Semi-closed space 3D printer

A 3D printer and 3D printing technology, used in the petroleum industry, processing drive devices, additives, etc., can solve the problems of low printing accuracy, poor stability of 3D printers, difficult to move, etc., to improve lubrication effect, improve service life, and reduce shaking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

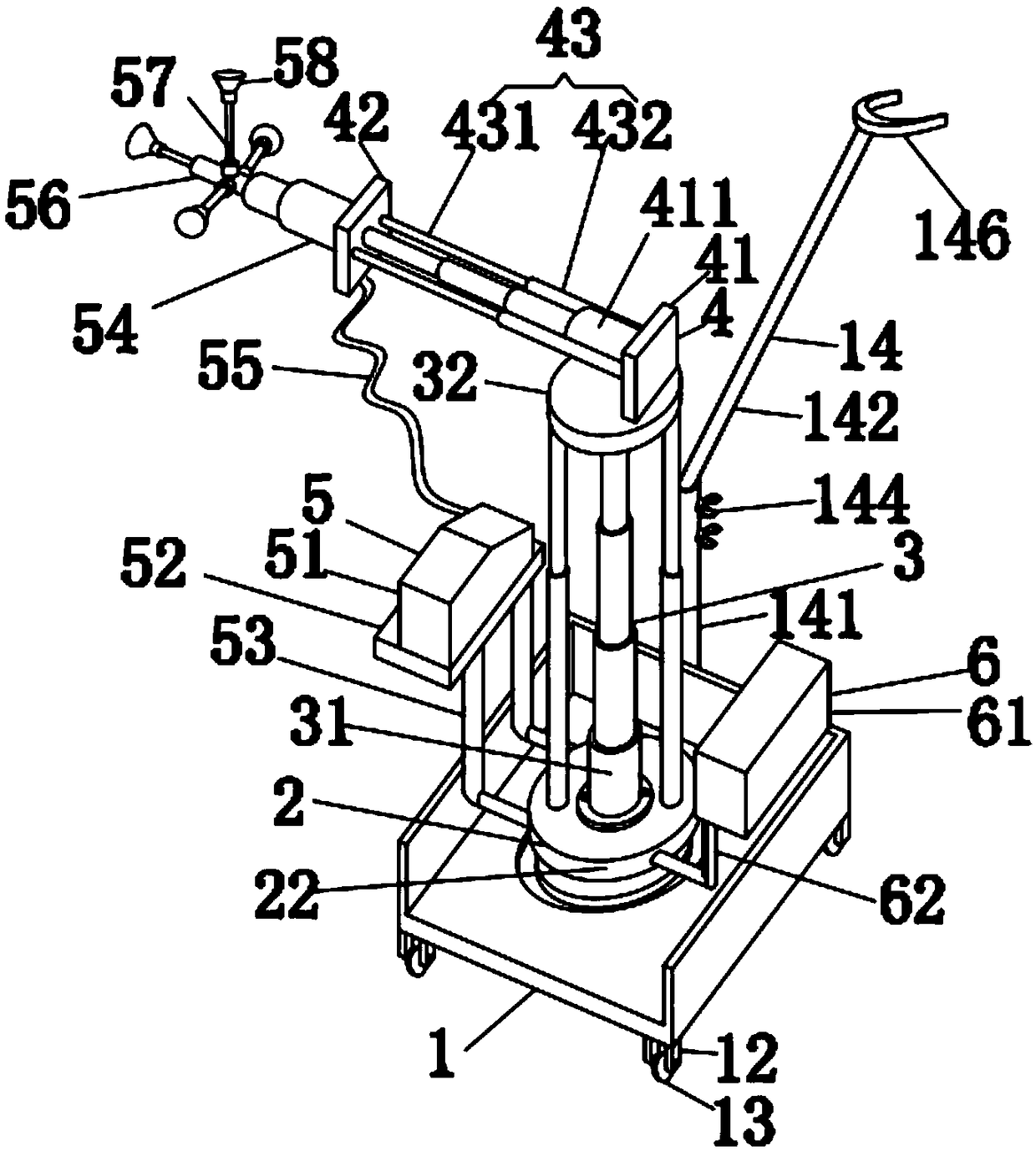

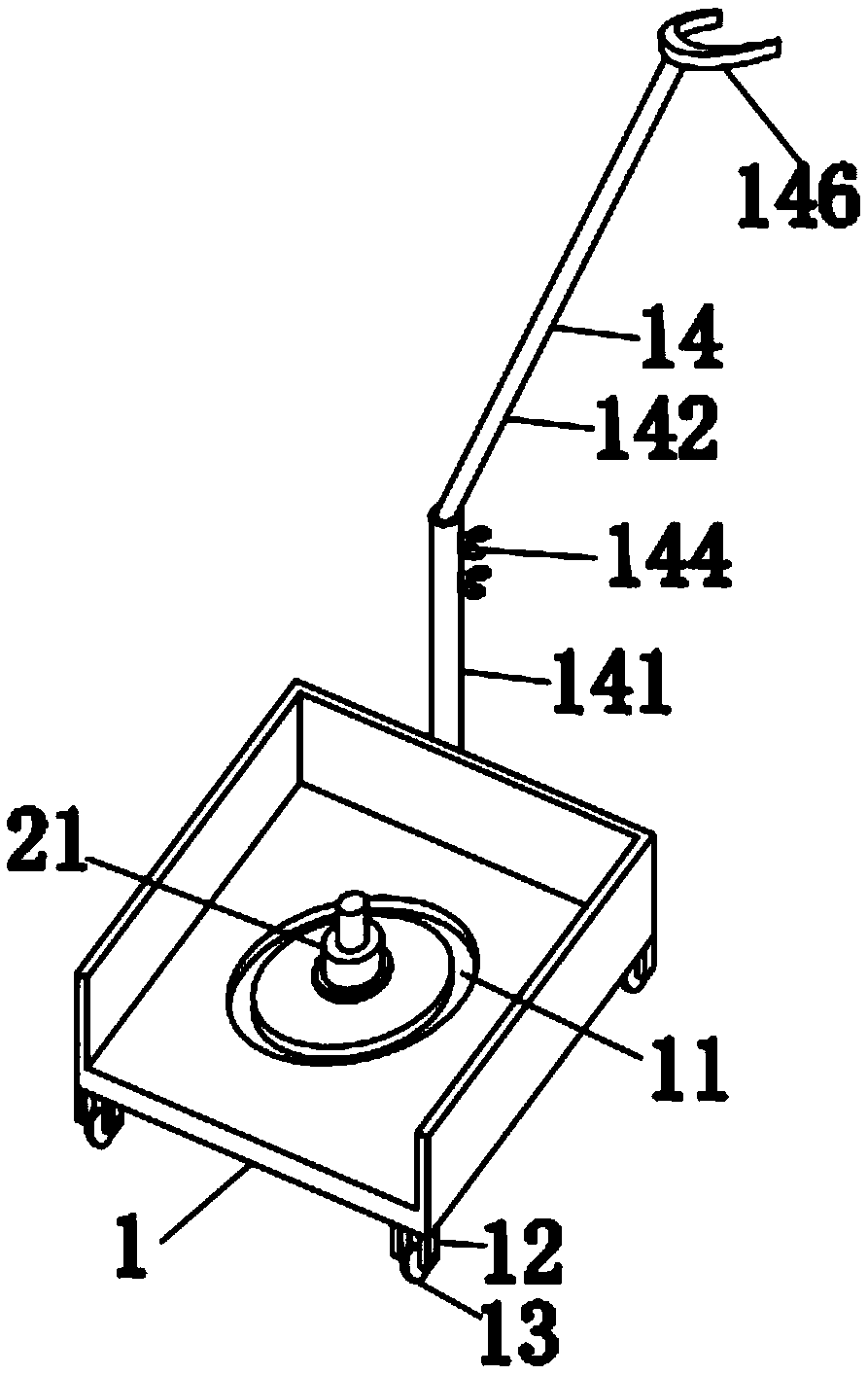

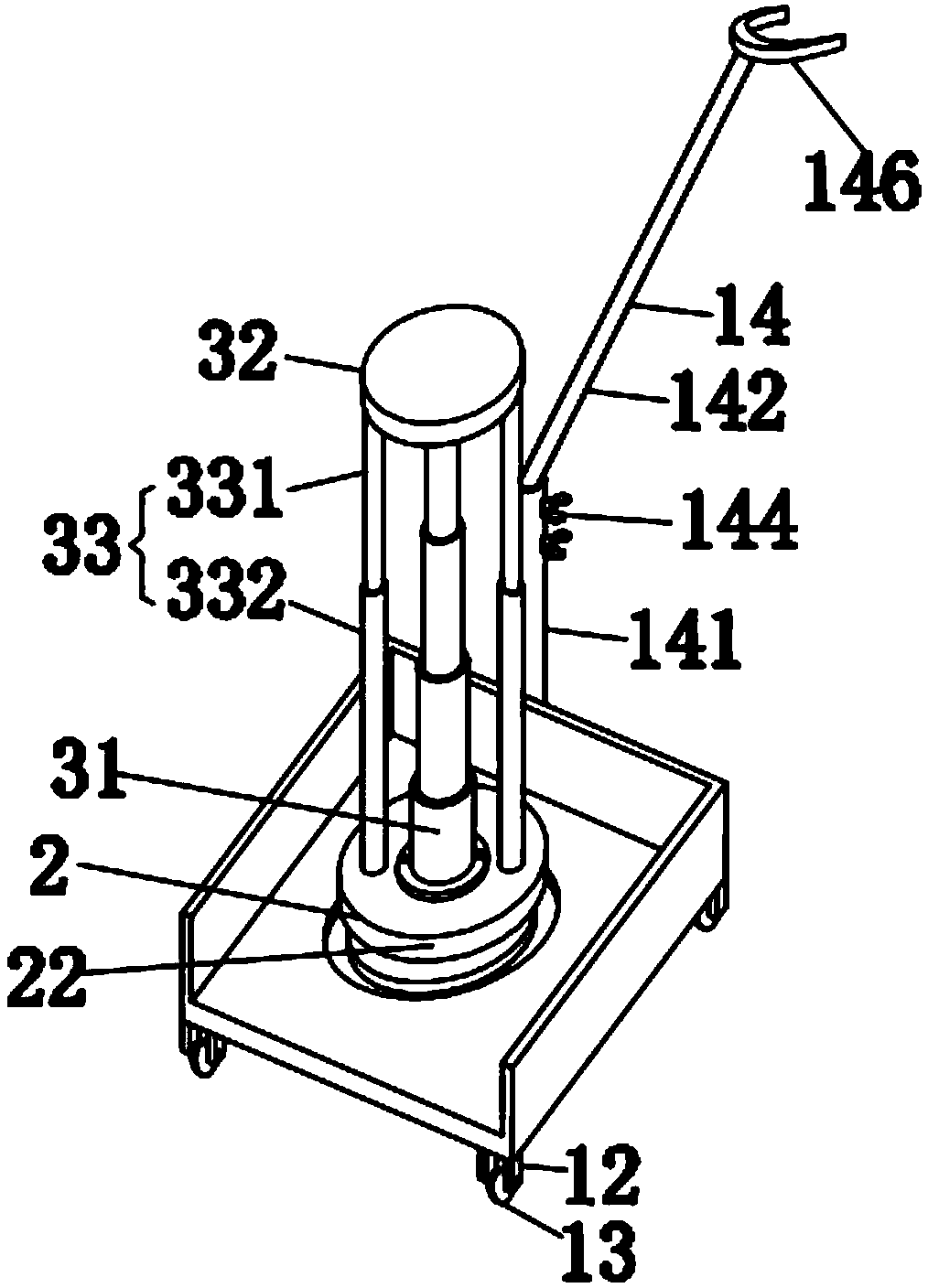

[0049] Such as figure 1 As shown, a semi-enclosed space 3D printer includes a bottom plate 1 and a 3D printing mechanism 5, and the top of the bottom plate 1 includes a horizontal telescopic mechanism 4, a vertical telescopic mechanism 3 and a rotation mechanism 2 in sequence from top to bottom;

[0050] Such as figure 1 and figure 2 As shown, the rotating mechanism 2 includes a first motor 21 and a first disk 22, the bottom of the first motor 21 is fixedly connected with the middle part of the upper end surface of the base plate 1 by bolts, and the middle part of the lower end surface of the first disk 22 is connected with the first The top welding of the output shaft of the motor 21;

