On-line waistline cutting and rotating pitch-variable assembly for disposable sanitary product

A sanitary product, disposable technology, applied in application, medical science, clothing, etc., can solve the problems of poor speed and inability to directly compound, and achieve the effect of precise phase control, compact structure, and small host space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

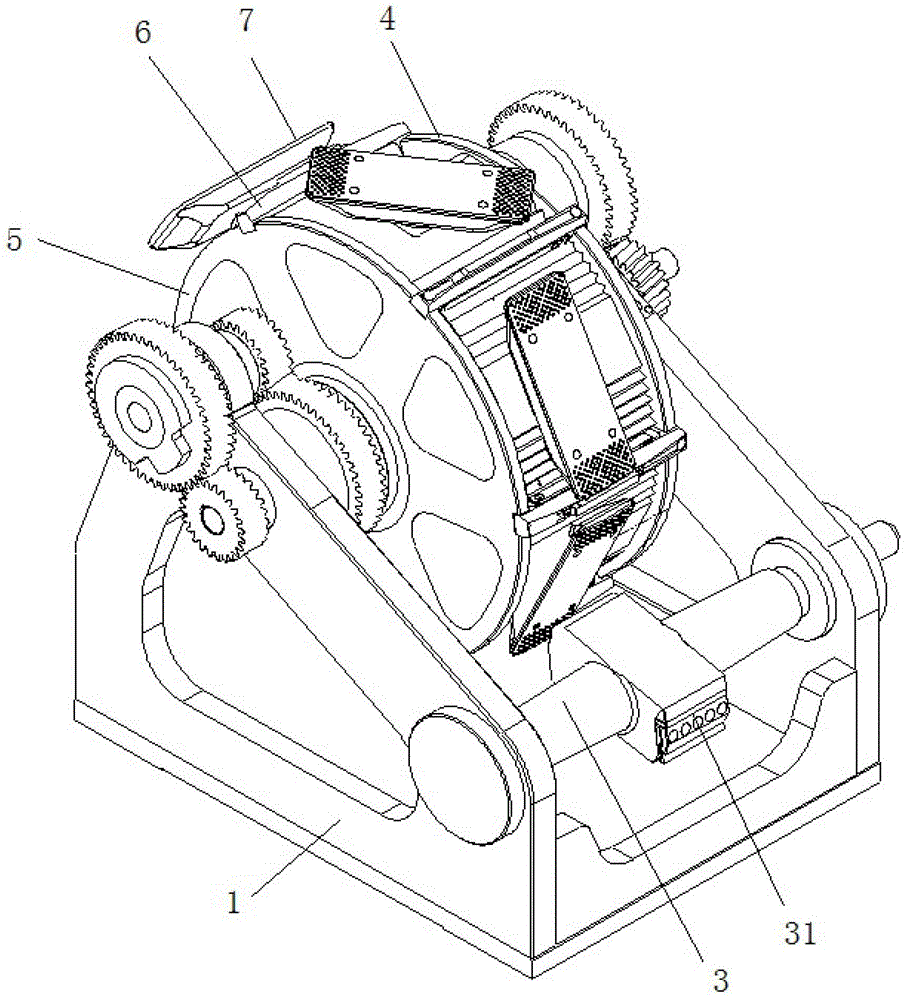

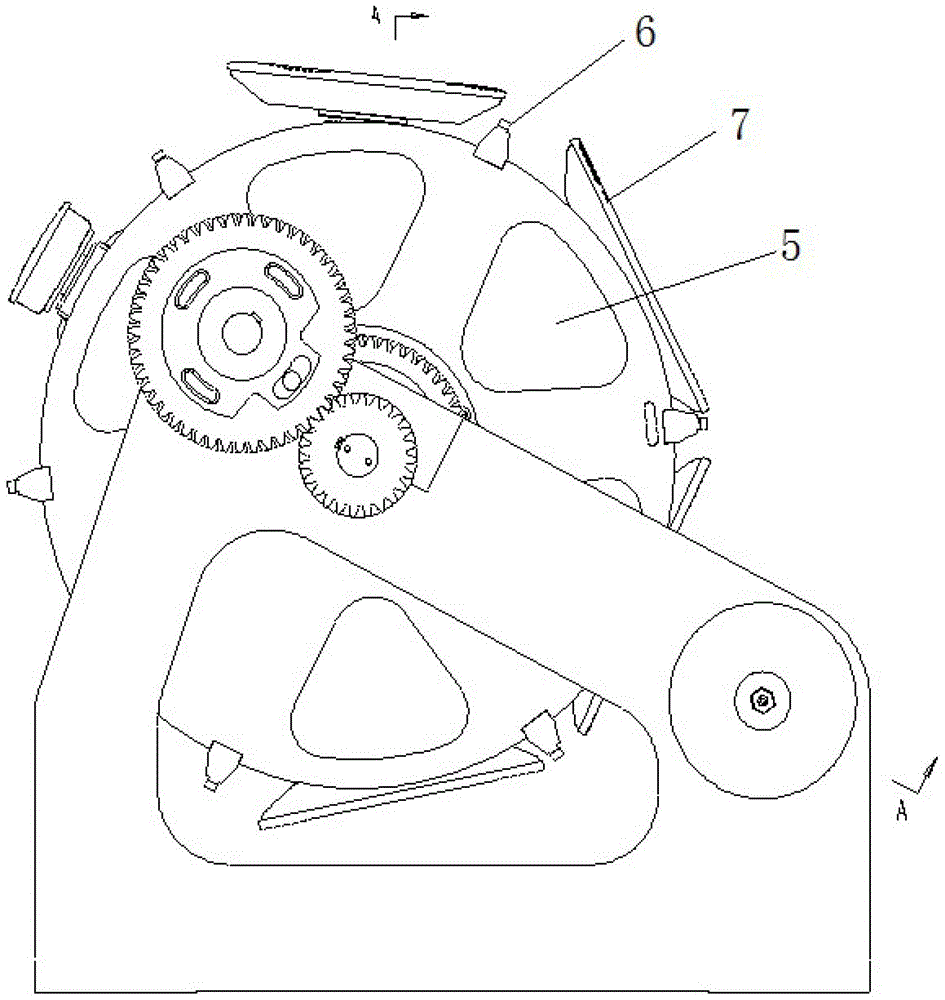

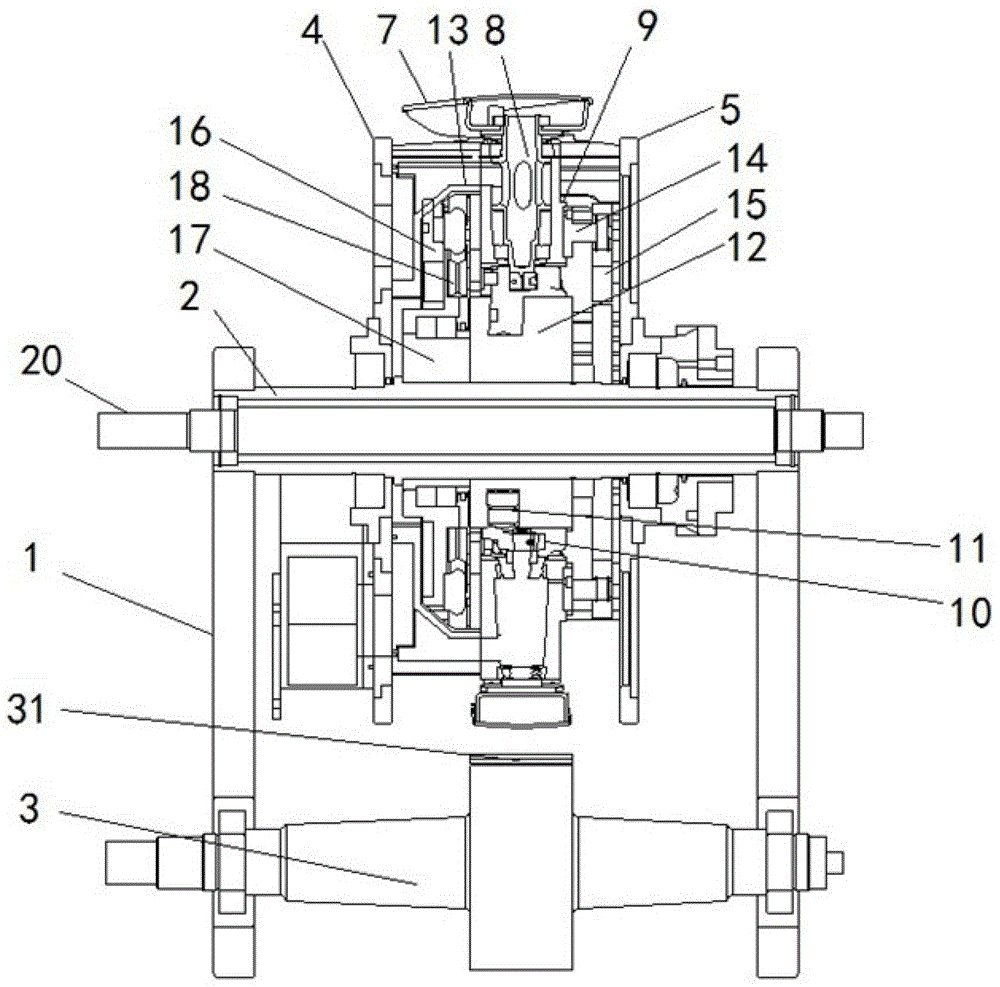

[0025] See Figure 1 to Figure 4 As shown, an on-line waistline cutting and rotating pitch-changing assembly of a disposable sanitary product is composed of a cutting mechanism, a reversing mechanism and a speed change mechanism. The three mechanisms are respectively fixed on the assembly frame 1, and the cutting mechanism It includes a bearing seat 2 fixed on the assembly frame 1, a drive shaft 20 and a cutter roller 3, the two ends of the bearing seat 2 are respectively equipped with a cutter head 4 and a rotating disc 5 through bearings, and the drive shaft passes through the bearing sleeve In the bearing housing 2, two-stage reduction transmission gears are respectively installed at both ends of the drive shaft to drive the cutterhead and the rotating disk respectively. The cutting knives 31 are engaged, and there are suction cups 7 distributed between two adjacent anvils 6; the anvils 6 and the suction cups 7 both have six.

[0026] See figure 1 and image 3 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com