Wafer holding device in vacuum prewet cavity

A technology for pre-wetting chambers and wafers, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., and can solve problems such as wafer removal troubles, wafer slipping, voids, etc., and achieves easy insertion and removal, and design structure Reasonable, good effect of exclusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific drawings and embodiments.

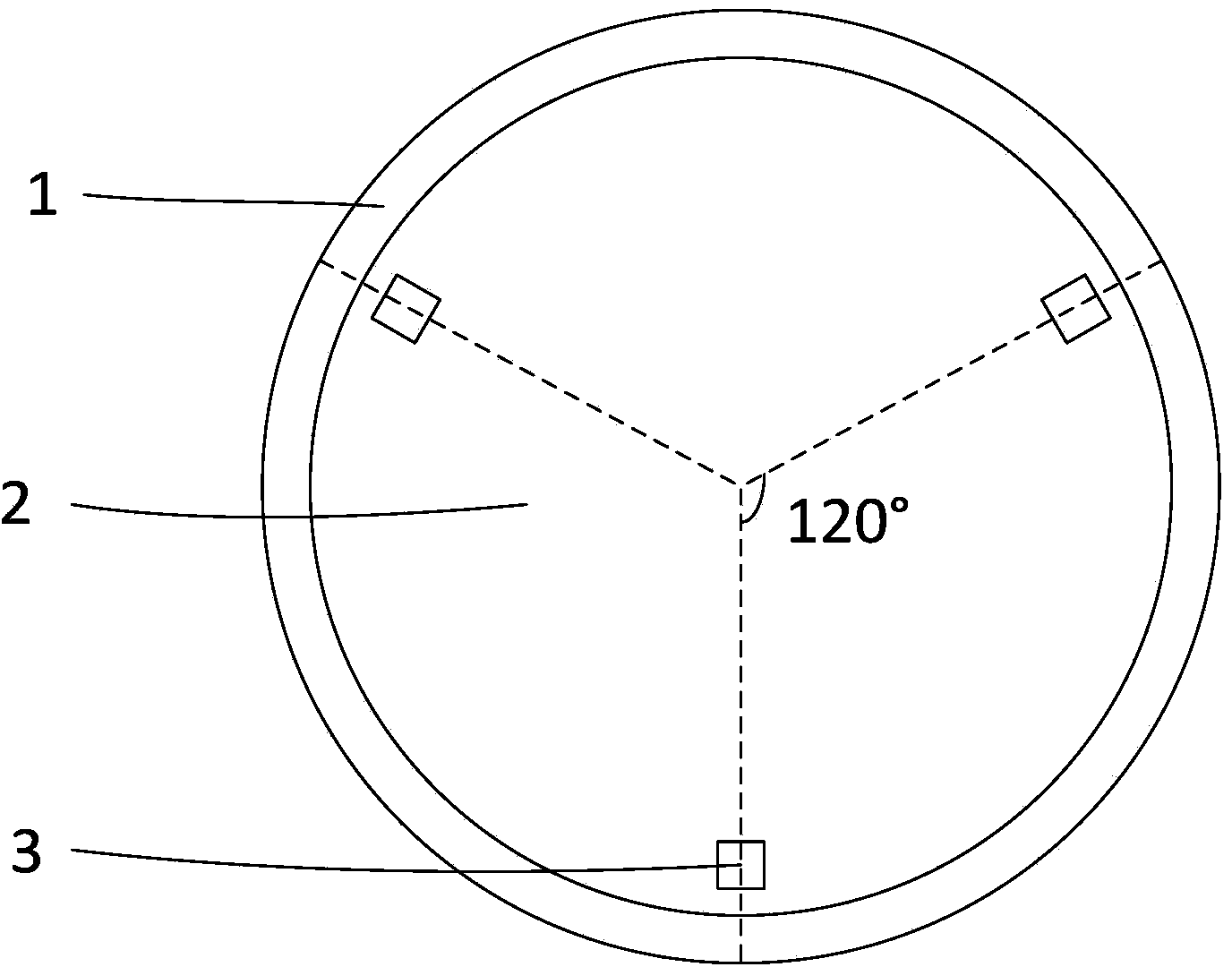

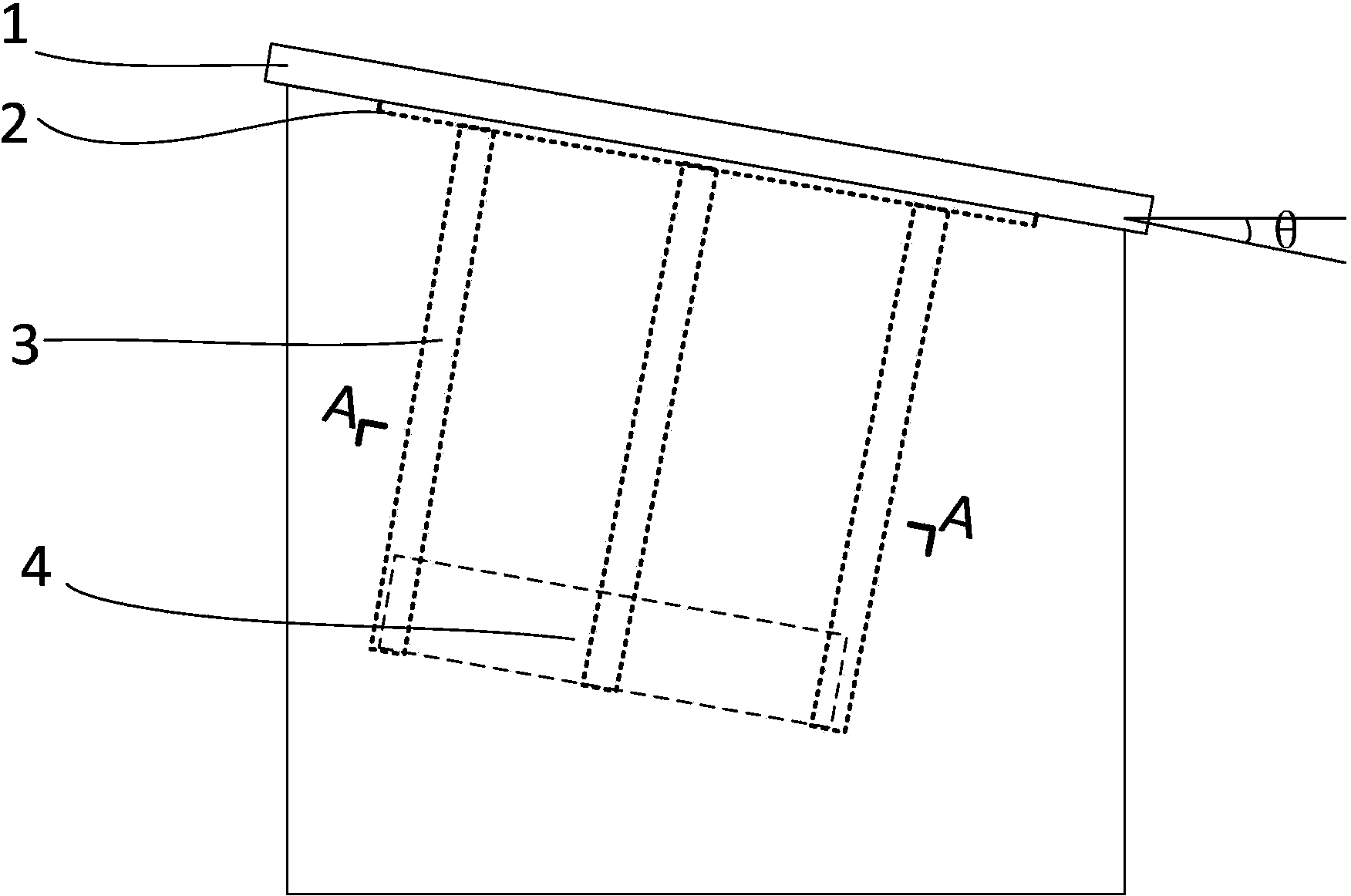

