Steelmaking second-stage process control system and steelmaking second-stage process control method

A technology of process control system and ladle, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc. Problems such as low management level and efficiency, to achieve the effect of convenient dispatching and unified command, improvement of overall competitiveness, and good application status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

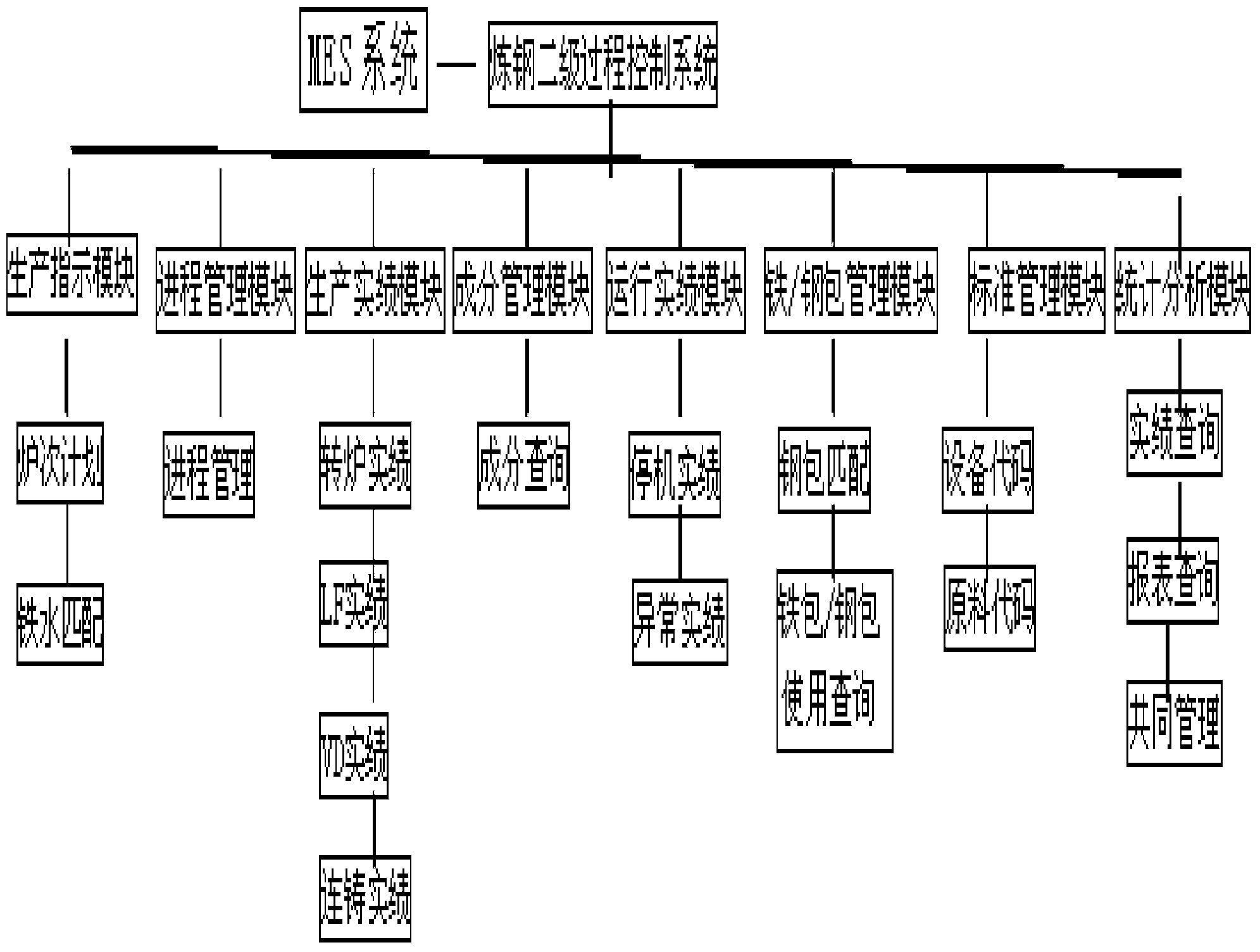

[0039] combine figure 1 , a secondary process control system for steelmaking. The system is connected to the MES system and receives the operation instructions issued by the MES system. According to the actual production performance, the molten iron plan is matched. During the production process, the converter, refining furnace, continuous casting The basic automation system obtains real-time production process data. The system includes production instruction module, process management module, production performance module, component management module, operation performance module, iron and steel ladle management module, standard management module and statistical analysis module. Under each module, multiple sub-pictures are replaced. The functions of each module are described in detail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com