Patents

Literature

42results about How to "Precise phase control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

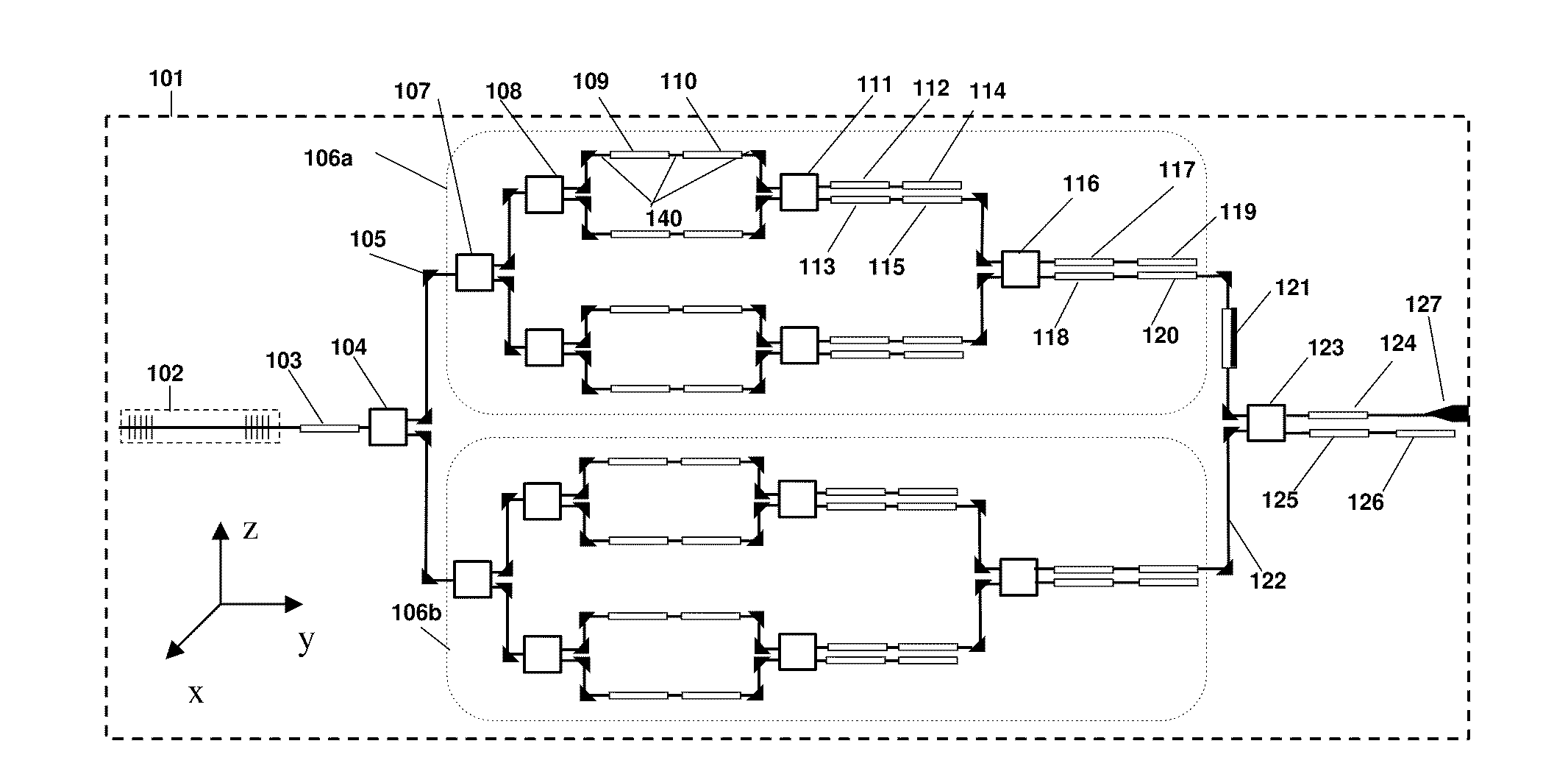

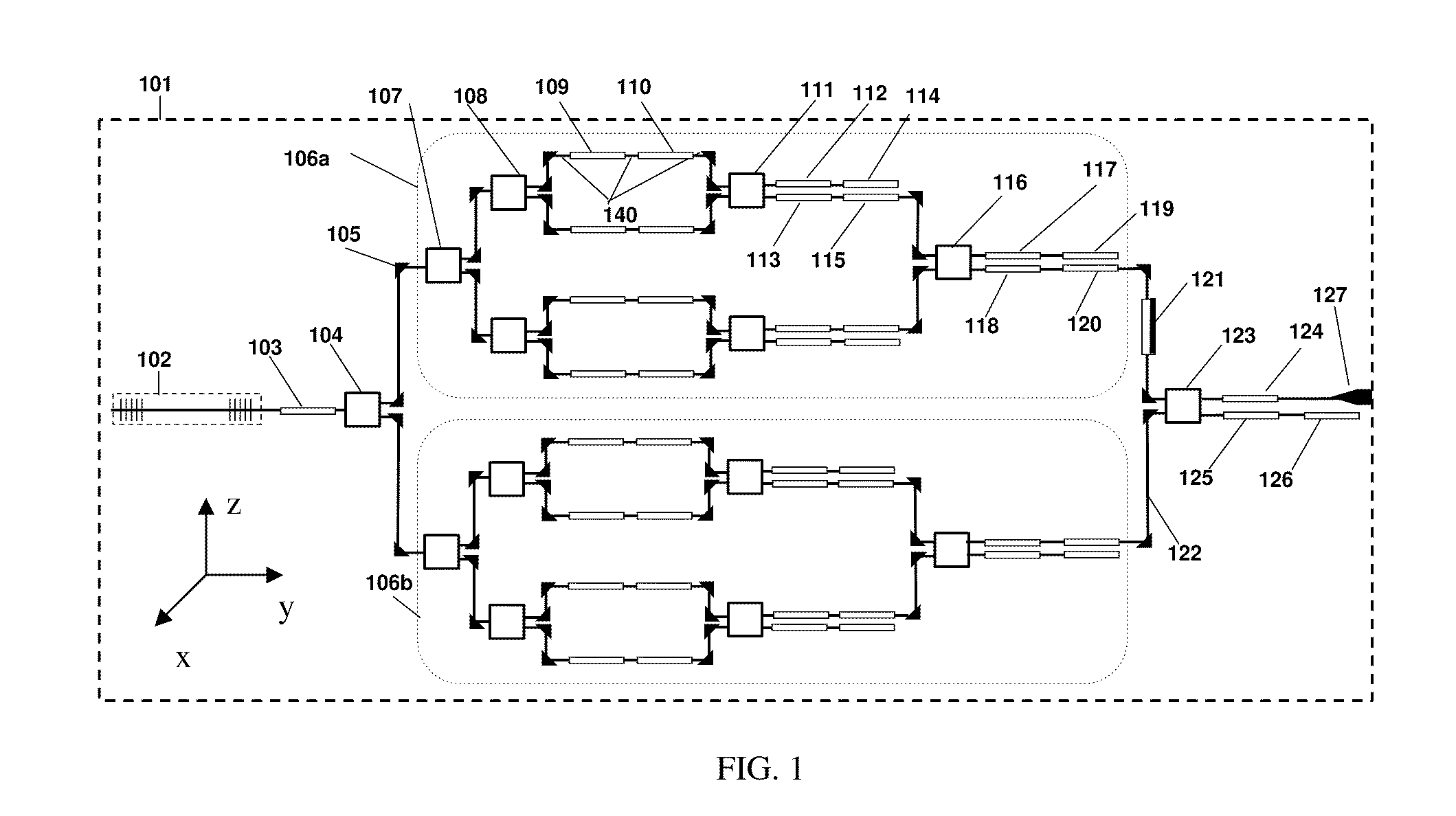

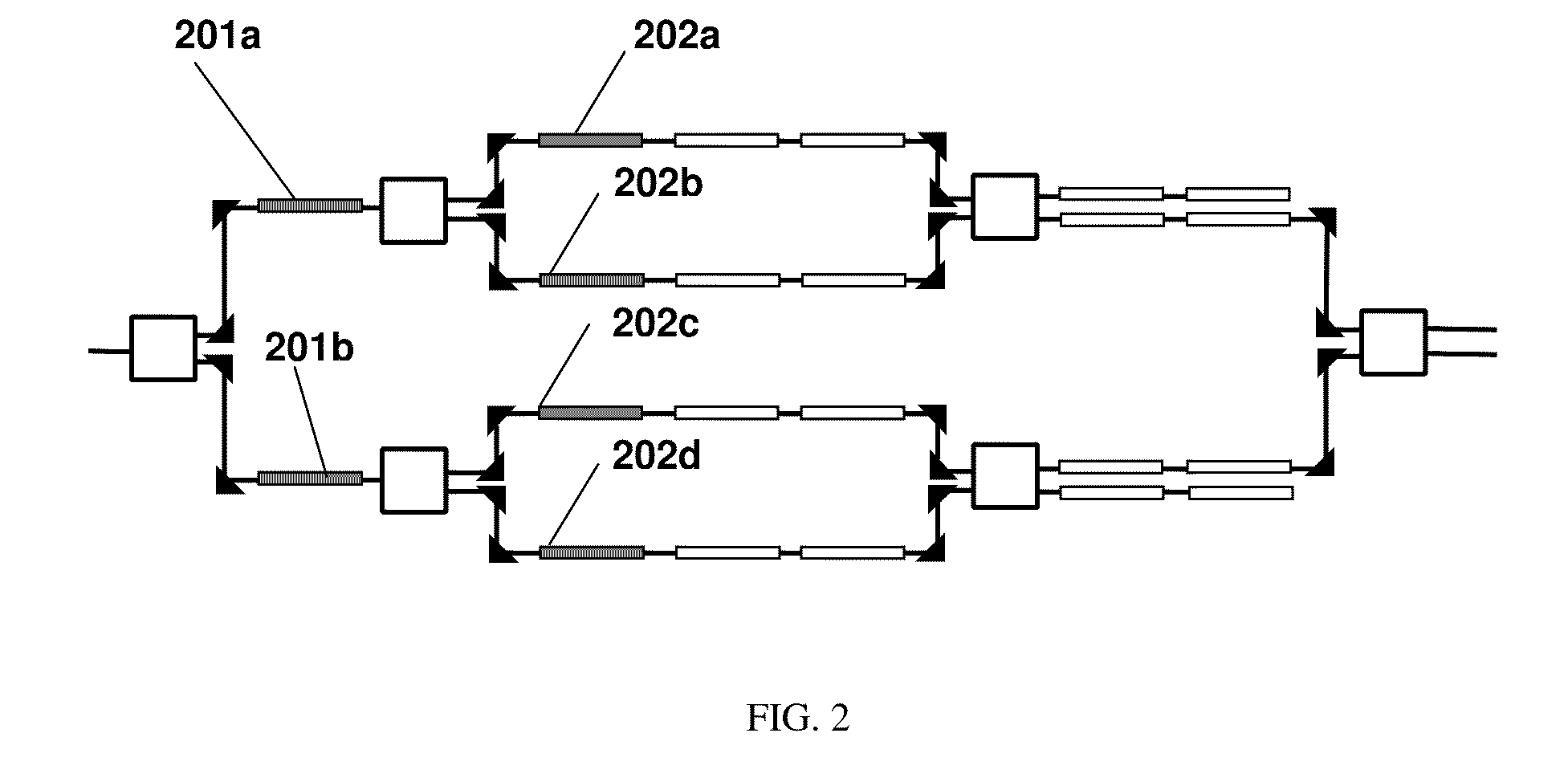

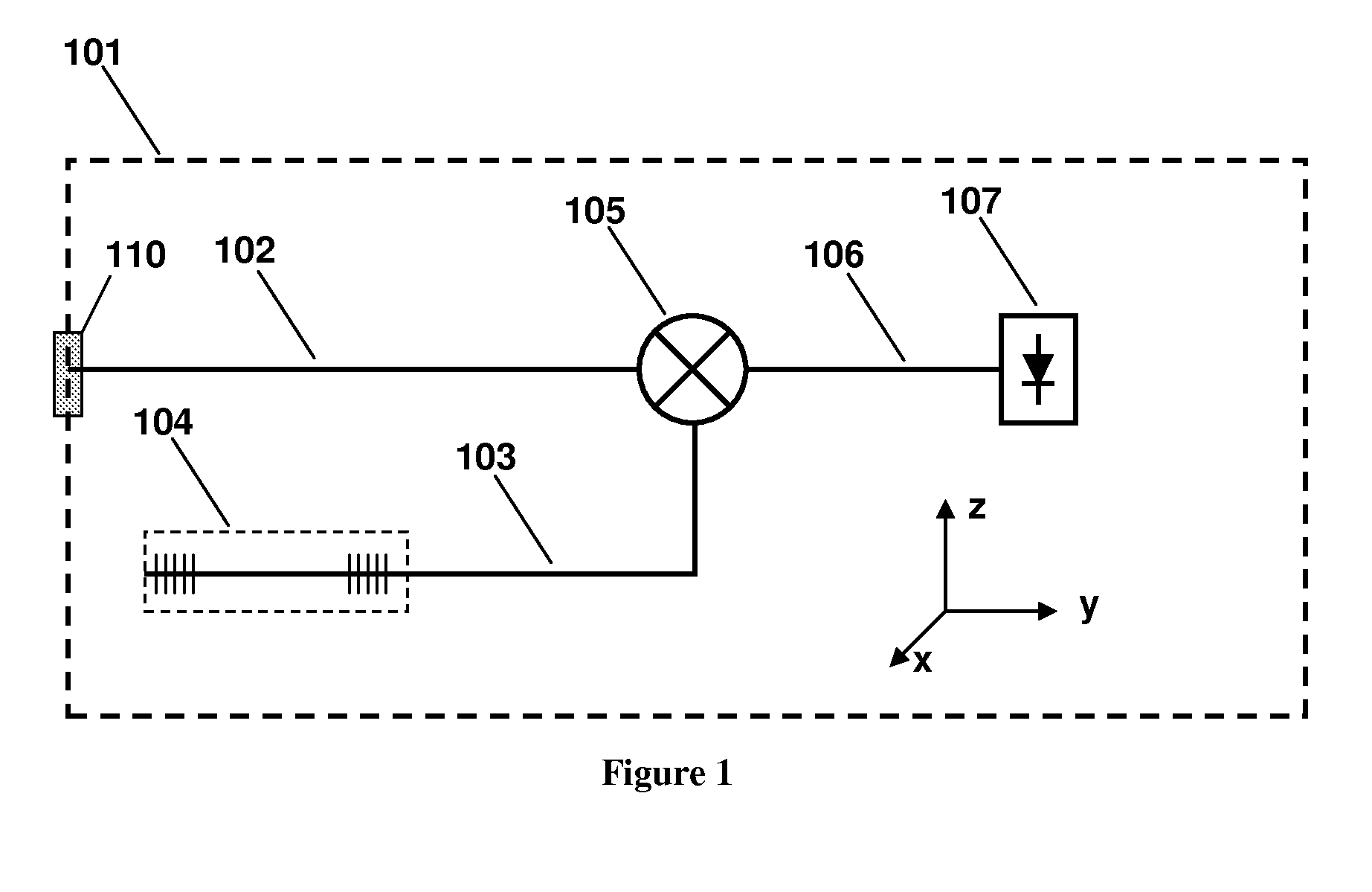

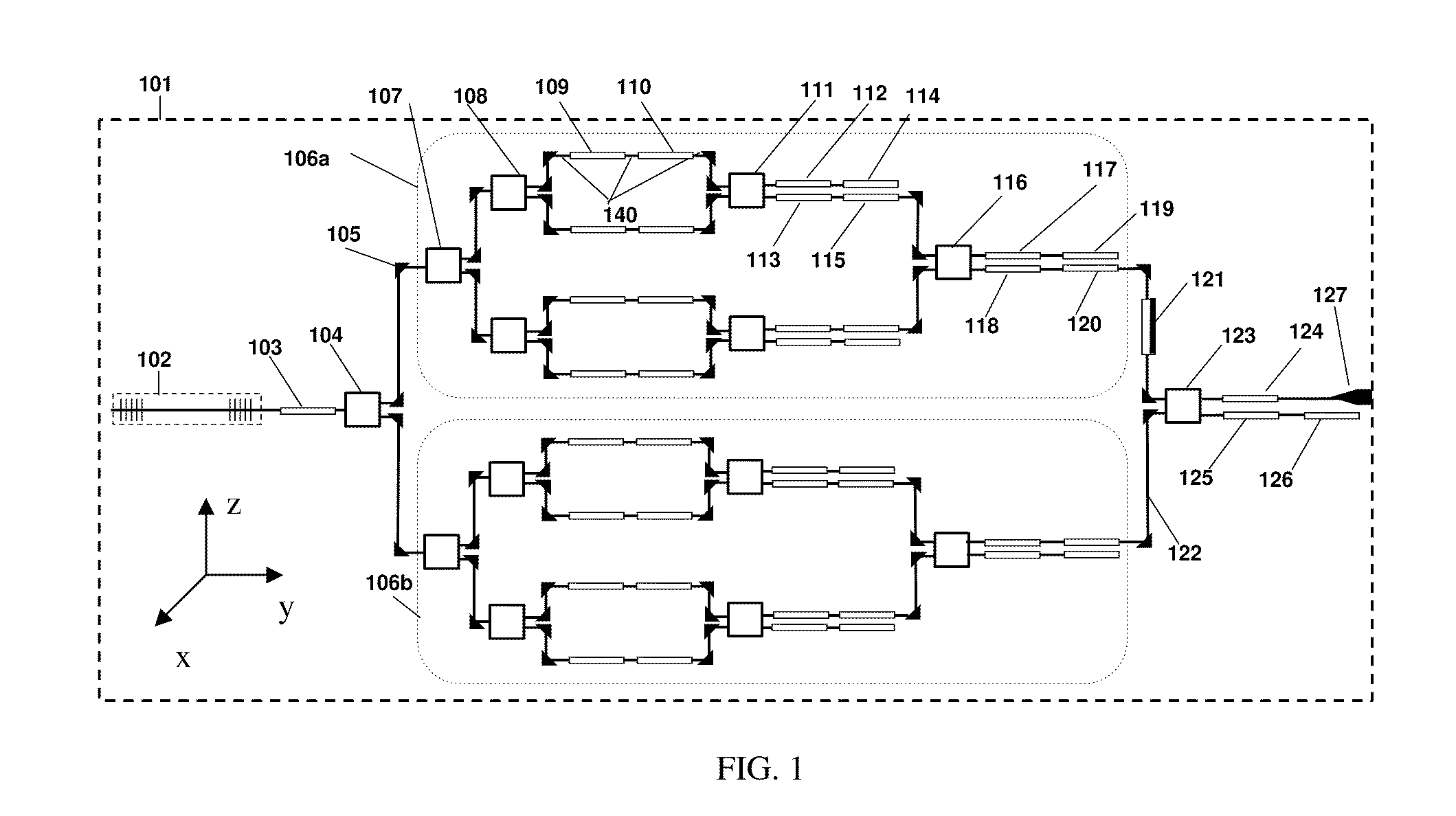

Chip-based advanced modulation format transmitter

ActiveUS20100303469A1Reduce mold sizeReduced footprintWavelength-division multiplex systemsElectromagnetic transmittersPhase modulationLaser source

In various embodiments, a monolithic integrated transmitter, comprising an on-chip laser source and a modulator structure capable of generating advanced modulation format signals based on amplitude and phase modulation are described.

