Sectional wind power generation blade with interchangeability

A wind power generation blade, segmented technology, applied in the direction of wind power generator components, wind power generation, wind power engines, etc., can solve the problems of increased installation error, inaccurate connection positioning, poor interchangeability, etc., and achieve mold clamping equipment Cost reduction, easy assembly and disassembly, and improved interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

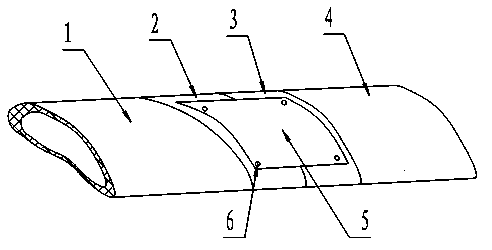

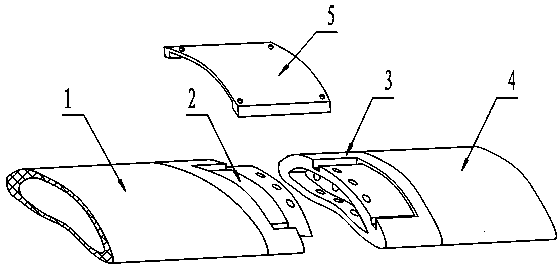

[0028] see figure 1 , figure 2 , the present invention includes a first blade segment 1, a first metal connector 2, a second metal connector 3, a second blade segment 4 and a maintenance cover 5, the first blade segment 1 and the first metal connector 2 are Integral structure, the right end of the first metal connector 2 is fitted with the left end of the second metal connector 3, the second metal connector 3 and the second blade section 4 are in an integrated structure, and the first metal connector 2 The maintenance cover 5 is installed at the assembly position of the second metal connector 3, the outer surface of the maintenance cover 5 matches the aerodynamic shape of the blade, and it is connected to the first metal connector 2 and the second metal connector through connecting screws 6 3 assembly.

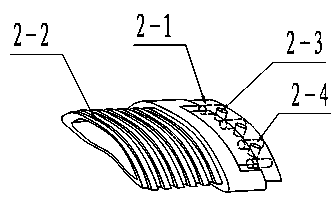

[0029] see image 3 , the outer surface of the first metal connector 2 of the present invention matches the aerodynamic shape of the blade, and the right end of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com