Two-dimensional-image-based 3D (three-dimensional) printing system and method

A technology of 3D printing and 2D image, applied in the field of image processing, which can solve the problems of low cost, high professional skill requirements, and not supporting direct connection printing of 3D printers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

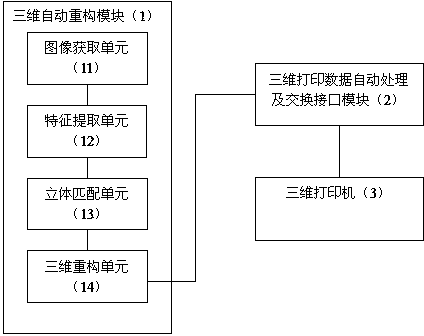

[0045] Embodiment: A three-dimensional printing system based on two-dimensional images, the principle connection diagram of the system is as follows figure 1 As shown, it includes 3D automatic reconstruction module 1, 3D printing data automatic processing and exchange interface module 2 and 3D printer 3. The 3D automatic reconstruction module is connected with the 3D printing data automatic processing and exchange interface module, and the 3D printing data is automatically processed and exchanged. The exchange interface module is connected with the three-dimensional printer. The three-dimensional automatic reconstruction module includes an image acquisition unit 11, a feature extraction unit 12, a stereo matching unit 13 and a three-dimensional reconstruction unit 14, the image acquisition unit is connected with the feature extraction unit, the feature extraction unit is connected with the stereo matching unit, and the stereo matching unit Connect with the 3D reconstruction un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com