Owner:FREEDOM PHOTONICS LLC

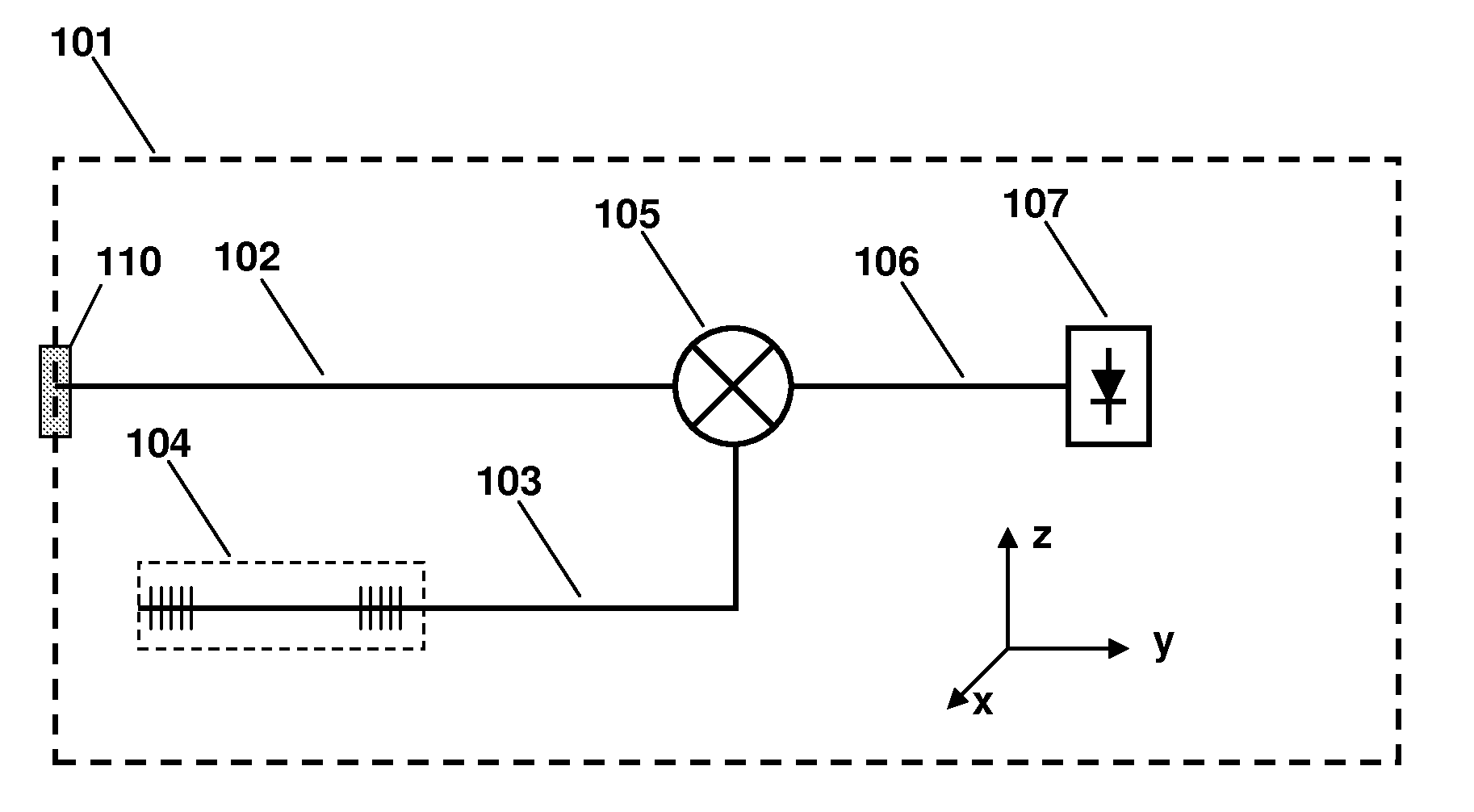

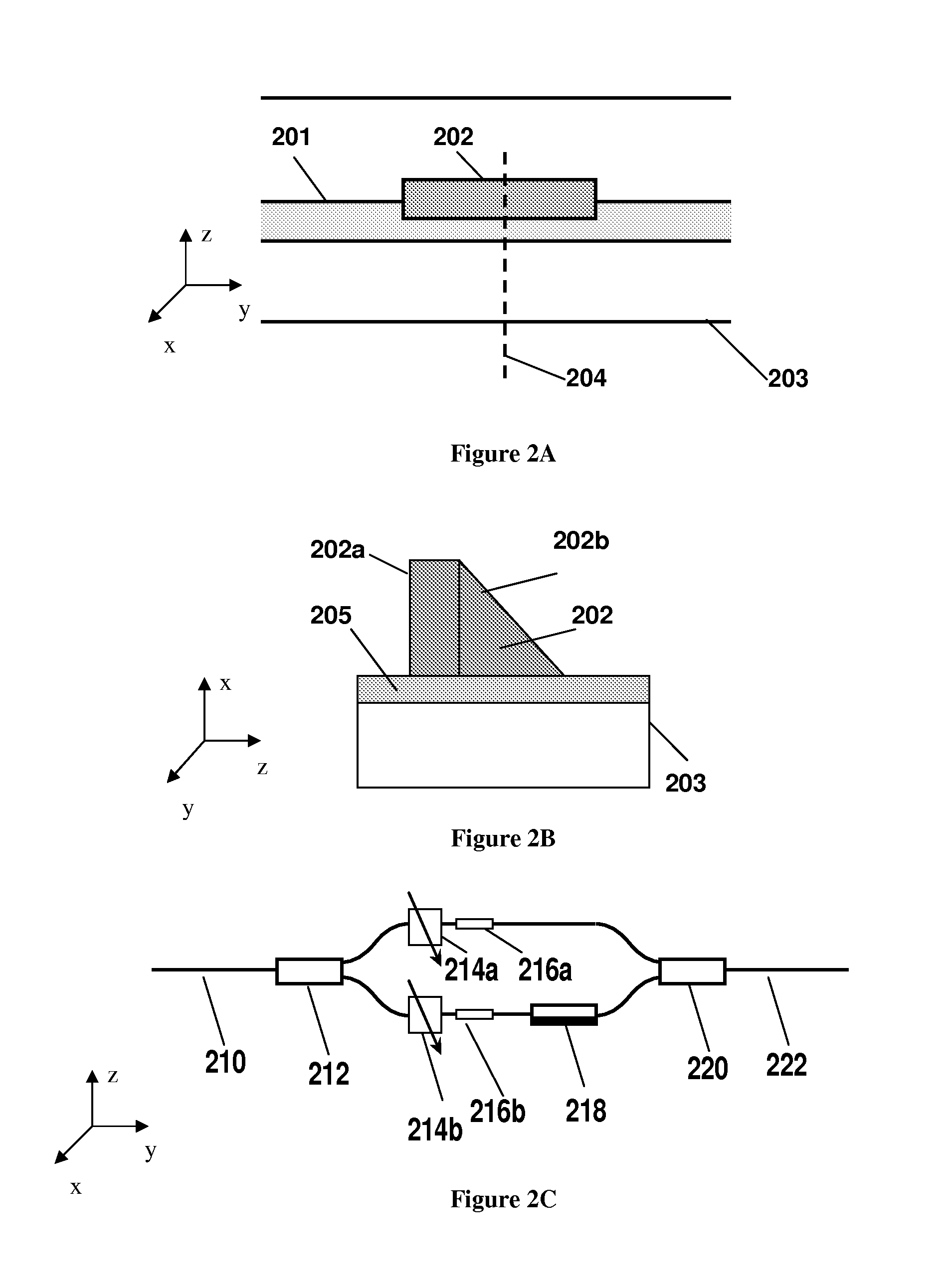

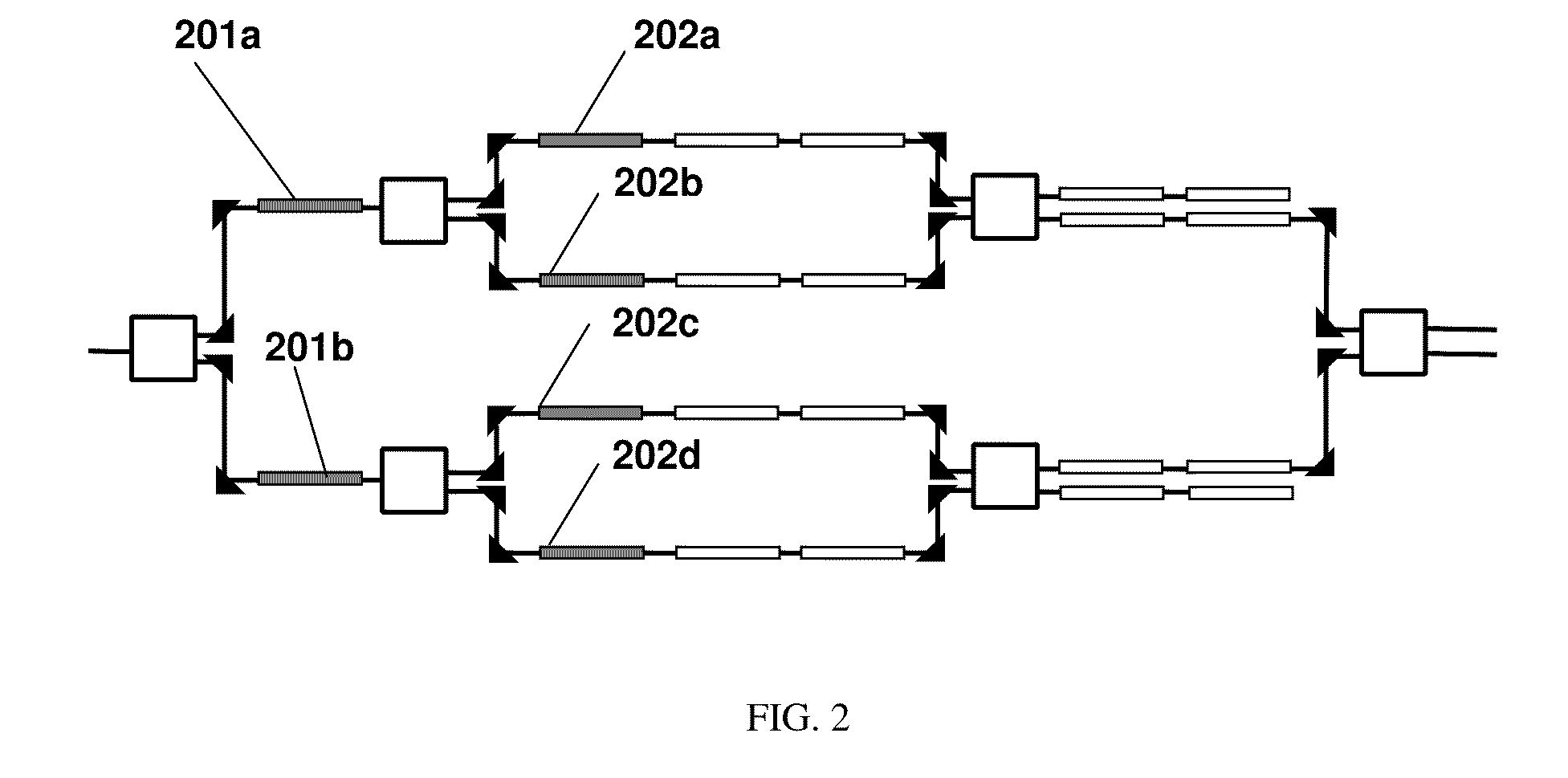

Monolithic widely-tunable coherent receiver

ActiveUS20100303476A1Reduce mold sizeIncrease productionWavelength-division multiplex systemsPolarising elementsLocal oscillatorLength wave

Various embodiments of a coherent receiver including a widely tunable local oscillator laser are described herein. In some embodiments, the coherent receiver can be integrated with waveguides, optical splitters and detectors to form a monolithic optical hetero / homodyne receiver. In some embodiments, the coherent receiver can demodulate the full phase information in two polarizations of a received optical signal over a range of optical wavelengths.

