Vertical single-channel material turnover dryer

A single-channel, dryer technology, applied in the direction of dryer, drying, drying gas arrangement, etc., can solve the problems of low drying efficiency, waste of energy, affecting the full contact between hot air and materials, etc., to improve production efficiency , Improve the utilization rate and speed up the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

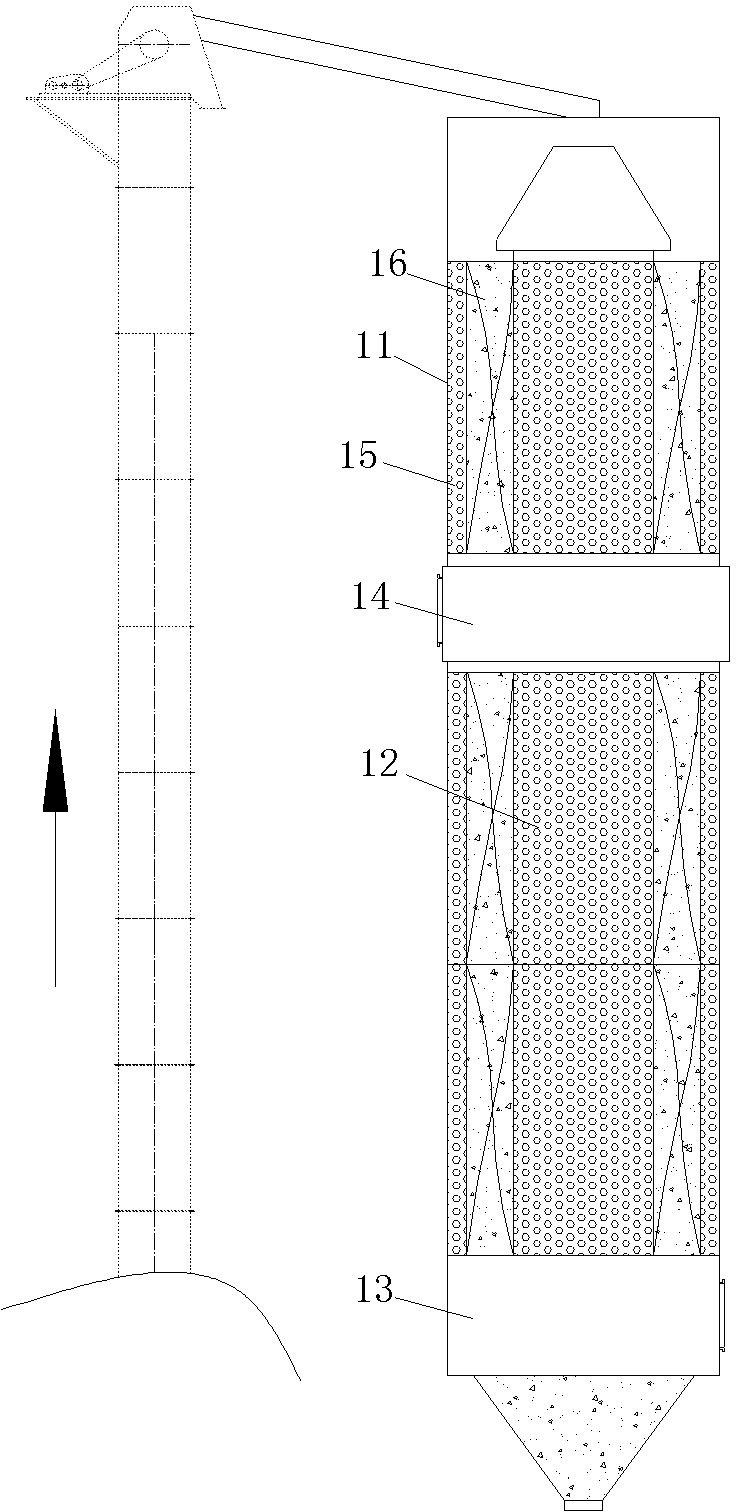

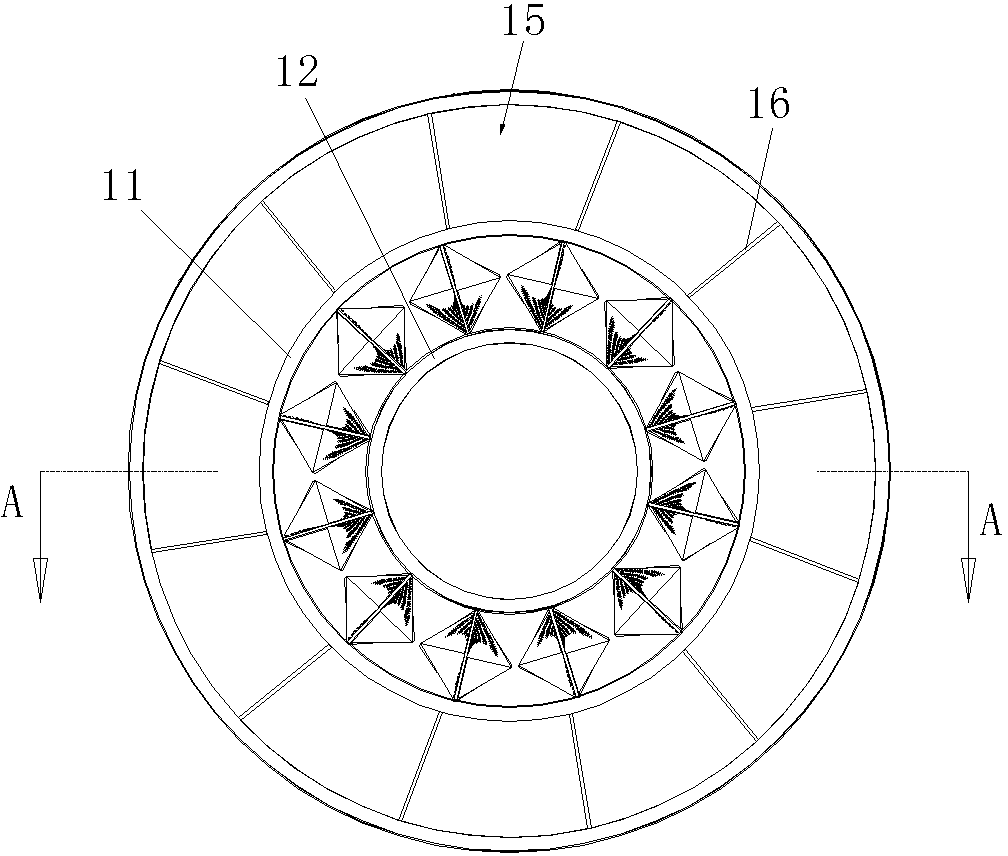

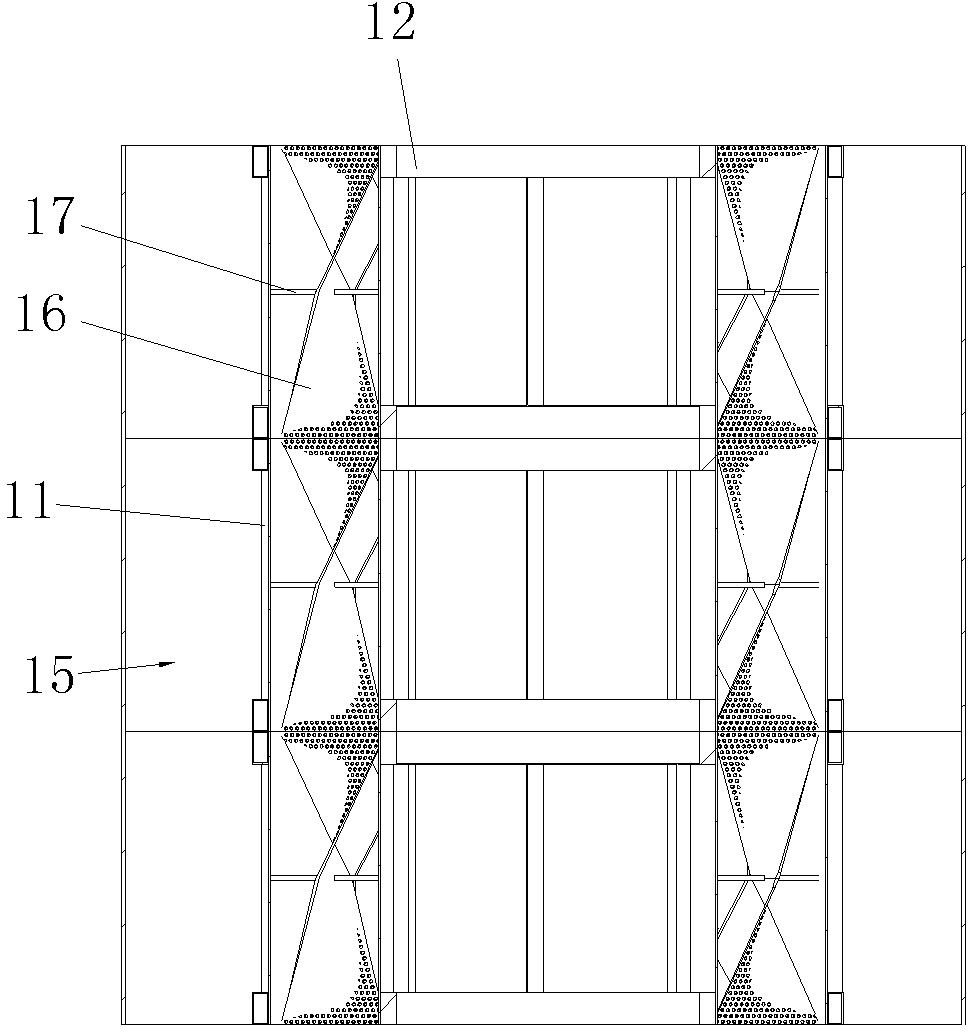

[0023] Examples of vertical single-channel material tumbling dryers, such as Figure 1-5 As shown, the vertical single-channel material tumbling dryer includes an outer cylinder 11 , an inner cylinder 12 arranged in the outer cylinder 11 , an air induction pipe 13 and an air exhaust pipe 14 arranged on the outer cylinder 11 . A material channel is formed between the outer cylinder 11 and the inner cylinder 12 . Wherein, the wall of the outer cylinder 11 is provided with a jacket-type structure, and the jacket-type structure forms a waste gas channel 15 in the wall of the outer cylinder, and the outer cylinder 11 is provided with a waste gas outlet communicating with the waste gas channel 15 ; The inner cylinder 12 is provided with an internal and external hot air inlet, and at the same time, the inner hole of the inner cylinder 12 forms a hot air channel, and the hot air inlet forms a hot air distribution port of the hot air channel. Both the air induction pipe 13 and the exh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com