Apparatus for peeling insulating layer of lead

A wire insulation and guide wheel technology is applied in the field of auxiliary tooling for power production, which can solve the problems of insecurity, high price, damage to the environment, etc., and achieve the effects of being convenient for carrying out operations, high stripping efficiency, and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with drawings and embodiments.

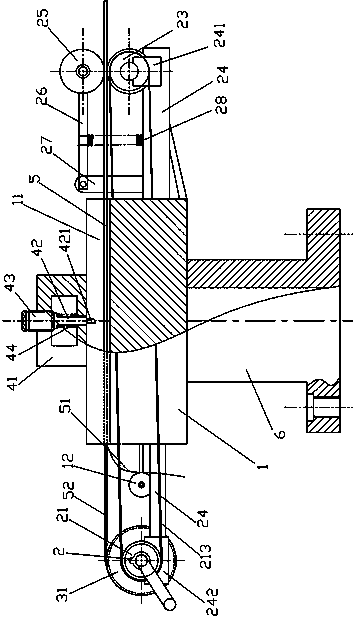

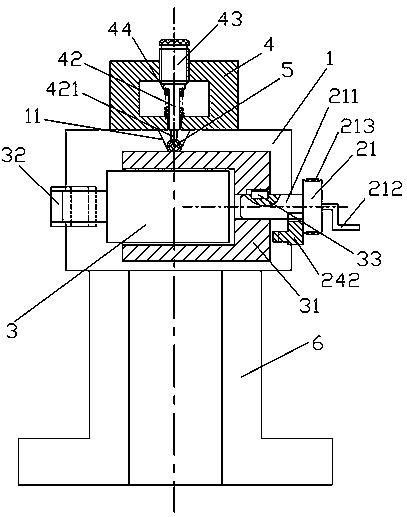

[0022] Such as figure 1 As shown, the present invention includes a base 6, a workbench 1 arranged on the upper surface of the base 6, a transmission mechanism 2 arranged on both sides of the workbench 1, a winding mechanism 3 connected to the transmission mechanism 2, and a wire winding mechanism 3 arranged on the upper surface of the workbench 1. The cutting mechanism 4;

[0023] Such as figure 2 As shown, a V-shaped groove 11 is provided along the top horizontal direction of the workbench 1 .

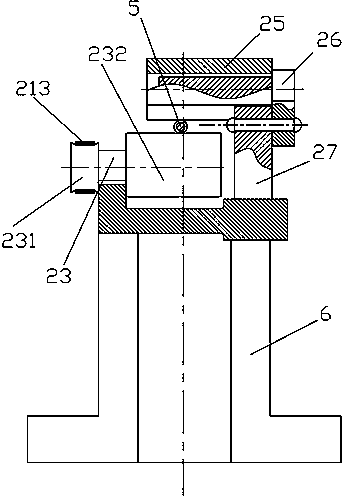

[0024] Transmission mechanism 2 comprises belt pulley 21, fixed guide wheel 23, two outer convex plates 24, movable guide wheel 25, movable guide wheel support 26, vertical plate 27, adjustment spring 28; figure 1 As shown, an outer convex plate 24 is respectively provided on both sides of the workbench 1, and one end of the outer convex plate 24 on the right is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com