Owner:FREEDOM PHOTONICS LLC

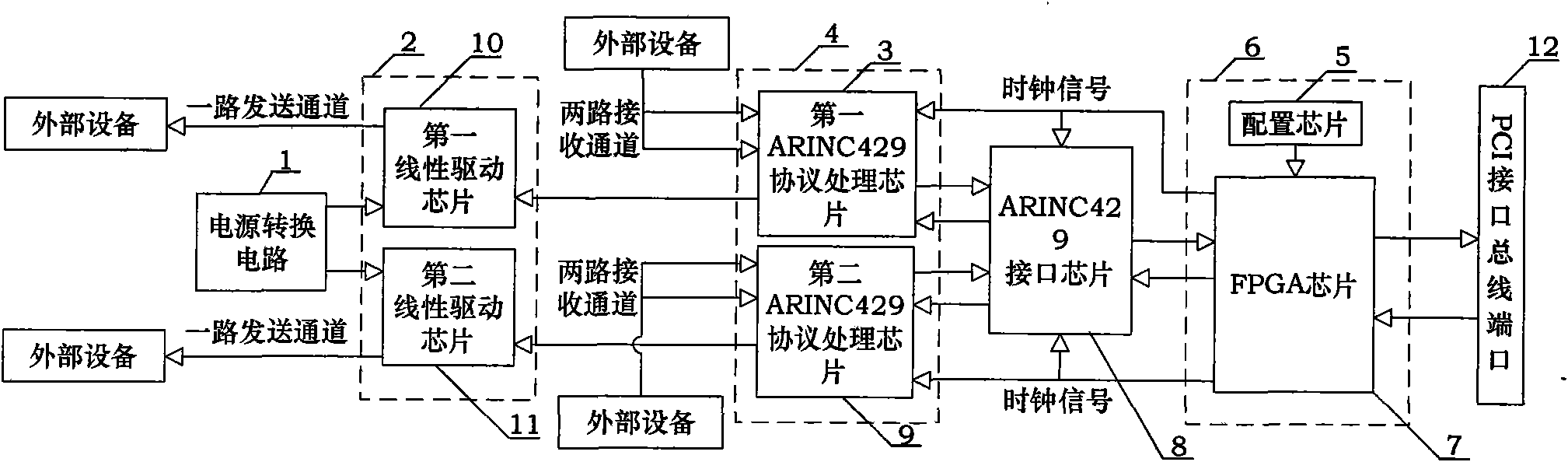

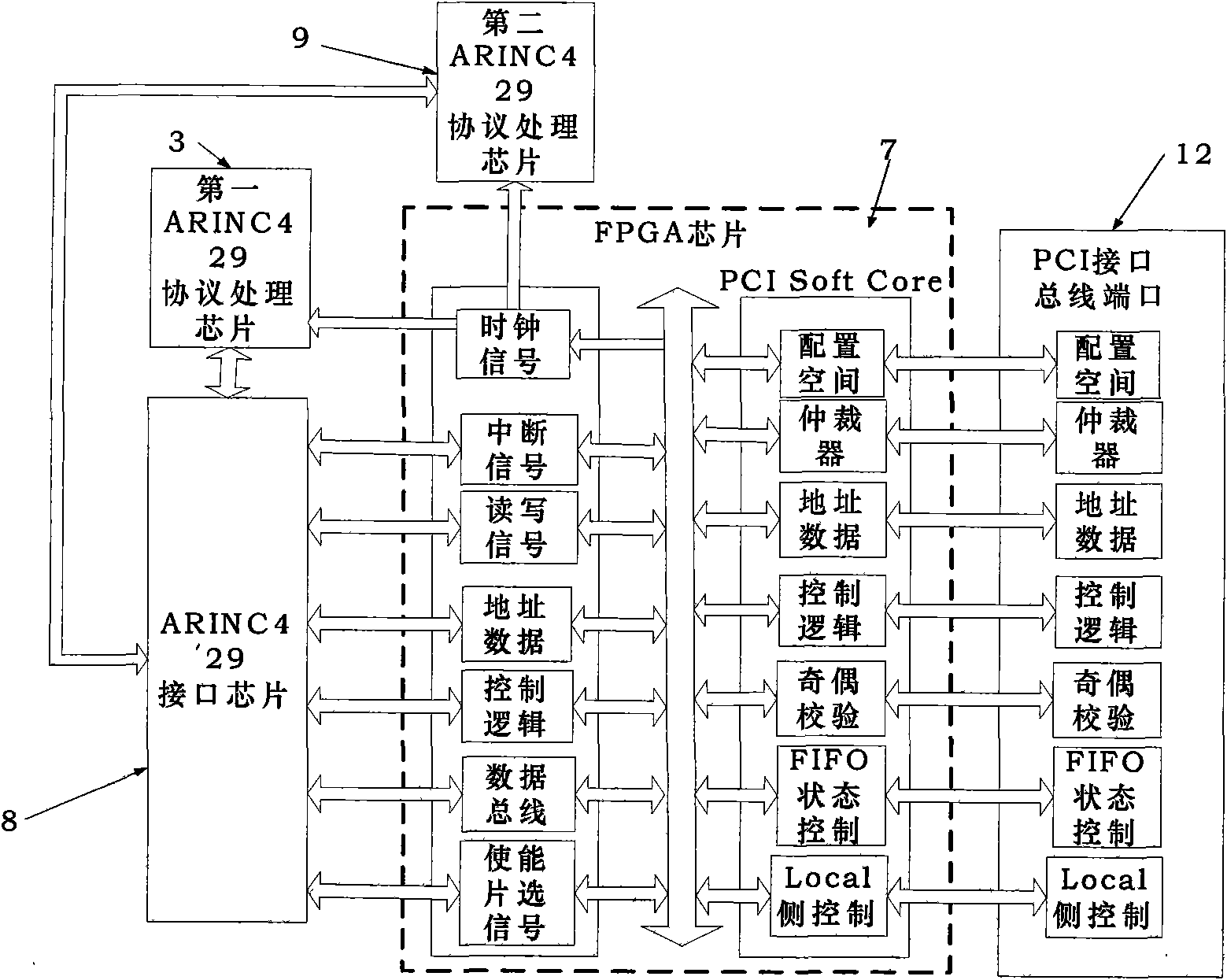

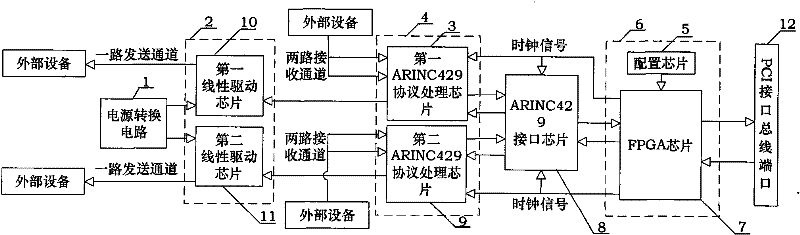

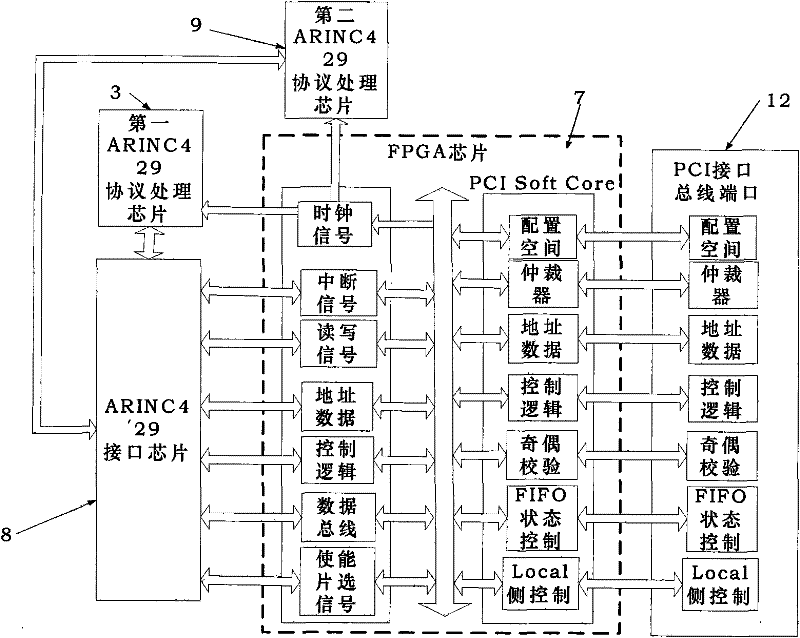

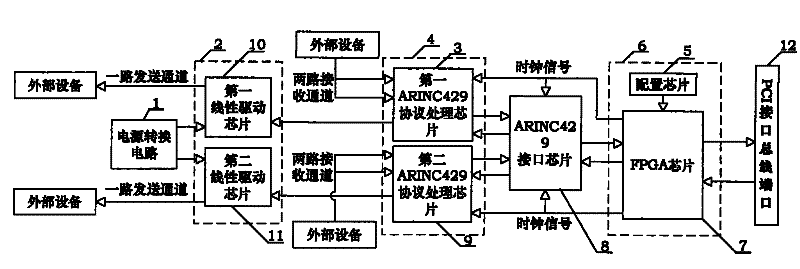

PCI integrated circuit board device used for ARINC429 communication

InactiveCN101571842ASimple structureIncrease flexibilityElectric digital data processingProtocol processingPci interface

The invention discloses a PCI integrated circuit board device used for ARINC429, mainly comprising an FPGA module, an ARINC429 interface chip, two ARINC429 protocol processing chips, two ARINC429 signal output linear drive chips and a power switching circuit. The FPGA chip is used for realizing PCI interface protocol and completing information interaction and control of a host computer and the board; the FPGA chip executes instruction of the host computer, initializes the ARINC429 interface chip and realizes control and caching of sending and receiving data to realize independent four receiving and two sending function and data sending rate adjustable function. The invention is flexible in configuration, the sending rate is adjustable and is wide in adjustable range, circuit construction is simple, processing cost of the circuit board is low, and different requirements of ARINC429 communication can be completed only by modifying FPGA software without changing hardware, thus the invention has strong commonality and flexibility.

Owner:BEIHANG UNIV

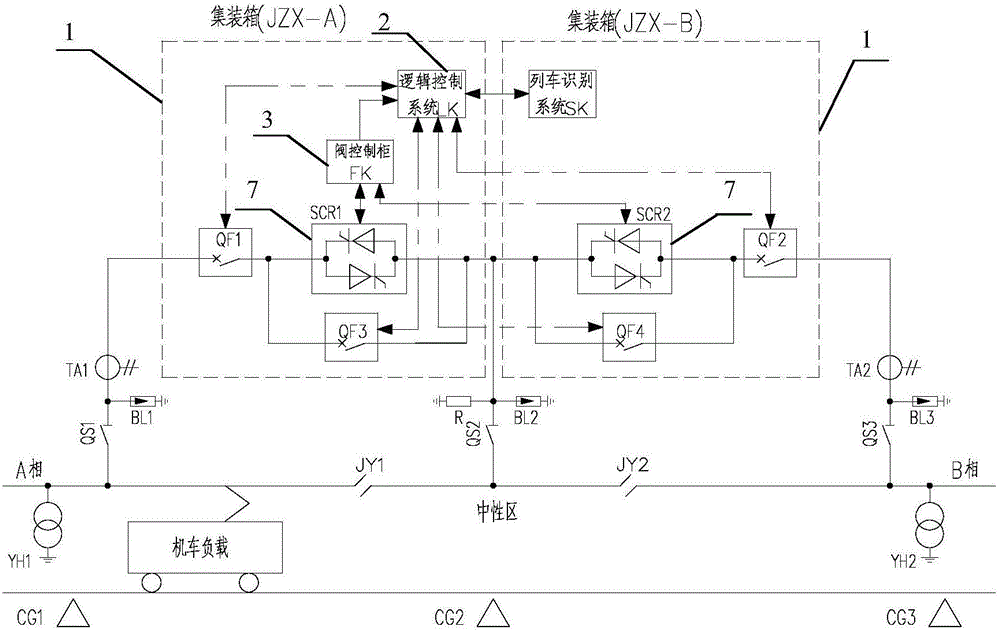

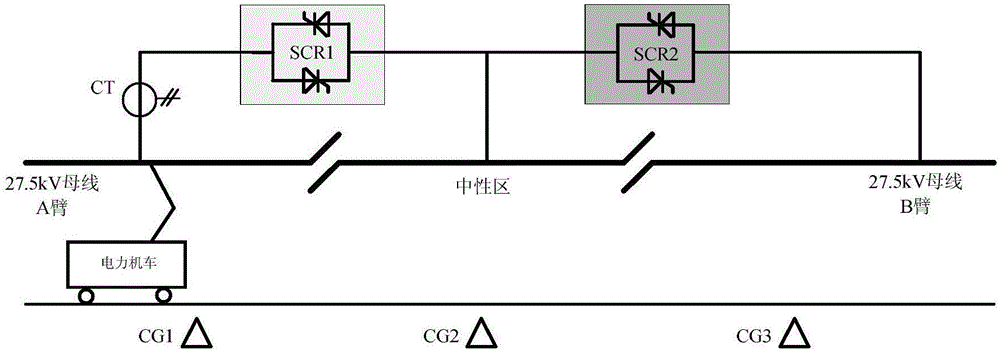

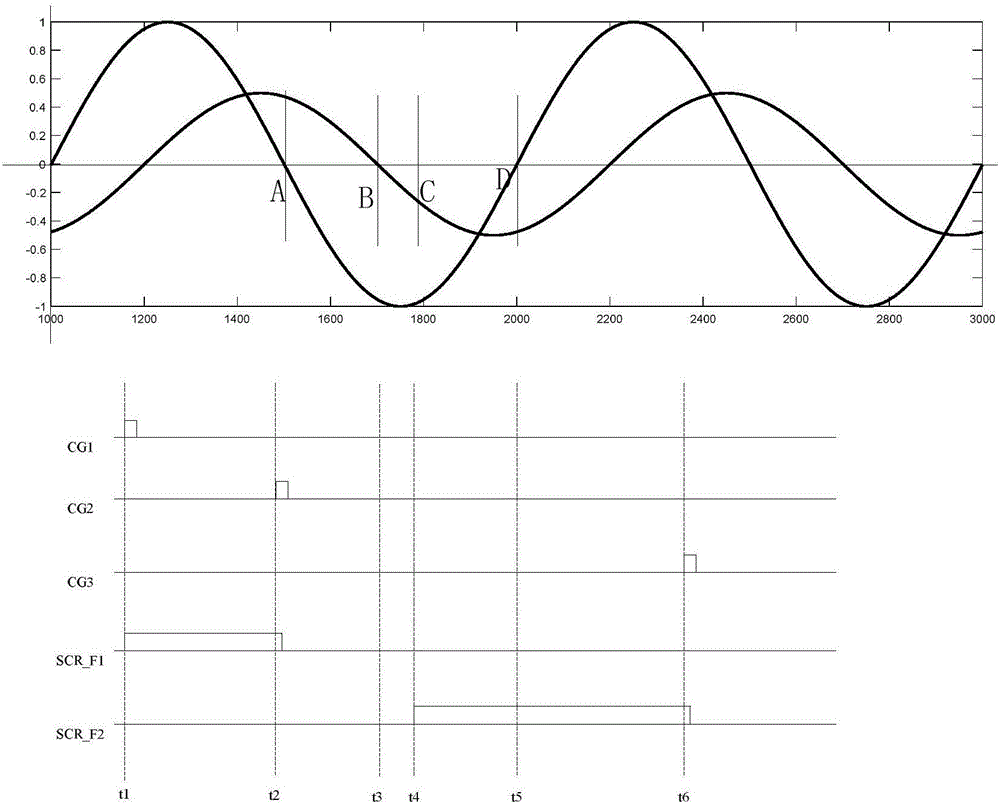

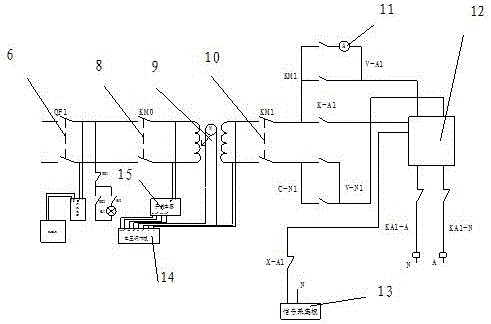

Ground automatic neutral-section passing device and control method thereof

ActiveCN106394318AComplete protection functionsImprove reliabilityPower supply linesThyratronEngineering

The invention discloses a ground automatic neutral-section passing device and a control method thereof. The ground automatic neutral-section passing device comprises a train identification unit, a logic control system, a valve control unit, a thyristor valve block unit consisting of two thyristor valve blocks connected in series, and a current detection unit for detecting the current of the thyristor valve blocks, which are connected successively, wherein the thyristor valve block unit is connected with a two-phase power supply arm and a neutral zone of a catenary respectively; the logic control system is connected to one of the thyristor valve blocks according to an identified train travelling position and direction control to supply power for the neutral zone; and when phase change is needed, the logic control system is connected to the other thyristor valve block according to the state switching of thyristor current. According to the control method, neutral-section passing is realized through controlling the two thyristor valve blocks, and when the phase change is performed, if the current of one of the thyristor valve blocks achieves a cross-zero state through detection and judgment, the other thyristor valve block is opened immediately. The ground automatic neutral-section passing device and the control method disclosed by the invention have the advantages of being capable of realizing automatic neutral-section passing of a train under a condition that the power is not cut off, high in reliability, stable in operation, extremely small in power-off dead zone of the neutral zone, and the like.

Owner:ZHUZHOU NAT ENG RES CENT OF CONVERTERS

Chip-based advanced modulation format transmitter

ActiveUS8401399B2Reduce mold sizeReduced footprintWavelength-division multiplex systemsElectromagnetic transmittersPhase modulationLaser source

In various embodiments, a monolithic integrated transmitter, comprising an on-chip laser source and a modulator structure capable of generating advanced modulation format signals based on amplitude and phase modulation are described.

