A staggered vibrating subsoiling and fertilizing machine

A staggered, all-in-one machine technology, used in planter parts, agricultural machinery and implements, shovels, etc., can solve the problems of unreasonable structure, poor environmental protection effect, complex mechanical structure, etc., achieve reasonable structure design, improve deep loosening Effect, solve the effect of single performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

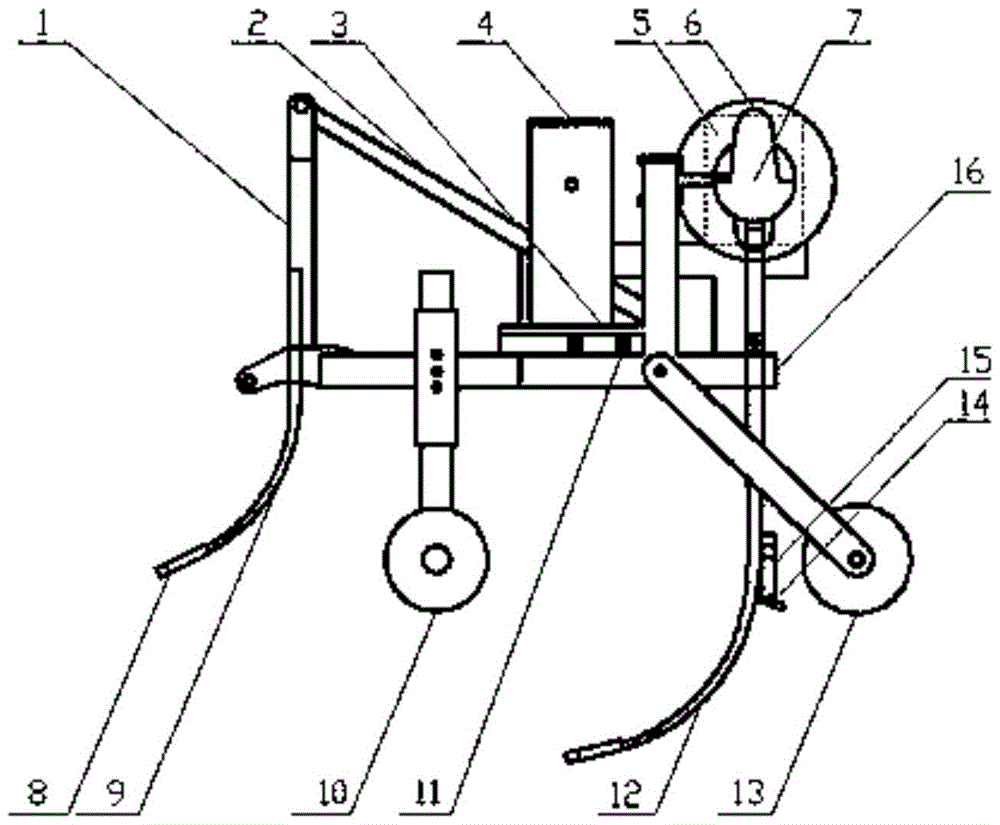

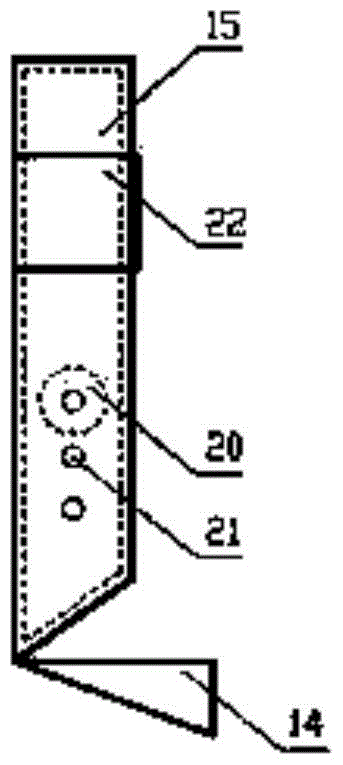

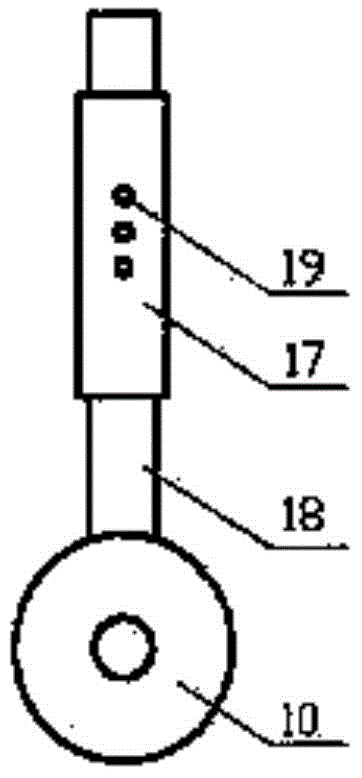

[0019] Referring to the accompanying drawings, the vibration subsoiling device, depth control device, fertilization device and traction device of the staggered vibratory subsoiling fertilizer applicator are all installed in the figure 1 on the rack shown. The subsoiling device is respectively placed in the front and the middle of the frame 16, the staggered subsoiling vibration device is connected with the output shaft of the motor 5, the depth control device is placed on both sides of the frame 16, and the fertilization device is placed at the rear of the frame. The traction device is placed in the front portion of the frame 16 to be connected with the tractor's traction device.

[0020] See attached figure 1 , a specific example of the present invention comprises frame 16, is arranged on frame 16 and is used for the suspension bracket 1 that is articulated with agricultural locomotive and is fixed on frame 16 and is used for being connected with rotating shaft 23 motor 5. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com