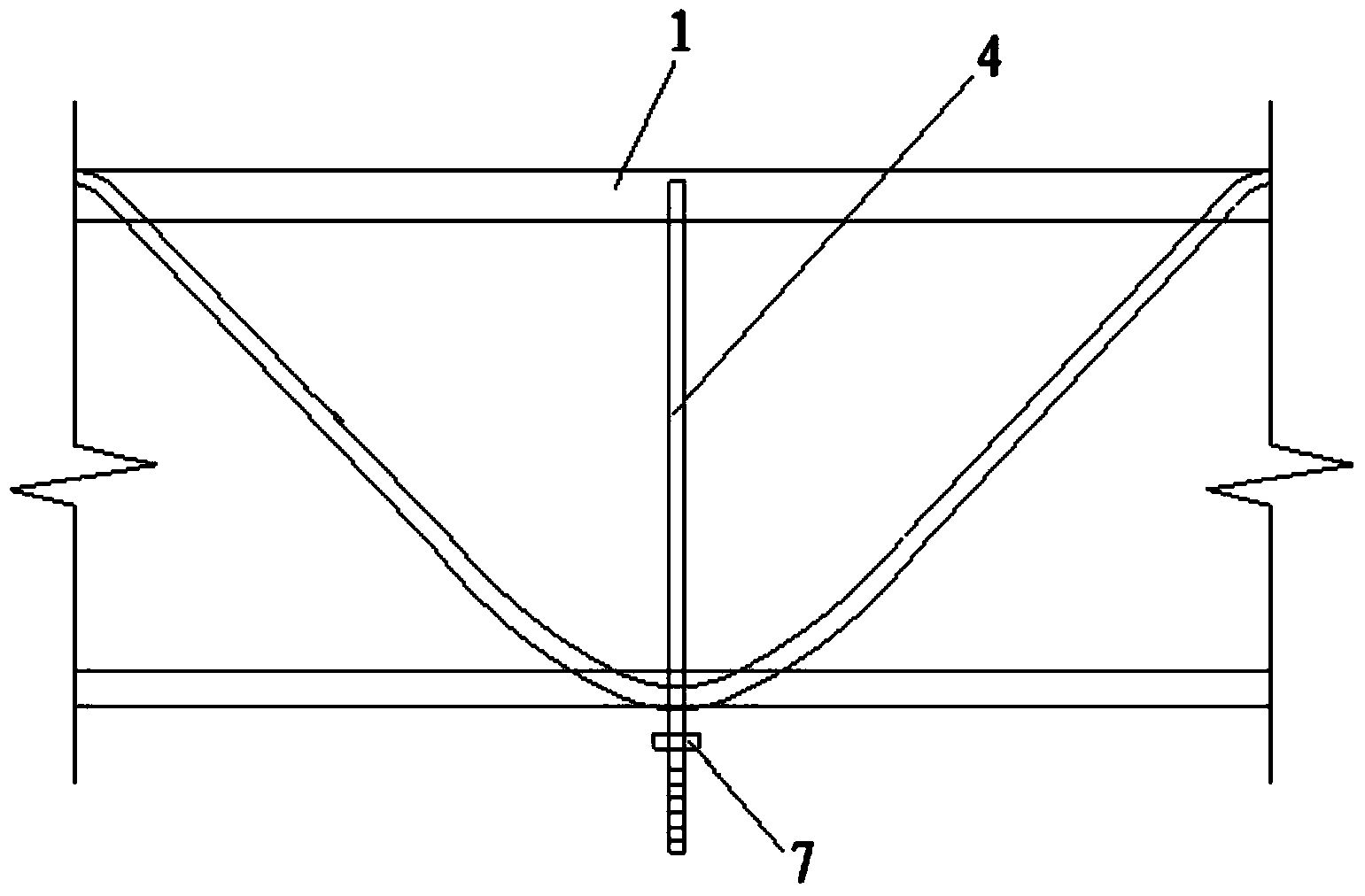

[0031] like Figure 1-6 As shown, a prefabricated floor formwork system for hanging steel bars includes: a steel bar truss 1, a formwork panel 2 and a fixed connection unit 3 for connecting the steel bar truss 1 and formwork panel 2, characterized in that: The fixed connection unit 3 includes a hanging steel bar 4, a load-bearing nut 5 and a supporting gasket 6. The top end of the hanging steel bar 4 is connected to the main bar of the steel bar truss 1, and the end is provided with a thread and a limit nut 7 and The end passes through the through hole 8 on the formwork panel 2, and the support gasket 6 is tightly fixed under the formwork panel 2 with the bearing nut 5 after passing through the end of the hanging steel bar 4.

[0032] The load-bearing nut 5 includes a nut 9 and a boss 10 that is convenient for installing and removing the nut 9. The boss 10 includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com