Owner:FREEDOM PHOTONICS LLC

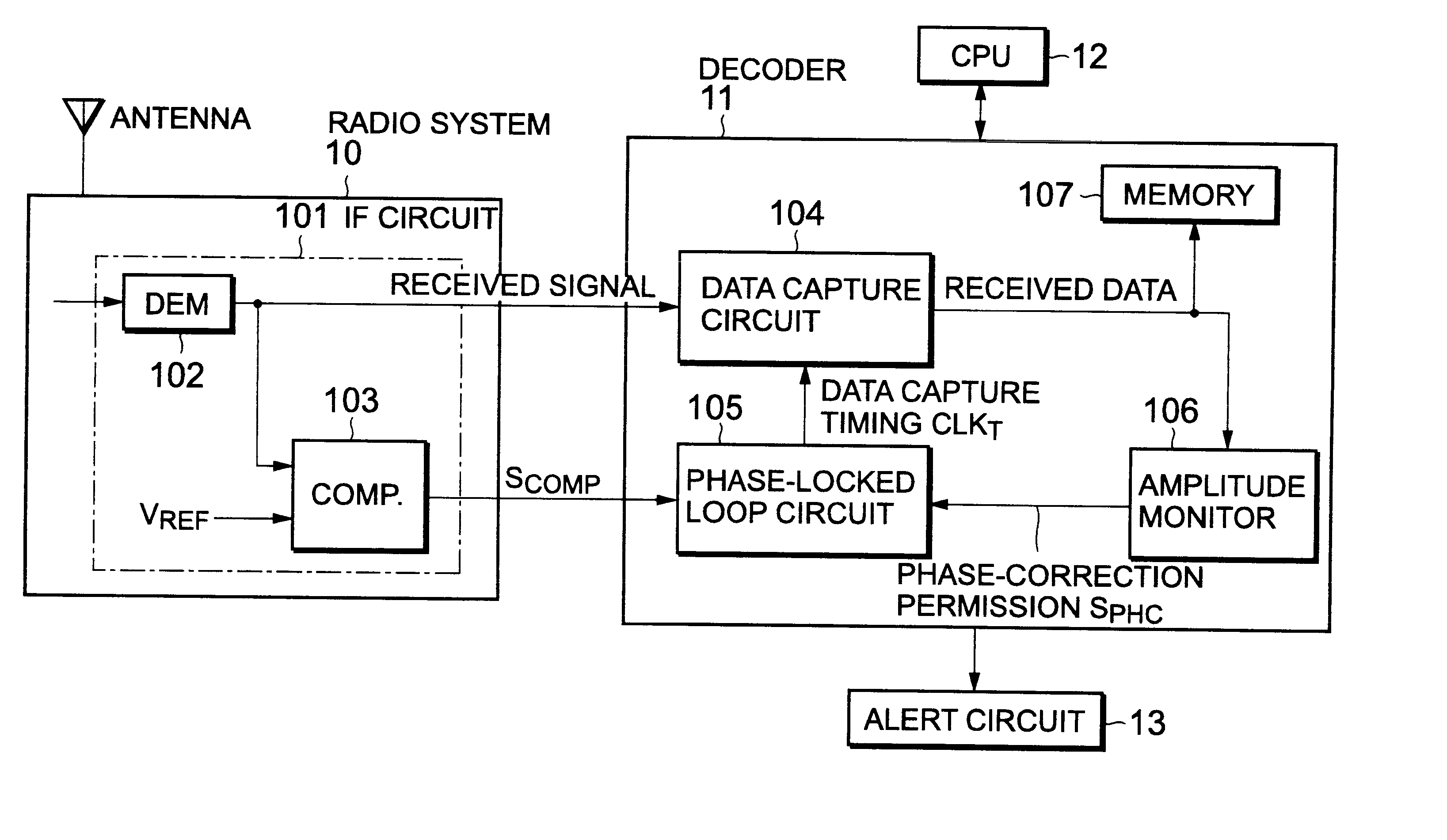

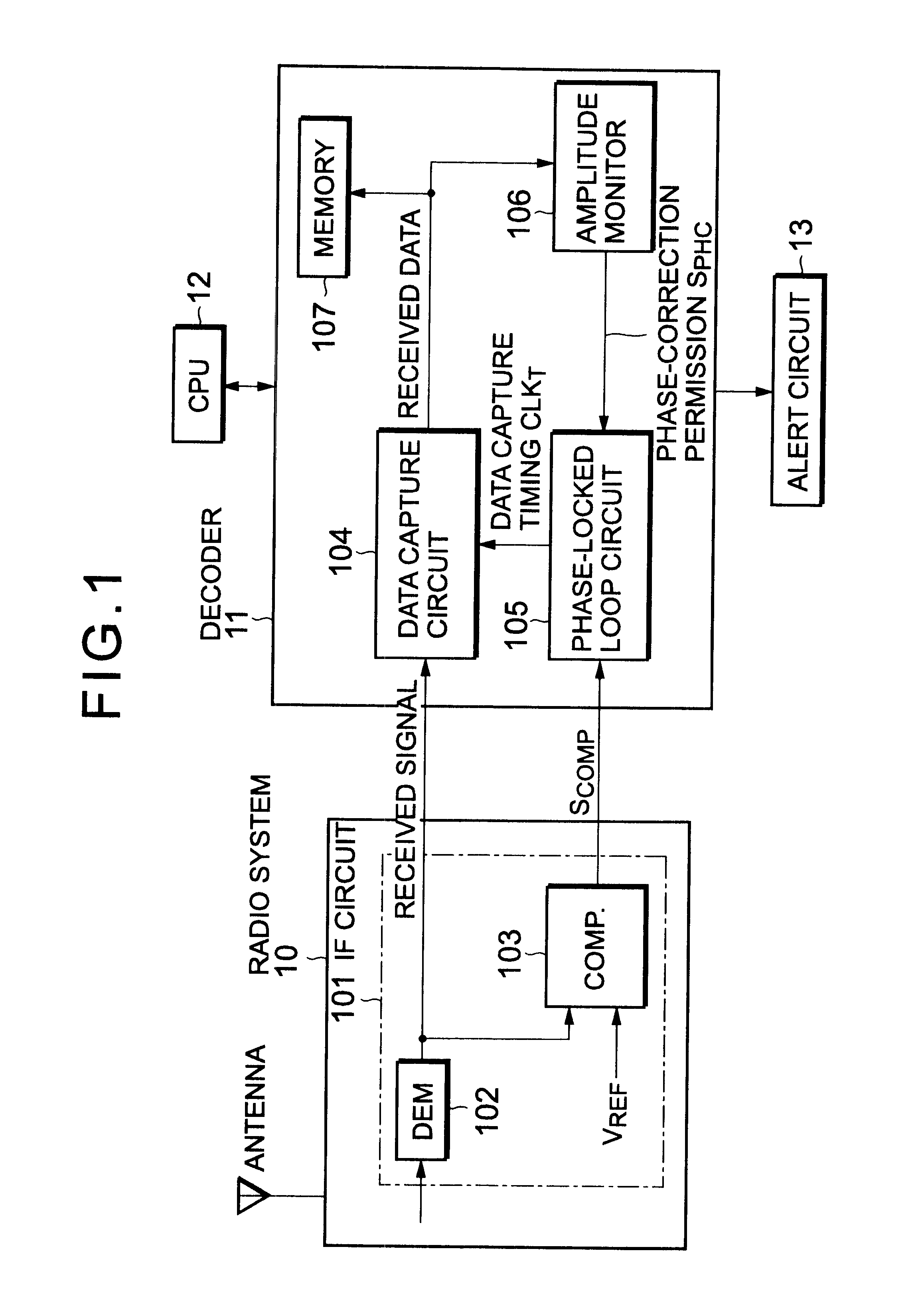

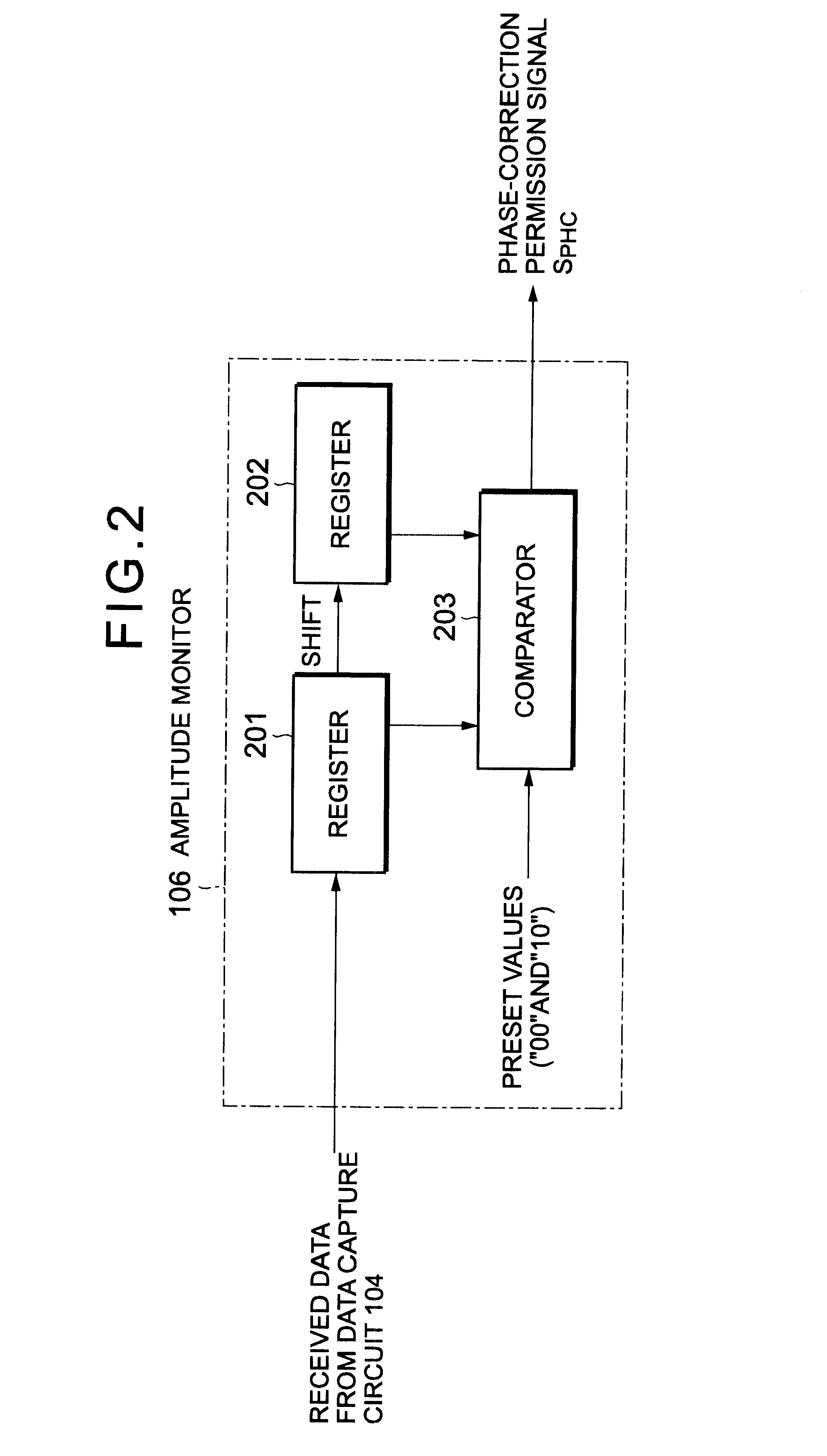

Amplitude change time activated phase locked controller in a selective call receiver

InactiveUS6456831B1Improve accuracyImprove reception accuracySynchronisation arrangementPulse automatic controlSelective callingRadio reception

A radio receiver with improved accuracy of phase-locked loop is disclosed. In addition to a detector for detecting a detected signal from a received radio signal, the receiver includes a monitor for monitoring an amplitude change of the detected signal to detect timing where the amplitude change occurs over a predetermined range. The phase-locked control of the timing clock signal with respect to the detected signal is performed only when the timing is detected by the monitor.

Owner:NEC CORP

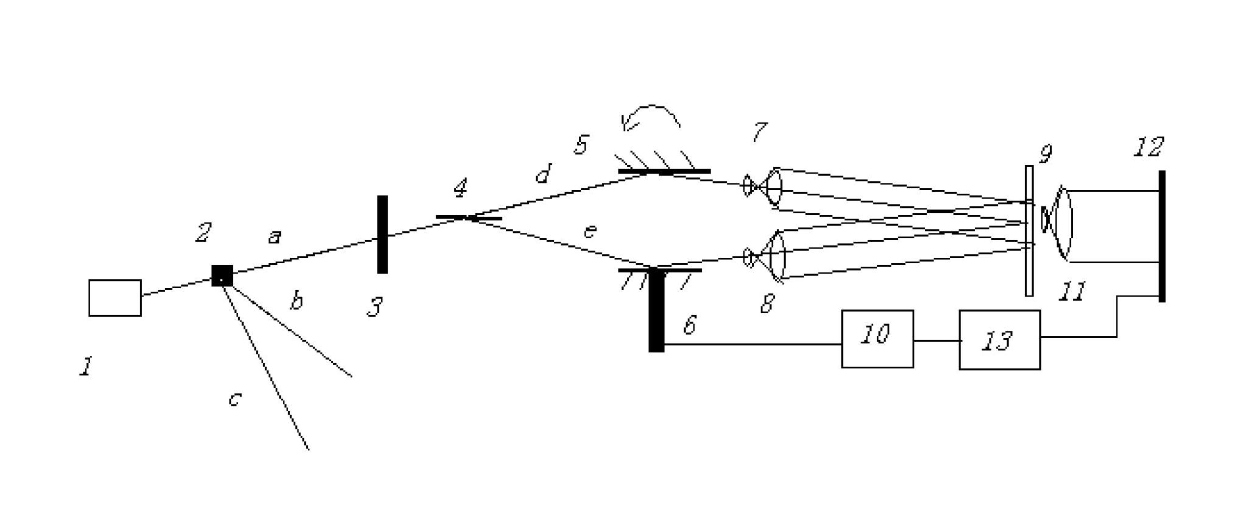

Holographic exposure device of any groove grating structure and exposure method thereof

InactiveCN102636968AAvoid jitter effectsAchieve superimposed effectDiffraction gratingsPhotomechanical exposure apparatusGratingBeam splitter

The invention discloses a holographic exposure device of any groove grating structure and an exposure method thereof. The device comprises a laser and a main beam splitter, wherein a beam emitted by the laser is divided into a plurality of beams of light paths through the main beam splitter; each beam of light path passes through a sub-exposure unit; and the sub-exposure unit comprises an adjustable optical attenuator, a beam splitter, a first reflector, a second reflector, a first collimating beam expander, a second collimating beam expander, a rotary platform, piezoelectric ceramic and a driver, a microscope objective set, a CCD (Charge Coupled Device) receiver and a driving circuit, a data acquisition card and a computer. According to the holographic exposure device and the exposure method thereof, holographic manufacturing of any groove grating can be realized by using the idea of Fourier decomposition. A CCD is arranged in the device, so that a vibration drift condition of an interference fringe can be reflected in real time, the piezoelectric ceramic is driven thereby, the locking of the interference fringe is realized, the influence of fringe jitter on long-term exposure is avoided, meanwhile, the phase of each group of interference fringes is accurately controlled according to information on the interference fringes after beam expansion, and matching and superposing of a plurality of groups of interference fringes are realized.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

