Method for measuring strength of cementing materials

A technology of cementitious materials and measurement methods, which is applied in the direction of material inspection products, etc., can solve the problems such as the inability to obtain the analytical expressions of strength and influencing factors, and the inability to obtain the magnitude of the strength correlation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

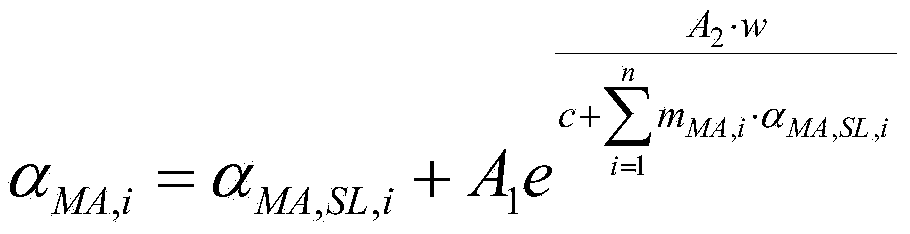

Method used

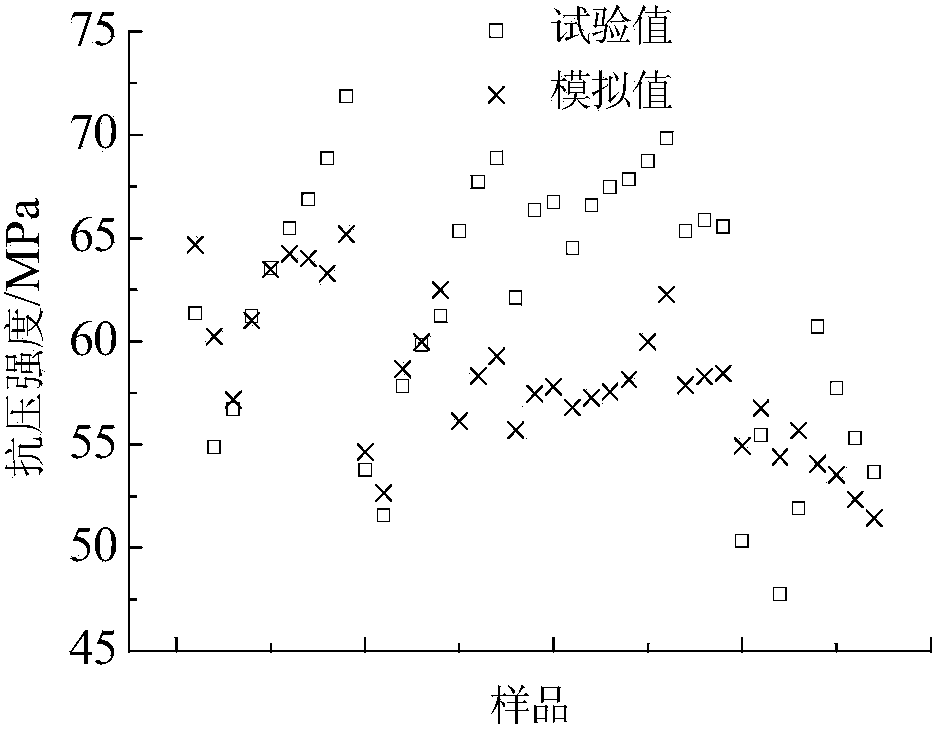

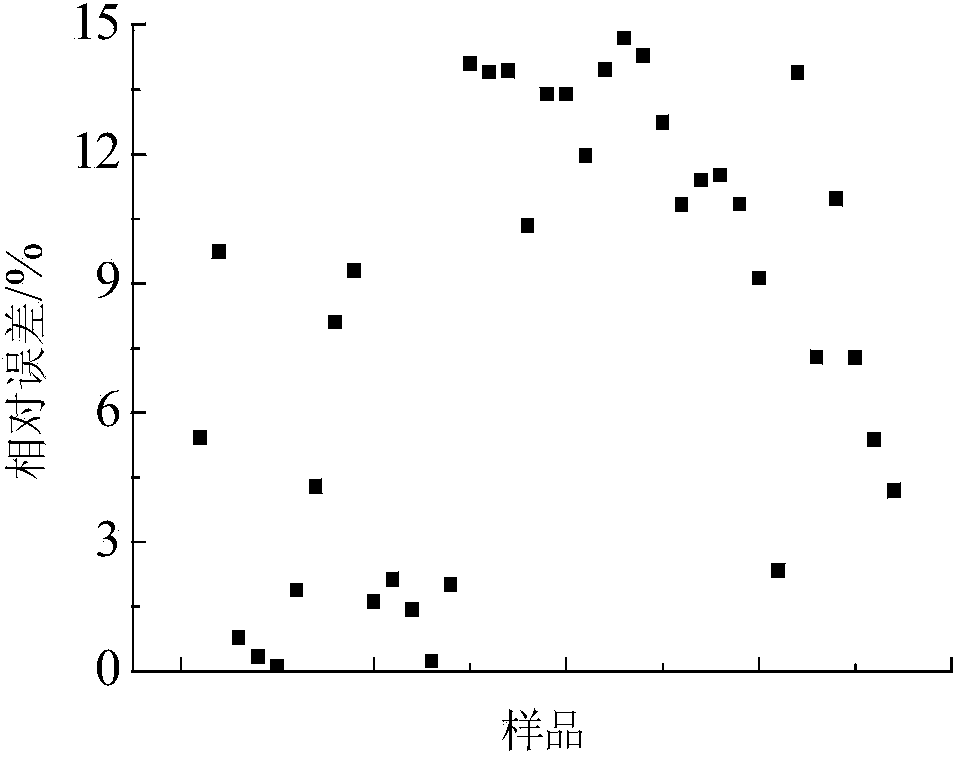

Image

Examples

Embodiment Construction

[0039] The symbols of cementitious materials are: CI is P·I52.5 grade cement produced by Jiangnan Onoda Cement Plant; CII is P·II42.5 grade cement produced by Huaxin Cement Co., Ltd.; FAI-1, FAI-2 and FAI -3 are grade I fly ash from different origins; FAII-1 and FAII-2 are grade II fly ash from different origins; BFS95-1 and BFS95-2 are S95 grade slag from different origins; S75 and S105 is S75 and S105 grade mineral powder; MK-1 and MK-2 are respectively the specific surface area of 550m 2 / kg and 1200m 2 / kg of metakaolin; LP, QP and EP are limestone powder, quartz sand powder and corundum powder with a purity greater than 90%, respectively.

[0040] 1) The apparent density of the cement and the apparent density of the mineral admixture obtained from the test are shown in Table 1.

[0041] Table 1 Cement and mineral admixture apparent density / g / cm 3

[0042]

[0043] 1) The degree of reaction of the mineral admixture in NaOH-containing saturated lime water was obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com