Built-in type point-shaped glass curtain wall ventilator

A glass curtain wall and ventilator technology, applied in ventilation system, space heating and ventilation, heating methods, etc., can solve the problems affecting the decoration effect of the curtain wall, waste of energy consumption, etc., achieve simple structure, ensure transparent effect, and scope of application wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

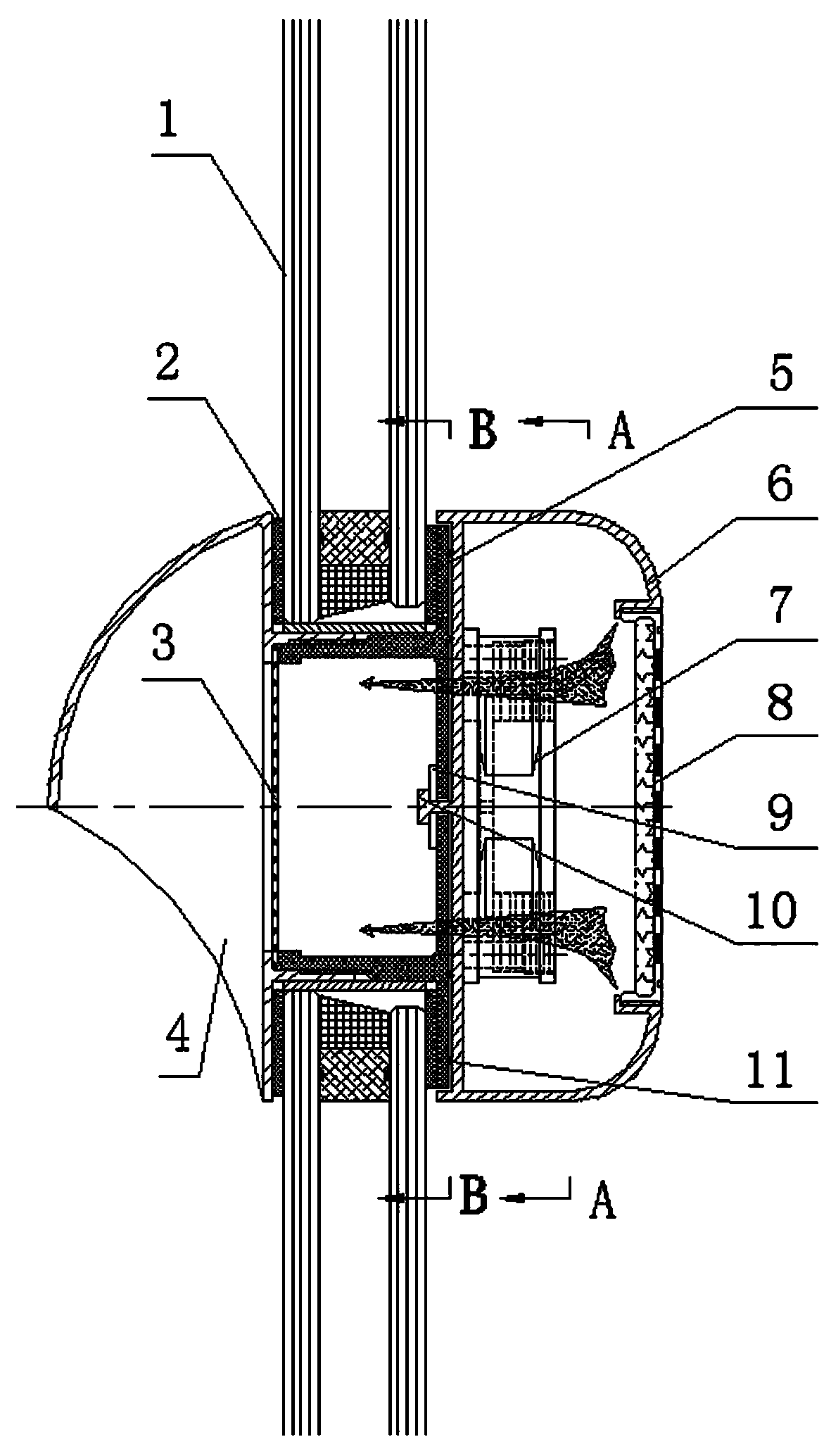

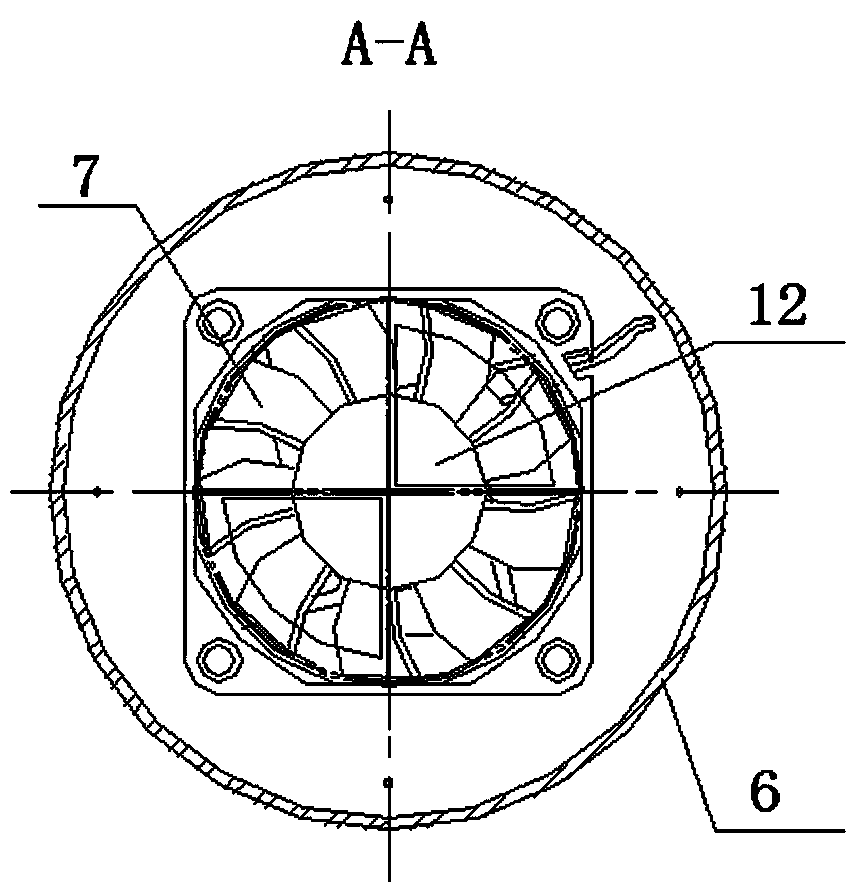

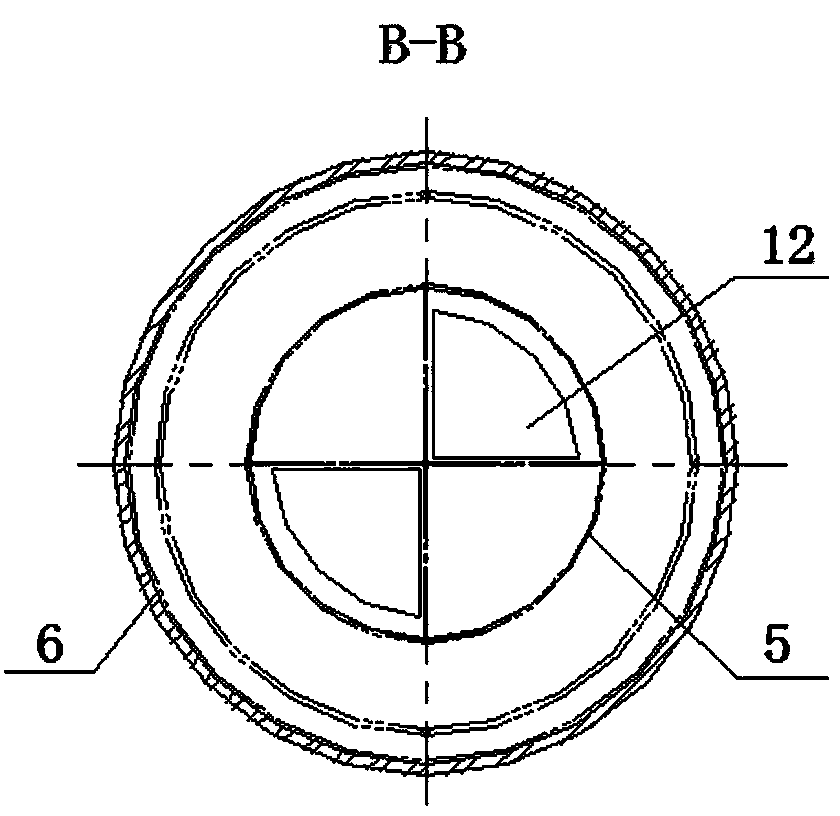

[0015] according to Figure 1~5 The specific structure of the present invention will be described in detail. The glass curtain wall built-in point ventilator includes ventilators and other parts assembled on the reserved holes of the glass surface material 1 through the sealing ring 2 and the sealing strip 11 . Wherein the ventilator is made of two parts, the outdoor flow deflector 4 and the indoor assembly. The indoor components include a sleeve 5 with offset ventilation holes 12 and strip holes 13 and a rotary ventilator. The rotary ventilator includes a housing 6 with a dislocation ventilation hole 12 and a stopper 10, an axial flow fan 7 fixed in the housing 6, and a detachable perforated ventilation cover 8 movably connected to the indoor end of the housing 6, etc. parts. The limit card seat 10 of the housing 6 passes through the bar-shaped hole 13 of the sleeve 5 and is clamped together by the circlip 9, and the end surface of the sleeve 5 with the misaligned ventilat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com