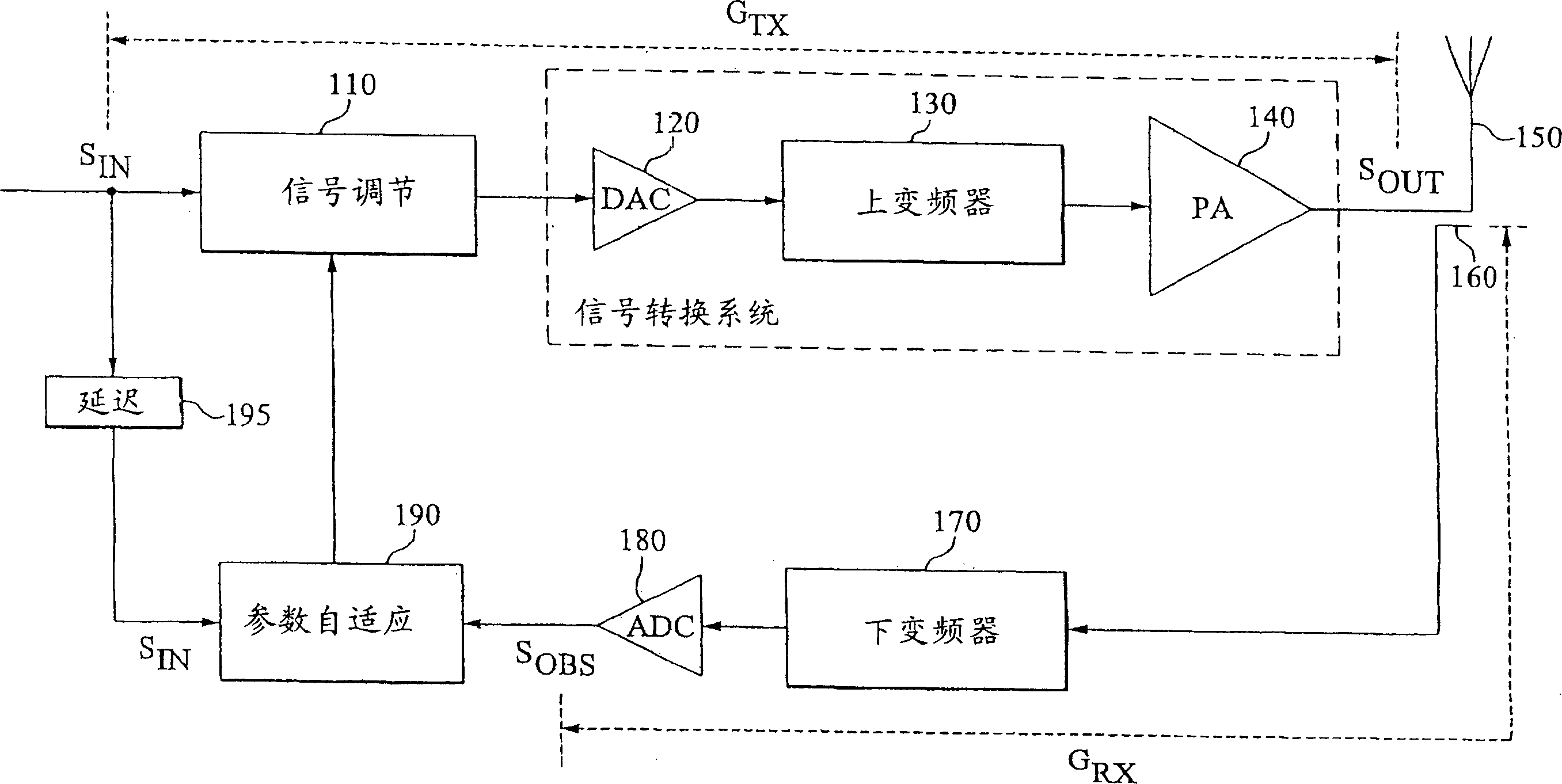

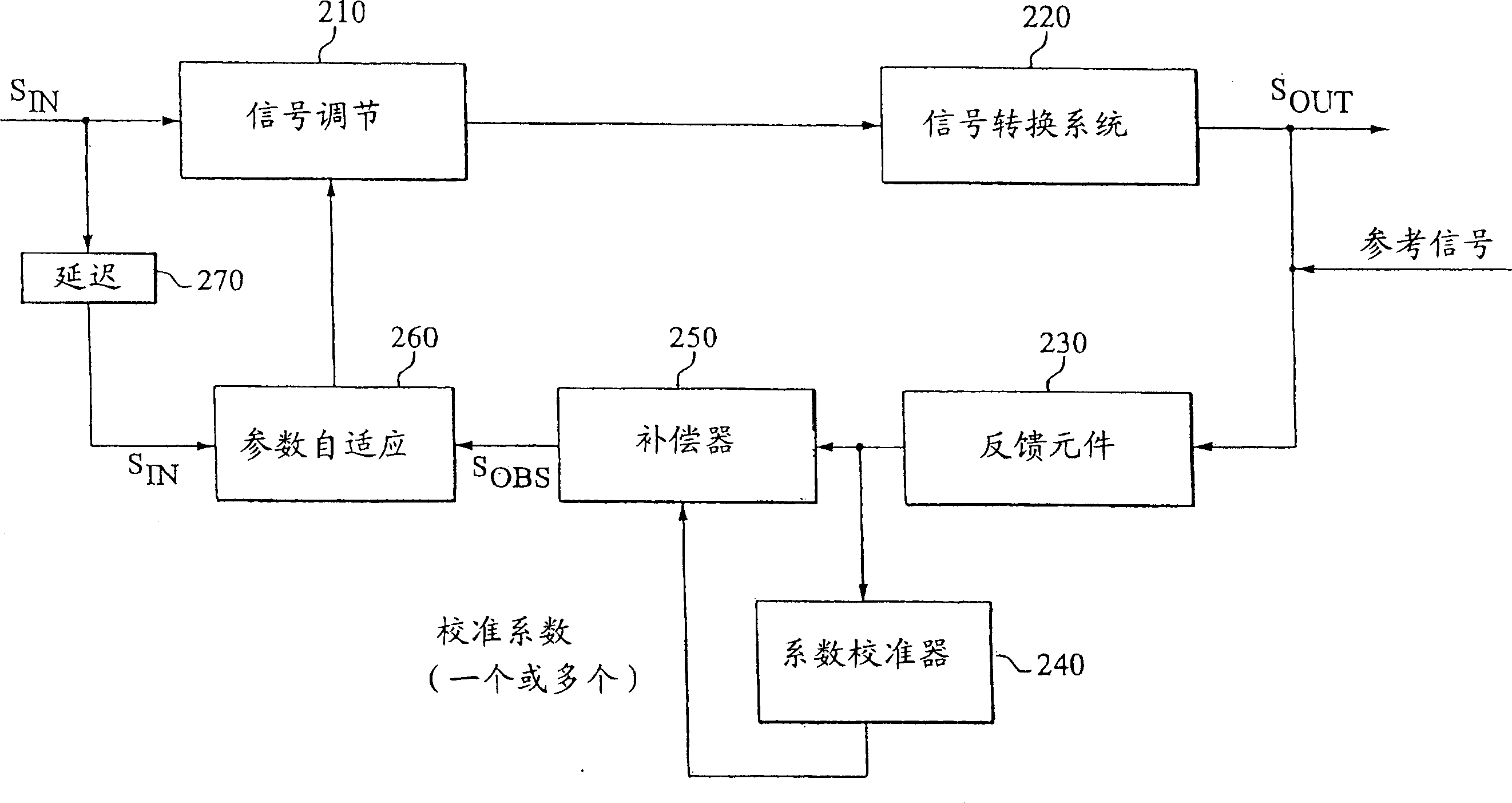

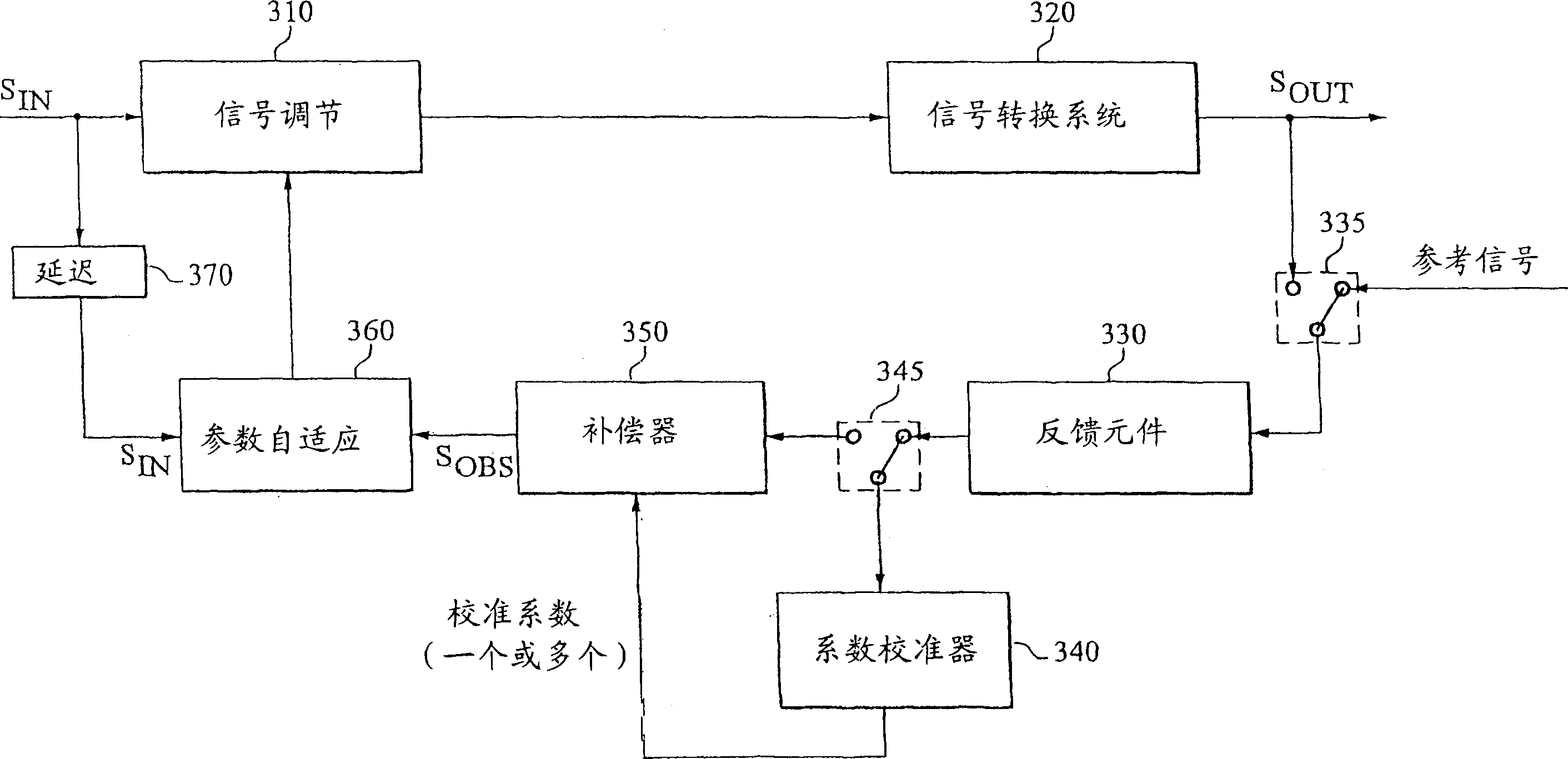

Calibration of an adaptive signal conditioning system

InactiveCN1550064AReliable calibrationWithout disrupting normal operationAmplifier modifications to reduce non-linear distortionSignal conditioningEngineering

The invention provides robust and non-invasive calibration of an adaptive signal conditioning system having a signal conditioning block in the signal path to a signal conversion system, and a feedback path with a number of feedback components for enabling adaptation, by means of a parameter adaptation block, of the parameters used in the signal conditioning. In order to calibrate the feedback path, a well-defined reference signal is inserted into the feedback path, and an appropriate calibration coefficient is then determined by a coefficient calibrator in response to the received reference signal. The calibration coefficient is provided to a compensator, which effectively compensates for changes in the transfer characteristics of the feedback path due to factors such as variations in ambient temperature and component aging. Accordingly, the feedback signal transferred over the calibrated feedback path will be an accurate representation of the output signal of the signal conversion system, thus allowing accurate adaptive signal conditioning.

Owner:TELEFON AB LM ERICSSON (PUBL)

