Retarder film and polarizing plate

A retardation film and light technology, applied in optics, optical elements, polarizing elements, etc., can solve the problem of difficulty in obtaining the balance between the retardation in the plane direction and the retardation in the thickness direction, and achieve the effect of reliable adjustment, reliable retardation, and small retardation change.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0109] Examples of the retardation film of the present invention will be described below.

[0110]In this example, the following sheet-forming material was prepared by adding 5 wt. TPP of Daihachi Chemical Industry and 5 parts by weight of #10 of Daihachi Chemical Industry. The sheet-forming material was melted and extruded through a T-die to obtain a sheet-shaped sheet-forming material, and the sheet-shaped sheet-forming material was stretched at a stretching temperature of 155° C. at a stretch ratio of 165%, The retardation film of this example was obtained. In addition, the average thickness of the retardation film was 145 μm (240 μm before stretching).

[0111] For the retardation film of the above example, the transmitted light for each wavelength was measured under the environment of 23° C. and 50% RH with an automatic birefringence measuring device (manufactured by Oji Scientific Instruments Co., Ltd., trade name: KOBRA-WR). face direction delay. The results are sho...

Embodiment approach

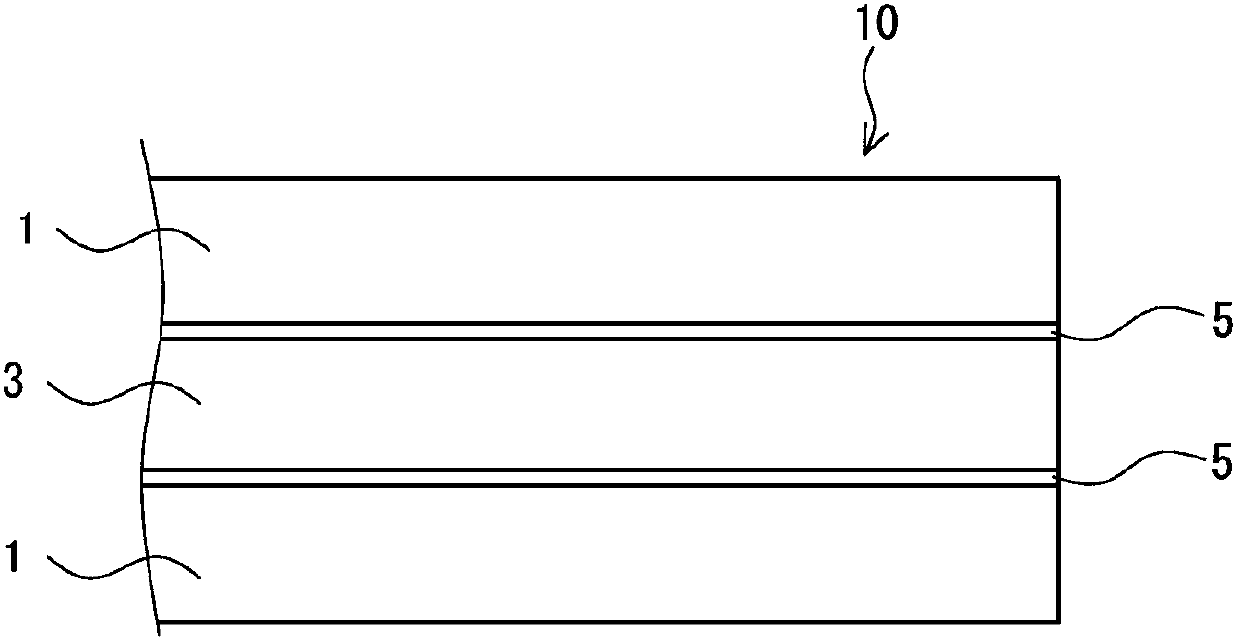

[0117] In addition, this invention is not limited to the said embodiment, Various deformation|transformation and improvement are possible. For example, the polarizing plate 10 of the above-described embodiment has been described as a polarizing plate having a three-layer structure (excluding the adhesive layer 5 ) including a pair of retardation films 1 and a polarizing plate 3 sandwiched therebetween. Change the design so that the polarizing plate 10 has, for example, a two-layer structure of the polarizer 3 and the retardation film 1. In addition, it can also be adopted on the three-layer structure of the above-mentioned embodiment. Laminated protective film structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com