Beverage dispenser with improved nozzle assembly

A technology of beverage and nozzle, applied in the field of beverage dispensing machine with improved nozzle assembly, which can solve the problems of difficult, limited and difficult cleaning of changing and improving equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

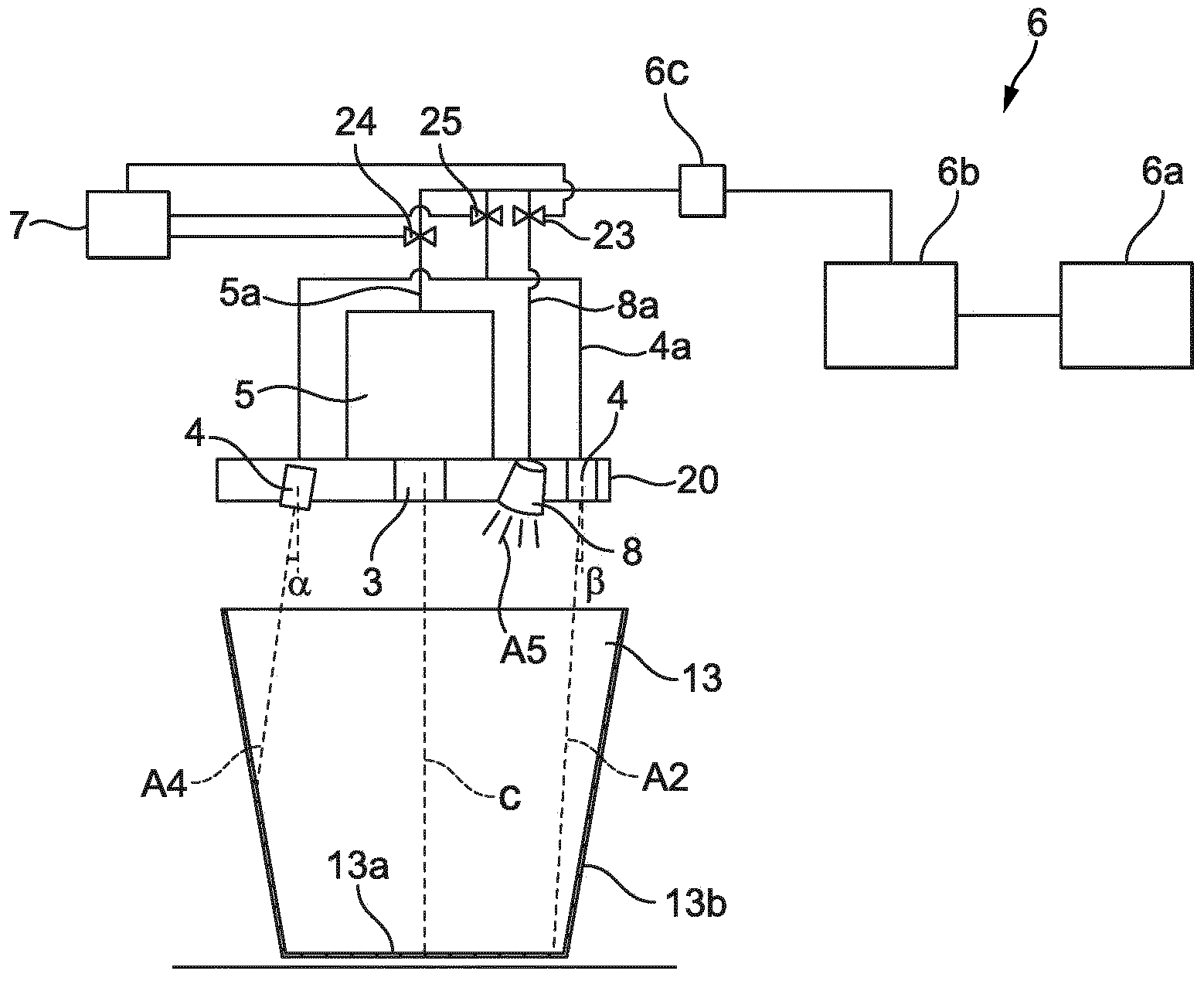

[0042] figure 1 is a schematic diagram of a dissolving device of a dispensing machine according to the prior art. Depend on figure 1 It can be seen that the plate member 2 comprises four nozzles 4 (only two shown). Furthermore, the plate member comprises an outlet 3 which is in fluid connection with a coffee mixing chamber 5 mounted on the plate member. The plate member 2 preferably comprises a spray nozzle 8 designed to inject a spray A5 into a container placed below the plate member 2 . The nozzle 4, the spray nozzle 8 and the mixing chamber 5 are in fluid connection with the diluent supply 6 of the apparatus. The diluent supply means preferably comprises a water tank 6a or reservoir adapted to supply diluent to the device. It should be noted that instead of a reservoir, the device could be connected to a water tap for a permanent supply of diluent. The diluent supply means includes a pump 6 b which is connected to the reservoir and supplies diluent to the boiler 6 c of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com