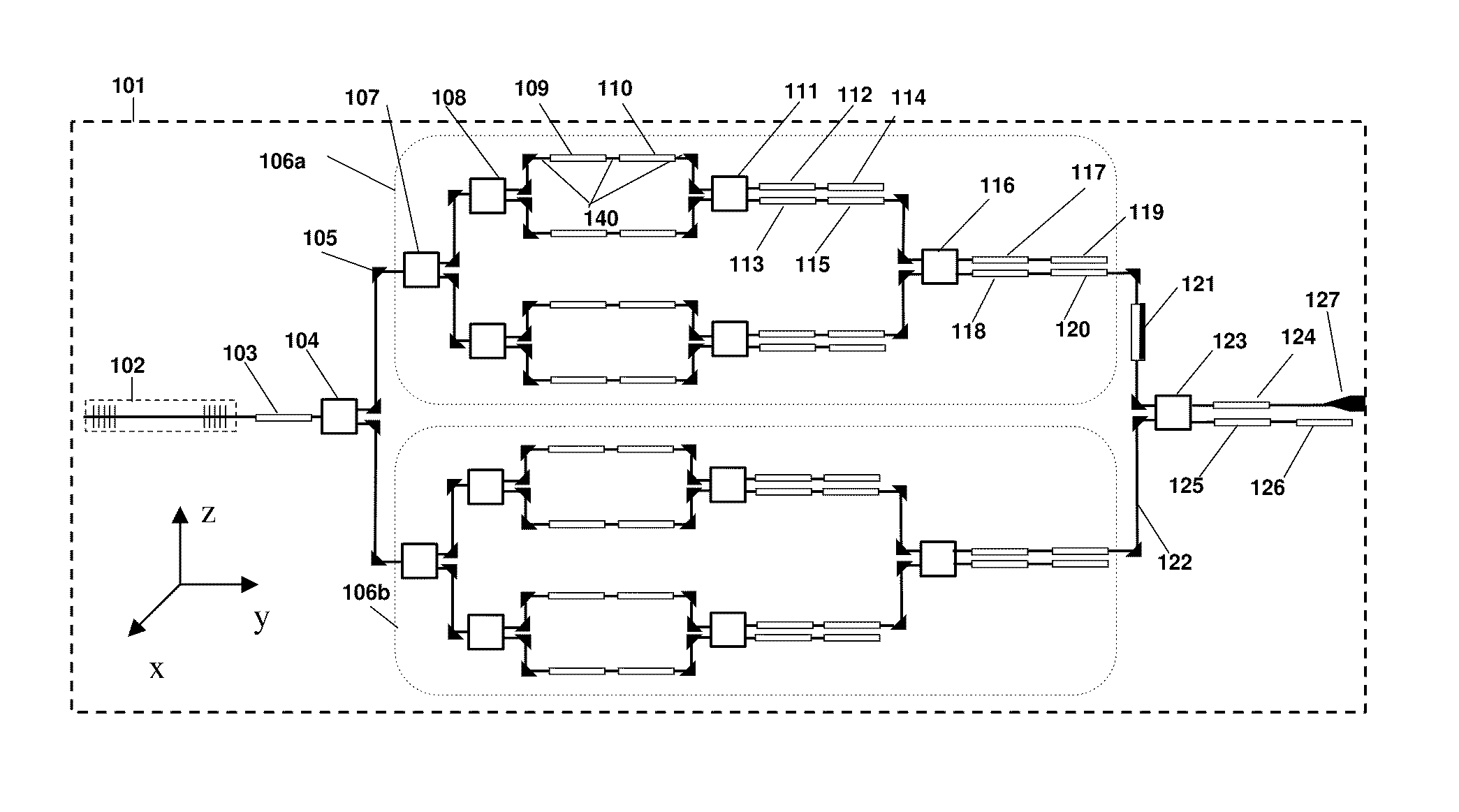

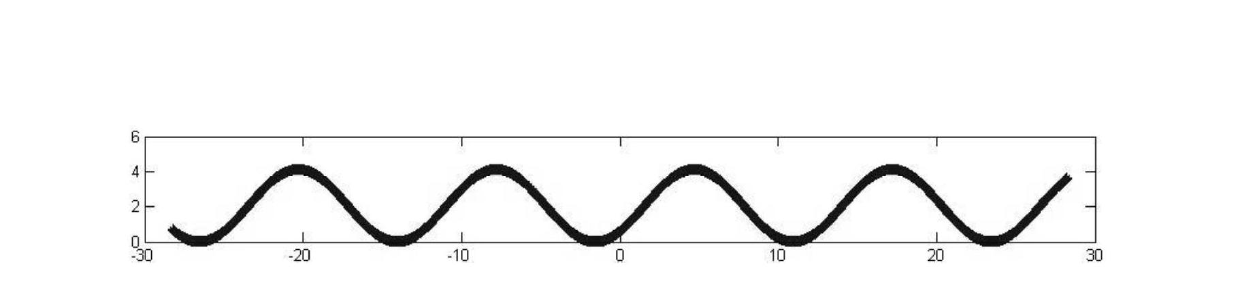

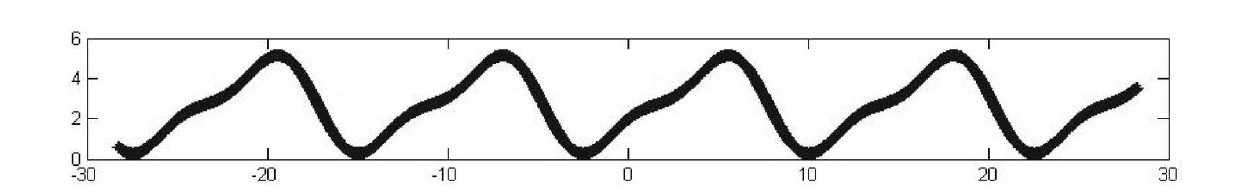

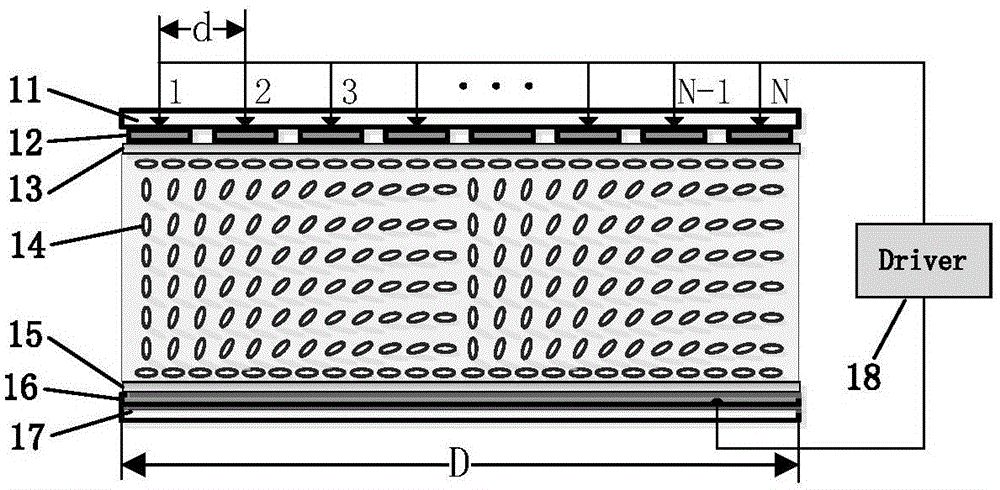

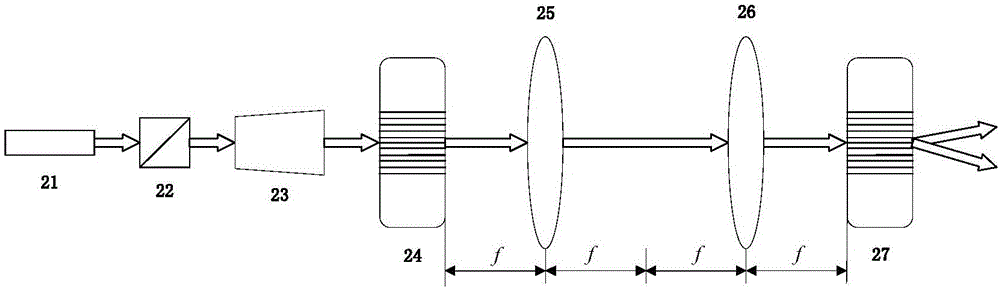

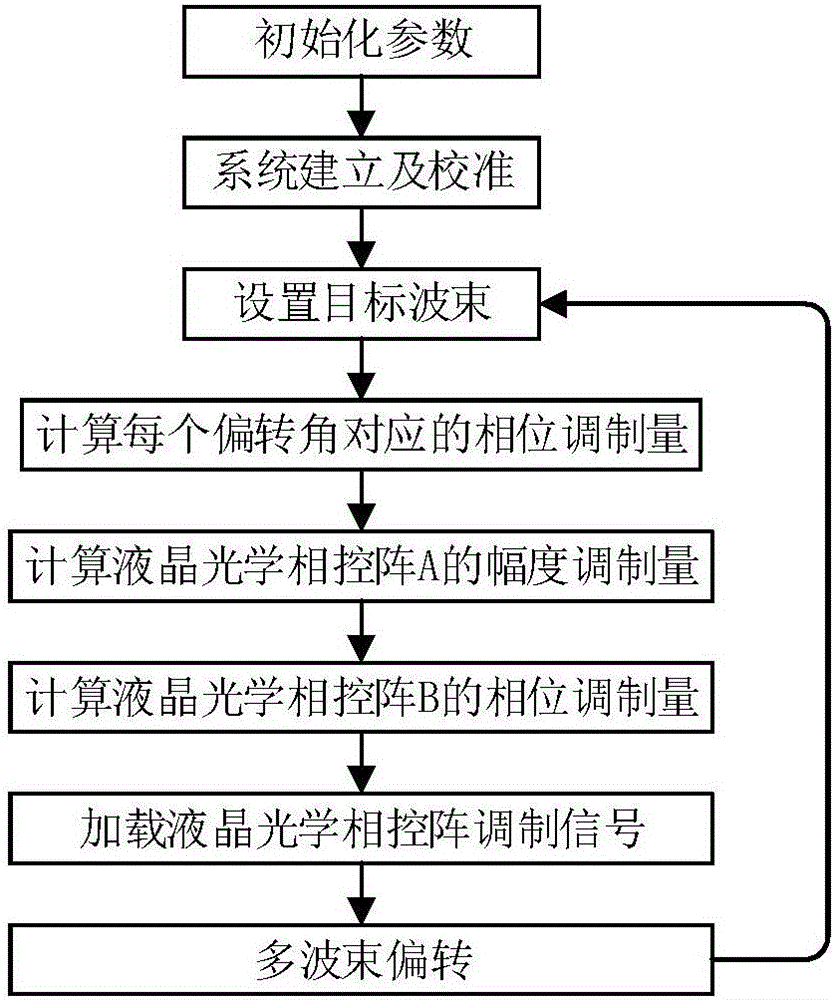

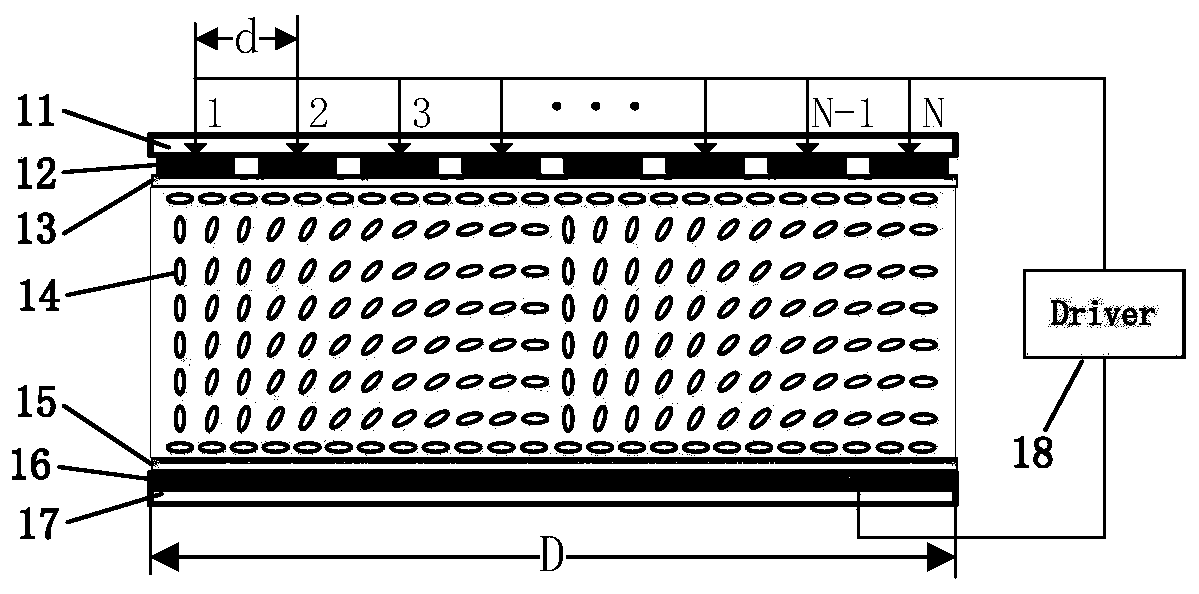

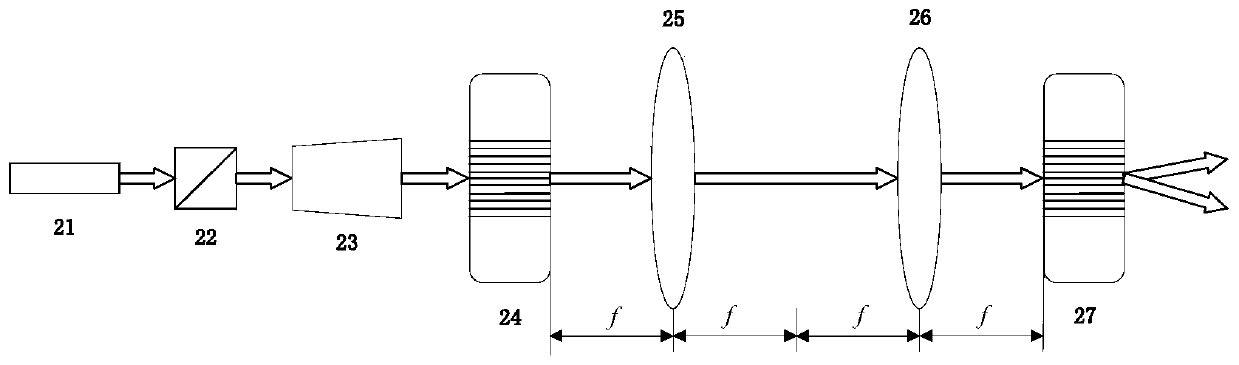

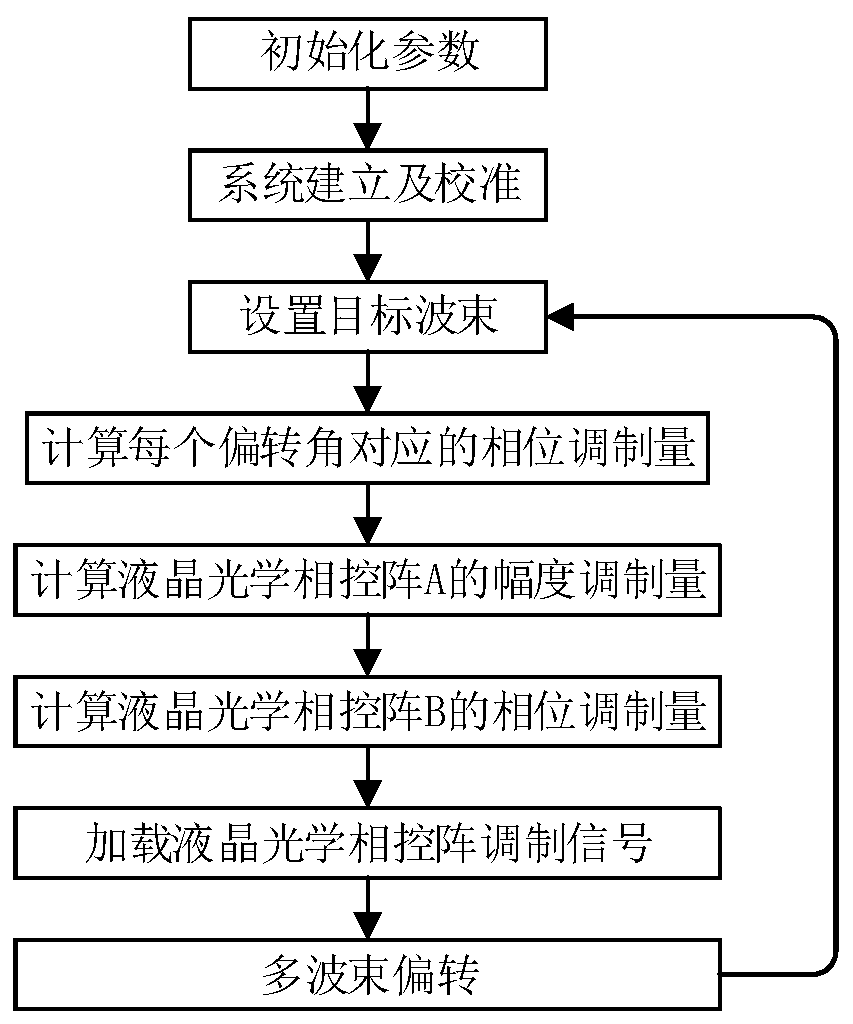

Laser phased array multi-beam forming system and method

InactiveCN106154681APrecise Amplitude and Phase ControlEnables multiple beamforming and deflectionNon-linear opticsLiquid crystalPrism

The invention discloses a laser phased array multi-beam forming system and method. The system specifically comprises a laser, a polarization splitting prism, a beam expander, a first liquid crystal optical phased array, a 4f optical system and a second liquid crystal optical phased array. An outgoing laser beam of the laser sequentially passes through the polarization splitting prism, the beam expander, the first liquid crystal optical phased array, the 4f optical system and the second liquid crystal optical phased array; the mode of cascading the two liquid crystal optical phased arrays is adopted for achieving forming and deflection of any multi-beam, one phased array is adopted as an amplitude modulator, the other phased array is adopted as a phase modulator, and the 4f system is used for precisely aligning phase shifting units of the two phased arrays. The mode of precise control over the amplitudes of the liquid crystal optical phased arrays and phase modulation is adopted, and forming and random pointing of any number of wave beams can be achieved.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

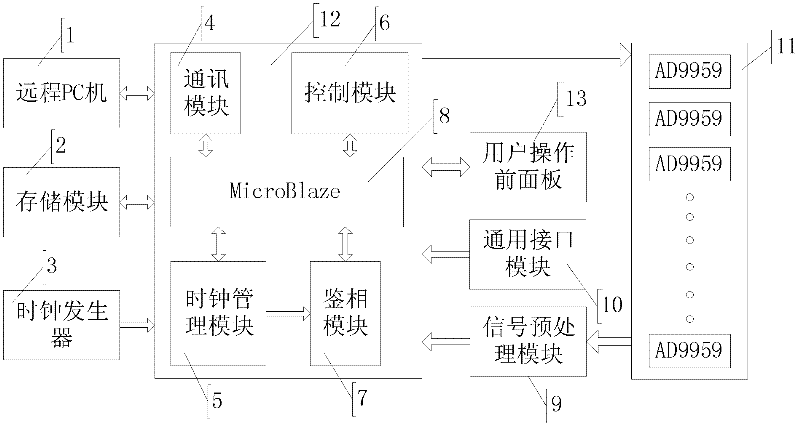

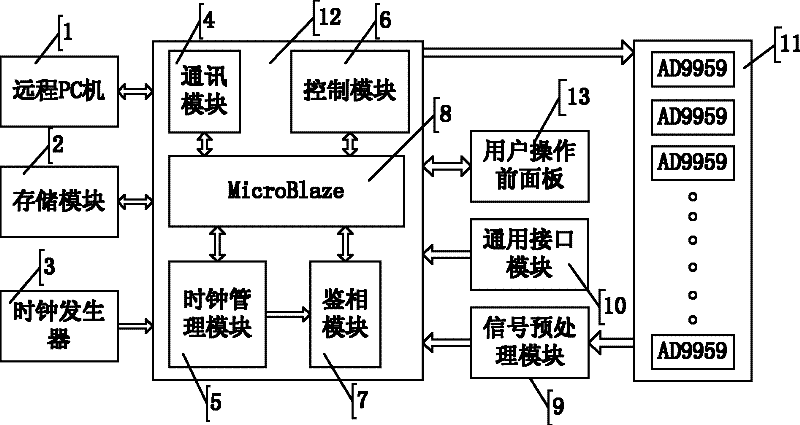

Multi-channel synchronizing signal generator based on field program gate array (FPGA) and AD9959

InactiveCN102354256APrecise phase controlNumber of expansion channelsGenerating/distributing signalsClock generatorGate array

The invention relates to a multi-channel synchronizing signal generator based on field program gate array (FPGA) and an AD9959. The multi-channel synchronizing signal generator comprises a remote personal computer (PC) (1), a storage module (2), a clock generator (3), an FPGA chip (12), a signal preprocessing module (9), a universal interface module (10), a digital frequency generation module (11) and a user-operated front panel (13), wherein the FPGA chip (12) is respectively connected with the remote PC (1), the storage module (2), the clock generator (3), the signal preprocessing module (9), the universal interface module (10), the digital frequency generation module (11) and the user-operated front panel (13); and the signal preprocessing module (9) is connected with the digital frequency generation module (11). Compared with the prior art, the multi-channel synchronizing signal generator has the advantages of simple circuit structure, high application value and the like.

Owner:SHANGHAI JIAO TONG UNIV

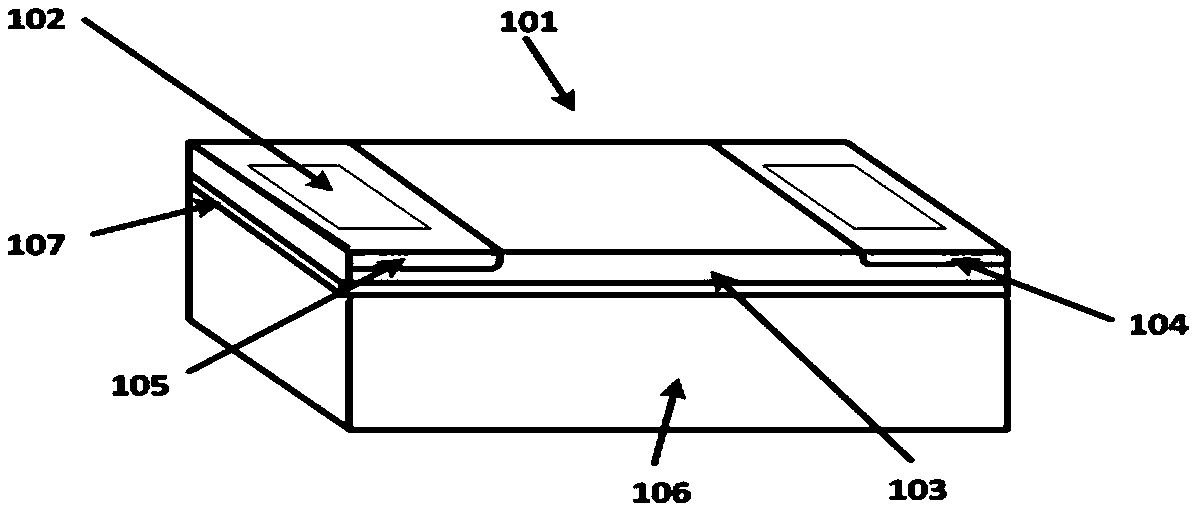

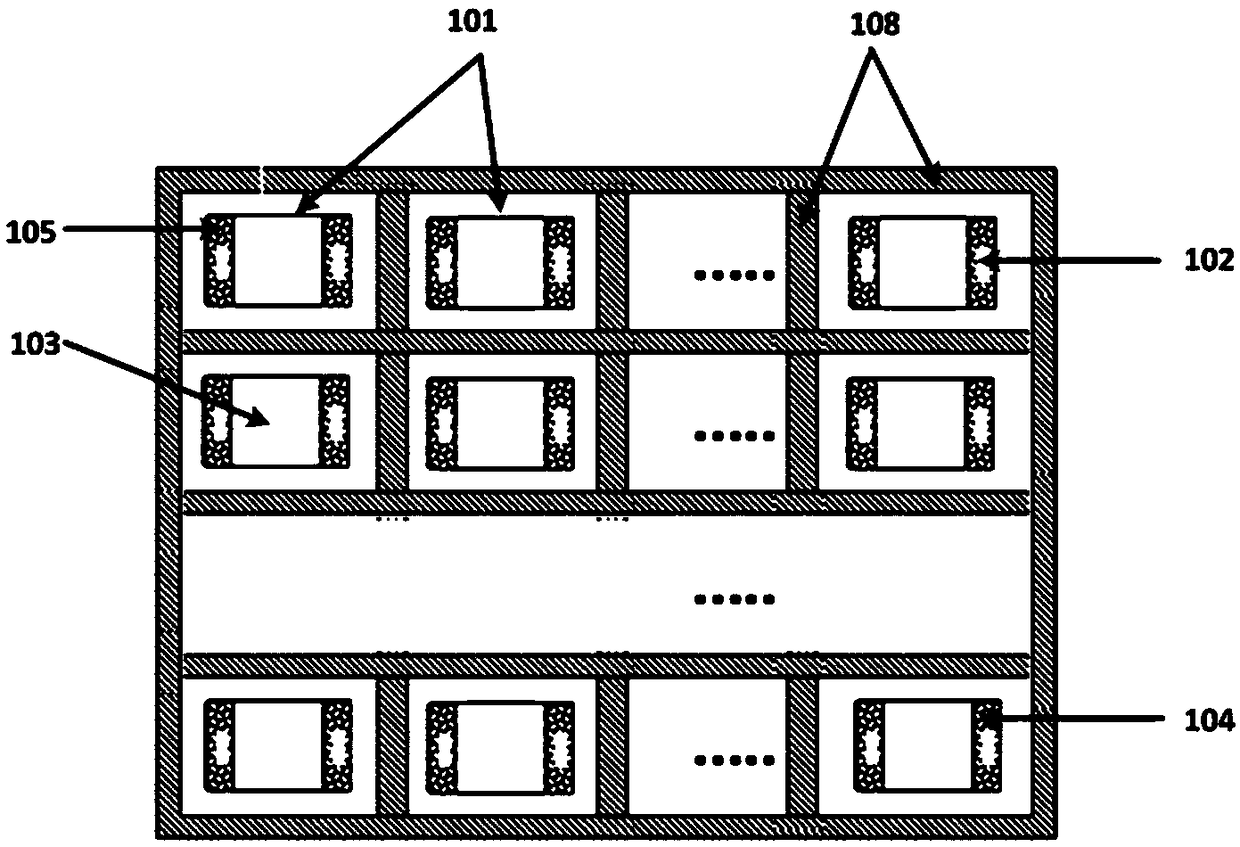

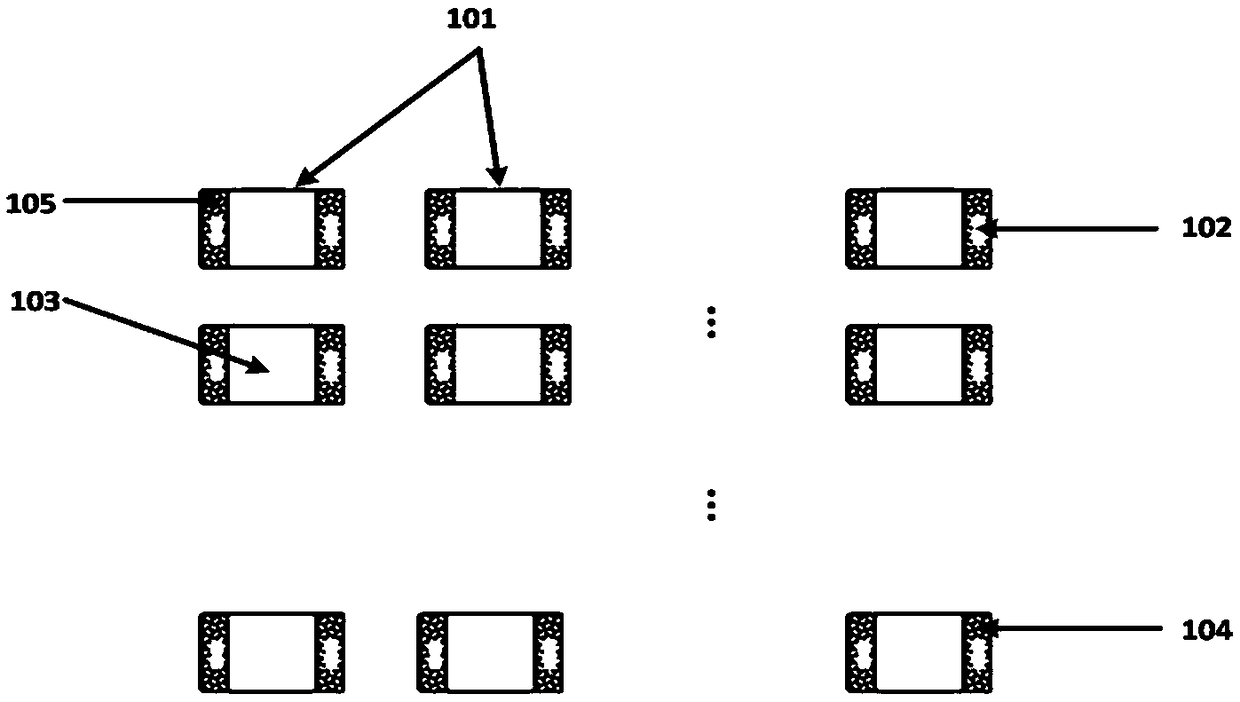

Reconfigurable multi-functional antenna based on distributed direct drive arrays

PendingCN108767445AChange shapeShort switching timeAntenna arraysRadiating elements structural formsDielectric substrateEngineering