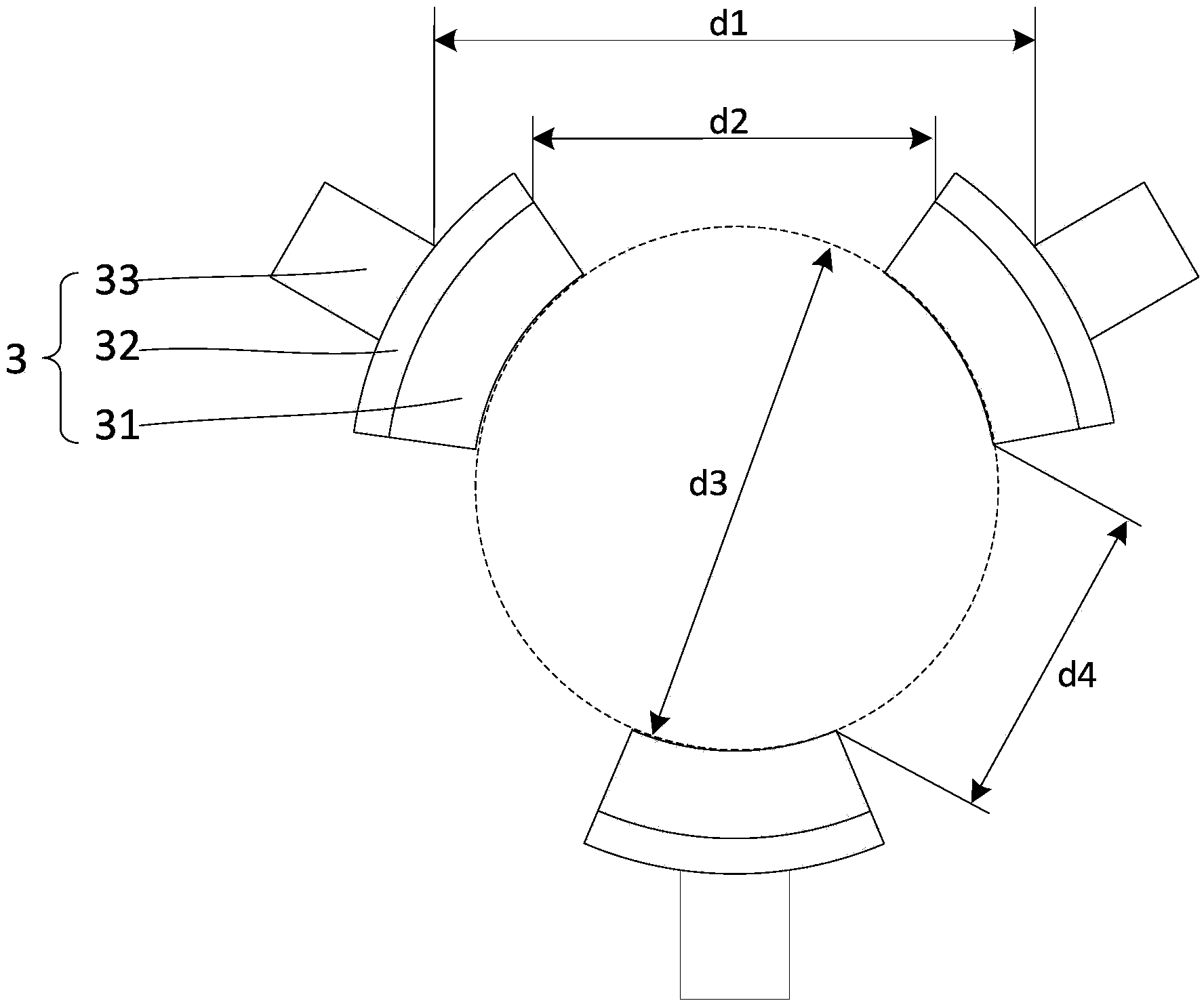

[0021] like figure 1 , as shown in Figure 2: a wafer holding device in a vacuum pre-wet chamber, including a chamber cover 1 arranged on the top of the pre-wet chamber, a gasket 2 is connected under the chamber cover 1, and the gasket 2 is preferably a circular pad The cavity cover 1 is arranged obliquely, and has an included angle with respect to the horizontal plane; several suspenders 3 are connected under the spacer 2, and the bottoms of each suspender 3 are bent inward to form a wafer placement platform for carrying wafers together. part 4. Each suspender 3 is approximately perpendicular to the cavity cover 1 .

[0022] figure 2 middle θ is the angle between the chamber cover 1 placed on the vacuum pre-humidification chamber and the horizontal plane, and the variation range of this angle is ±15°, and is not equal to 0°.

[0023] Wafer Placement Depa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com