[0051] Such as figure 1 and image 3 As shown, the longitudinal telescopic mechanism 3 includes a first cylinder 31 and a second disc 32, the bottom of the first cylinder 31 is fixedly connected with the middle part of the upper end surface of the first disc 22 by bolts, and the bottom of...

Embodiment 2

[0074] The difference from Example 1 is that the outer walls of the first inner rod 331 and the second inner rod 431 are sprayed with lubricating liquid, and the lubricating liquid is prepared by the following method:

[0075] Take the following raw materials and weigh them by weight: 10 parts of white oil, 4 parts of glycerin, 8 parts of turpentine, 7 parts of sorbitol, 4 parts of boric acid, 7 parts of glyceryl oleate, 3 parts of palmitoleic acid, 6 parts of antioxidant, 5 parts of antirust agent, 4 parts of defoamer;

[0076] A: Material preparation: first weigh the above raw materials;

[0077] B: Oleyl alcohol mixing: first pour white oil, glycerin, turpentine, and sorbitol into a constant temperature magnetic stirrer, turn on the constant temperature magnetic stirrer to stir and heat, the speed is 50r / min, and the temperature is controlled between 85 degrees Celsius;

[0078] C: Ester fusion: pour boric acid, glyceryl oleate and palmitoleic acid into a constant temperat...

Embodiment 3

[0083] The difference with embodiment 2 is the preparation of lubricating liquid, and its specific preparation method is as follows:

[0084] Take the following raw materials and weigh them by weight: 14 parts of white oil, 8 parts of glycerin, 10 parts of turpentine, 9 parts of sorbitol, 8 parts of boric acid, 11 parts of glyceryl oleate, 7 parts of palmitoleic acid, 10 parts of antioxidant, 7 parts of antirust agent, 8 parts of defoamer;

[0085] A: Material preparation: first weigh the above raw materials;

[0086] B: Oleyl alcohol mixing: first pour white oil, glycerin, turpentine, and sorbitol into a constant temperature magnetic stirrer, turn on the constant temperature magnetic stirrer to stir and heat, the speed is 70r / min, and the temperature is controlled between 95 degrees Celsius;

[0087] C: Ester fusion: pour boric acid, glyceryl oleate and palmitoleic acid into a constant temperature magnetic stirrer and stir for 30 minutes;

[0088] D: Additives: Pour the ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com