The invention mainly belongs to the technical field of antennas and relates to a fast agile multi-functional planar and quasi-three-dimensional antenna, in particular to a reconfigurable multi-functional antenna. The multi-function antenna is composed of the semiconductor plasma and the fast, large current, simple TFT matrix driving technology distributed direct drive arrays integrated into silicon, glass, sapphire, silicon carbide and other planar or curved dielectric substrates, the multi-function antenna can quickly, dynamically control the shape, size and the correct position to be in of the radiating elements constituting the planar array, the antenna frequency is reconfigurable, polarization reconfigurability, beam control and gain agility reconfigurability, sidelobe position and relative level reconfigurability, and combinations of these, like a two-dimensional printer, rapidly and agilely change the antenna from one function to another, transforming a planar or quasi-three-dimensional antenna into a multi-function planar or quasi-three-dimensional antenna.

Owner:北京神舟博远科技有限公司

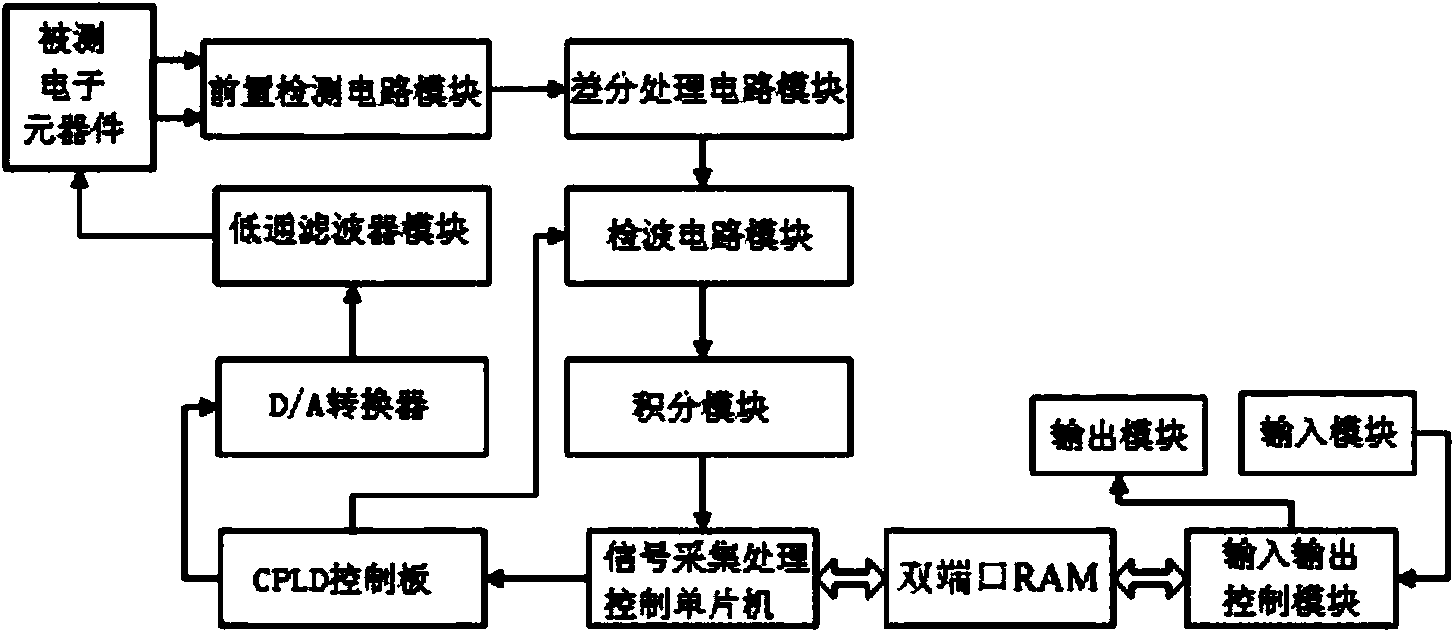

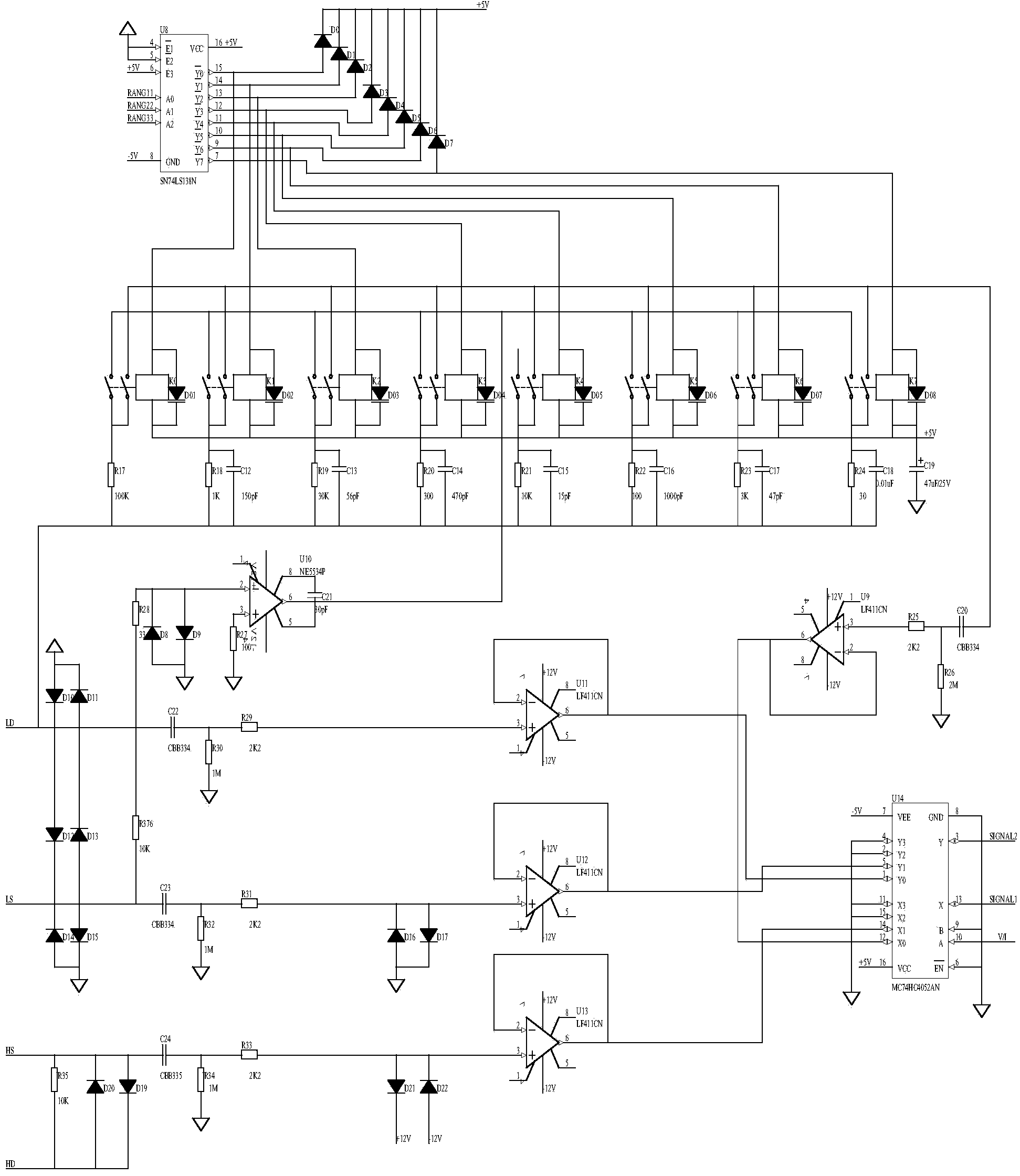

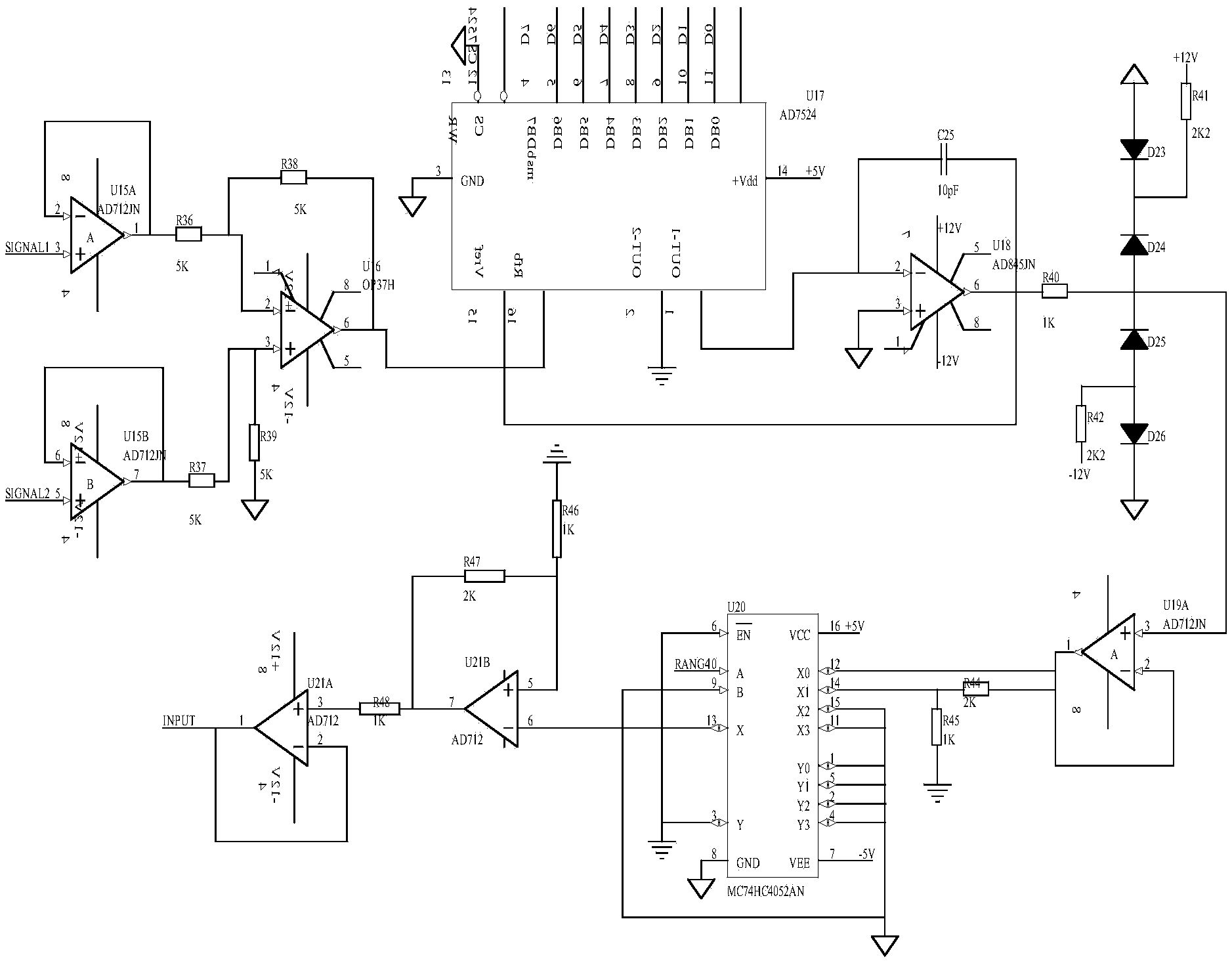

RLC measuring instrument and measuring method

InactiveCN104142430AImprove waveform qualityLarge measuring rangeResistance/reactance/impedencePhase noiseMeasuring instrument

The invention relates to an RLC measuring instrument. The CPLD technology is adopted for replacing a digital circuit to generate sine detection signals, chip resources on a CPLD development board are rich, PLLs are contained in the CPLD development board, and the frequency can be multiplied and divided conveniently. The RLC measuring instrument comprises a storage unit, a ROM table macroblock can be directly called, an SOPC can be used as a kernel, high-frequency test signals can be obtained conveniently, and the waveform quality of the sine detection signals can be improved. The invention further relates to a measuring method based on the RLC measuring instrument. The direct digital frequency synthesis technique is adopted, the frequency and the phase of the output sine detection signals can be accurately controlled, and meanwhile, the measuring instrument has the advantages that frequency switching time is short, the frequency resolution is high, the phase is changed continuously, phase noise and drifting are low, and integration and adjustment are easy.

Owner:YANCHENG INST OF TECH

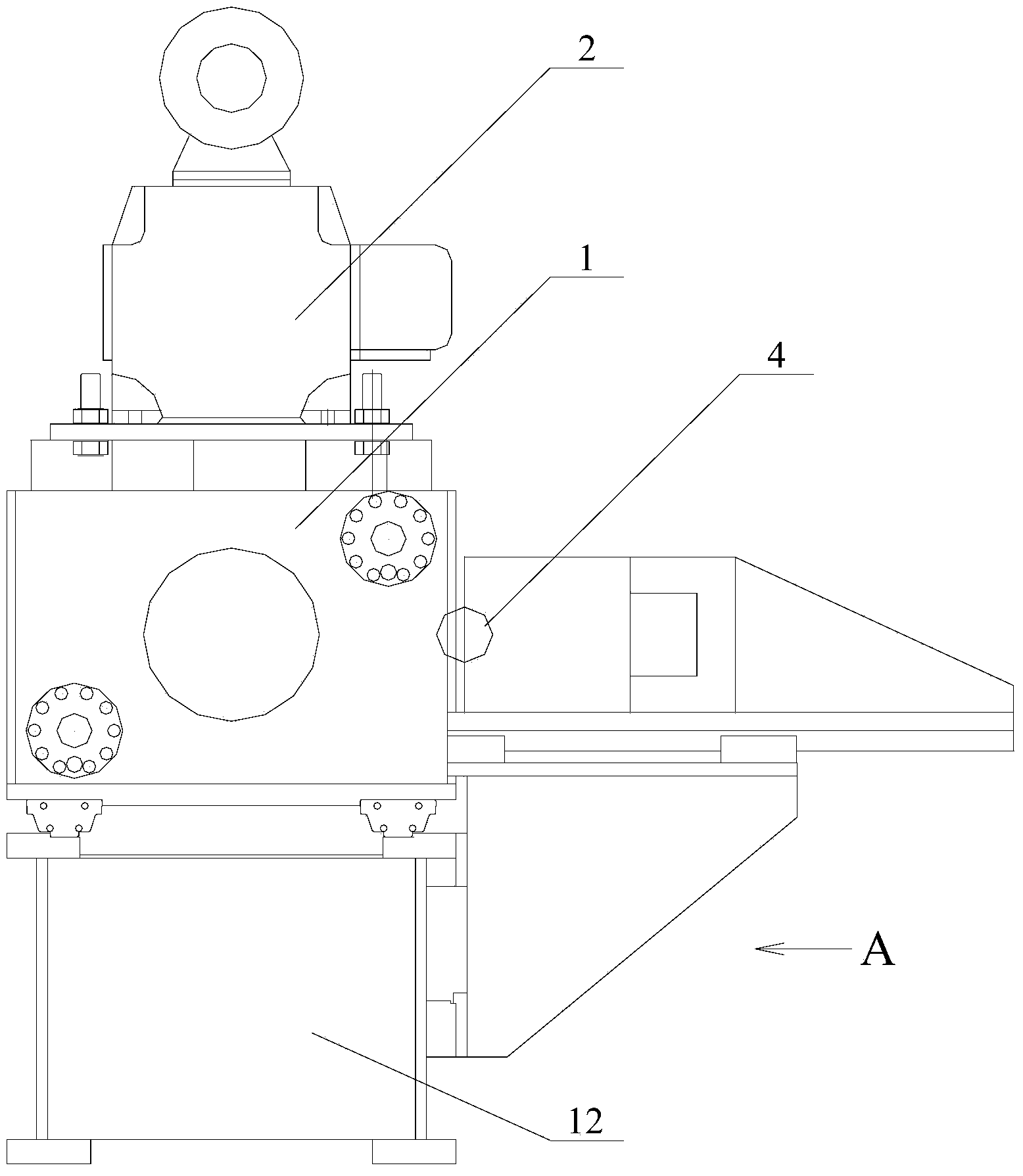

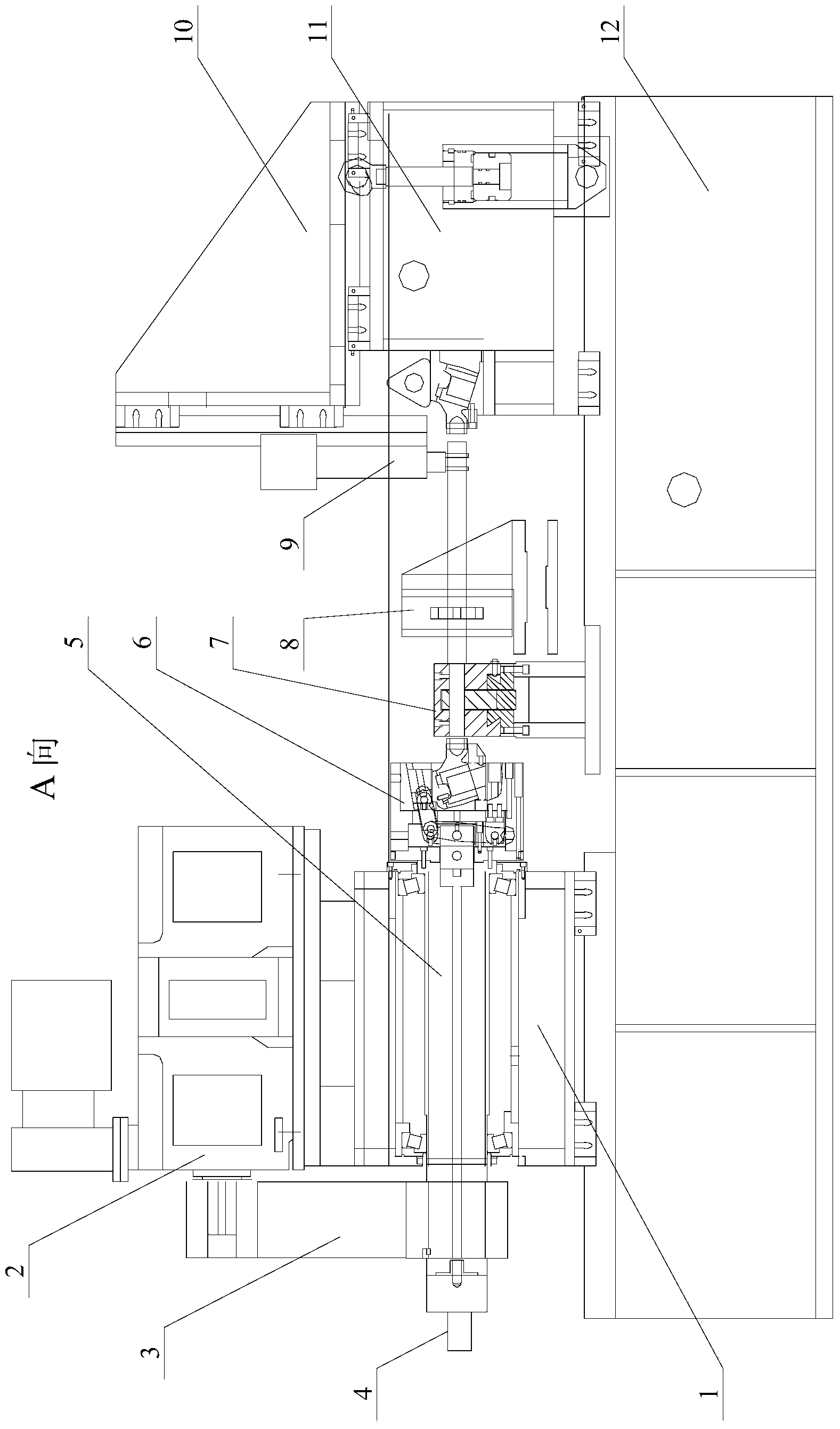

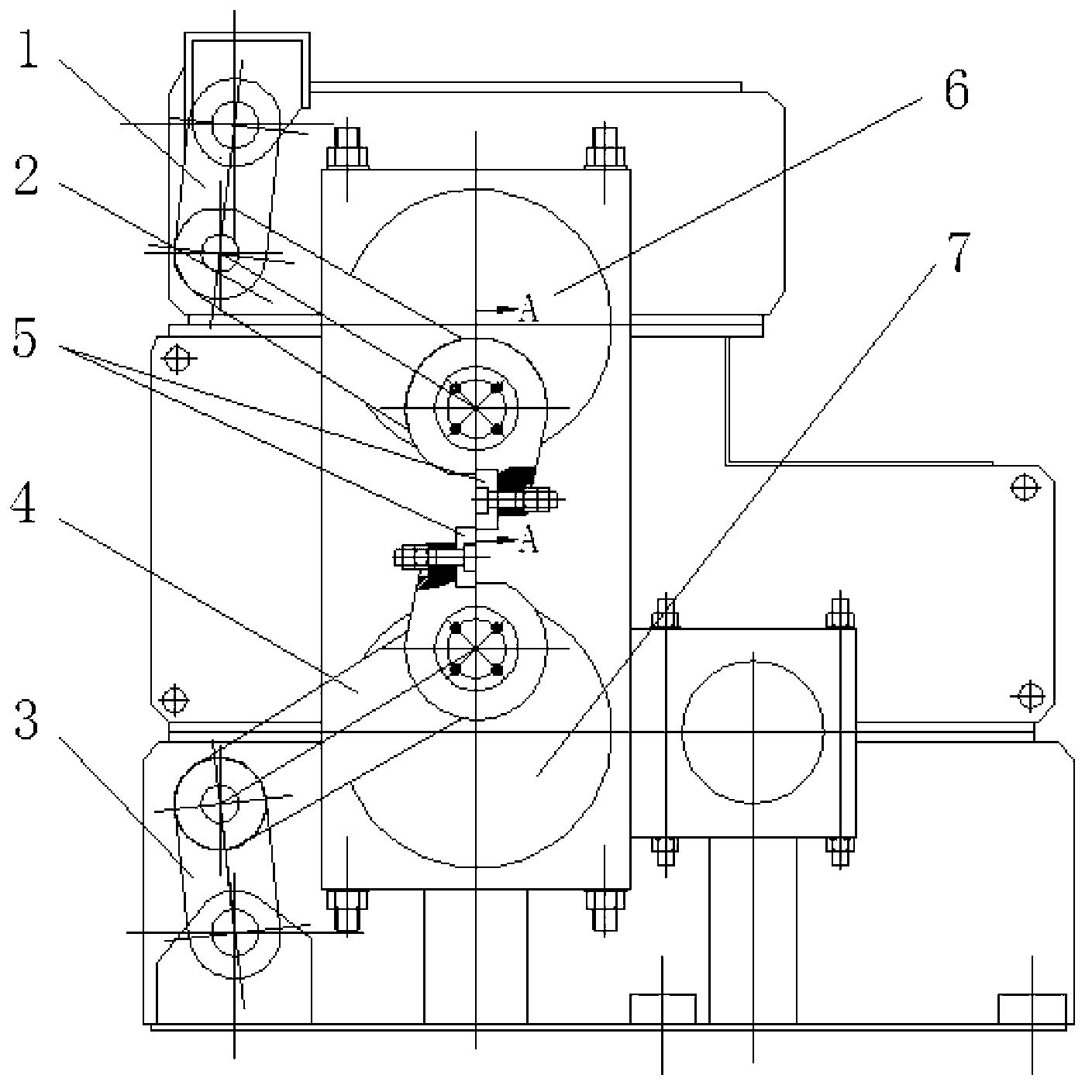

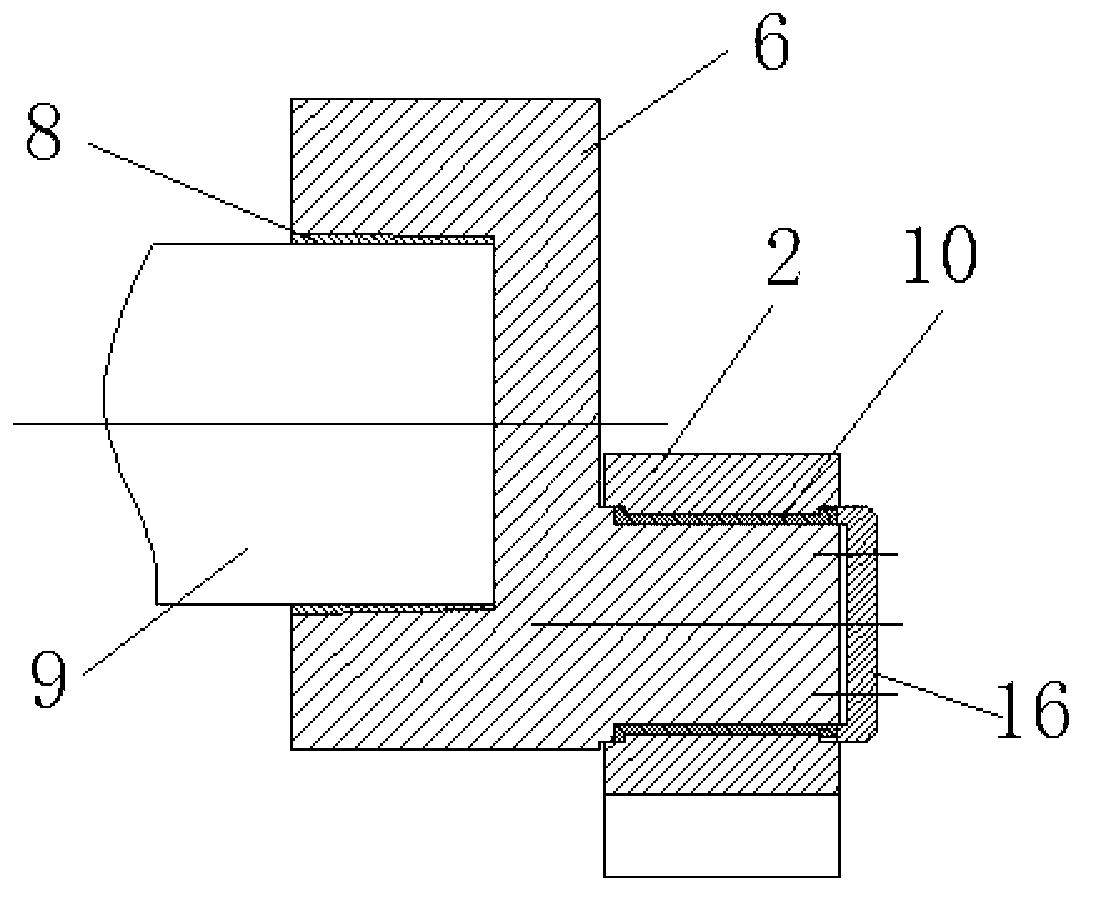

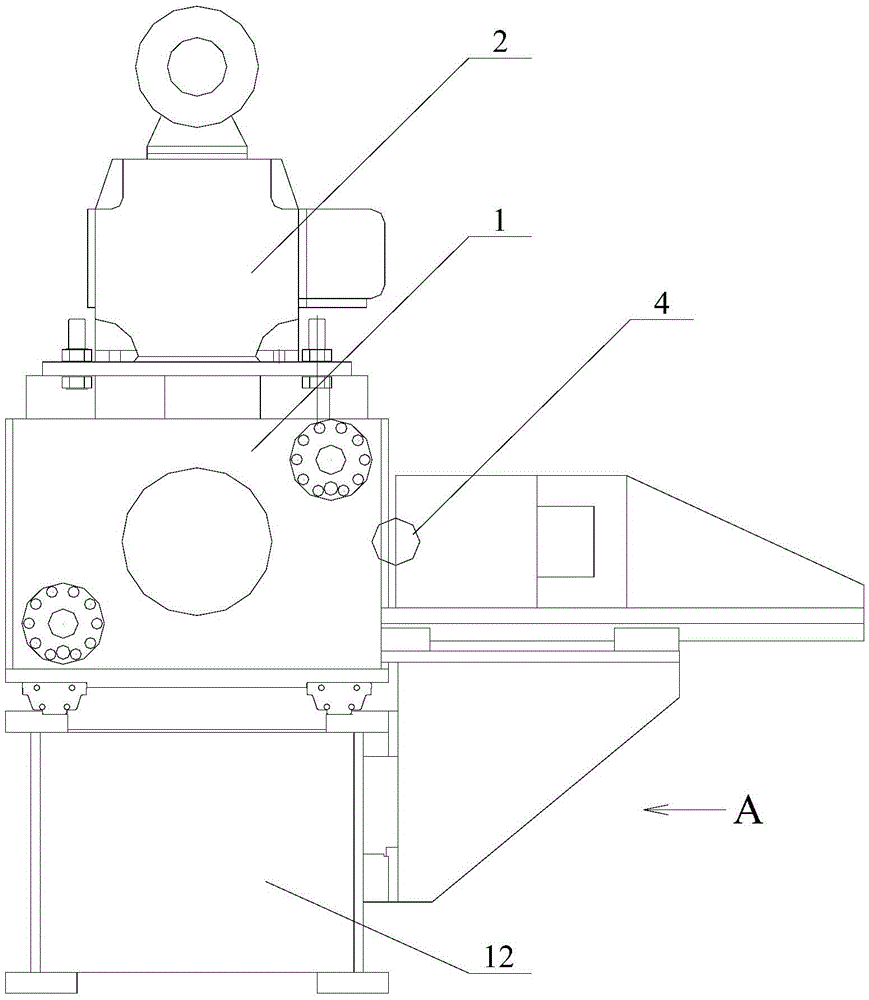

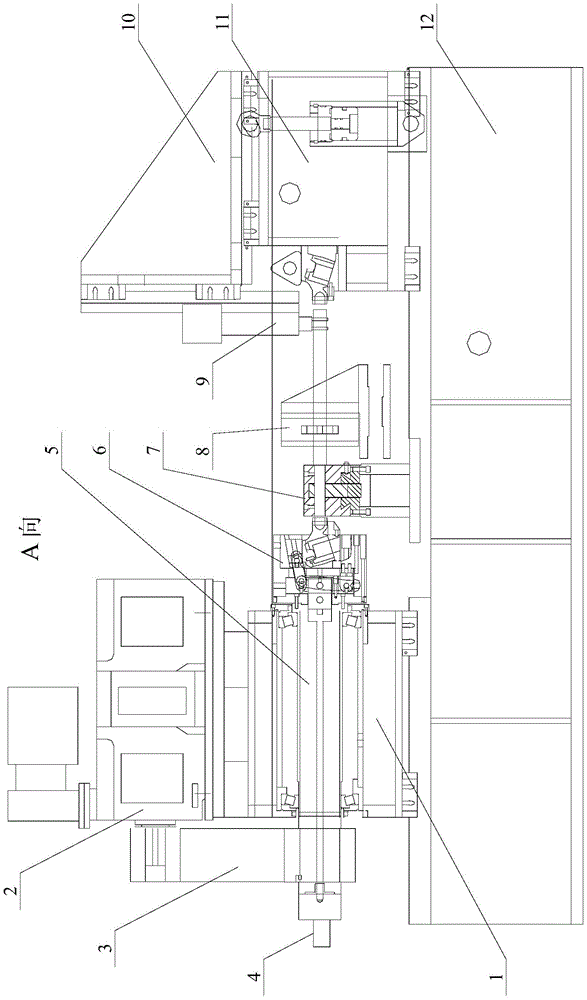

Single-main-shaft box one-time clamping double-end phase friction welder

ActiveCN103521914AAccurate control of angular velocityAccurate control of angular displacementWelding/cutting auxillary devicesAuxillary welding devicesFriction weldingAngular velocity

The invention provides a single-main-shaft box one-time clamping double-end phase friction welder and belongs to the technical field of friction welders. A main shaft box is arranged on the upper portion of one side of a lathe bed. A tool locating clamping device is arranged on the upper portion of the other side of the lathe bed. A back pushing device is arranged on the upper portion of the tool locating clamping device. A main shaft is arranged in the main shaft box. A coding machine is arranged at the outer end of the main shaft. A direct-current motor component is arranged on the upper portion of the main shaft box. The direct-current motor component and the main shaft are in transmission connection through a synchronous pulley transmission mechanism. A rotating clamp is arranged at the inner end of the main shaft. During using, three workpieces are clamped at one time, accuracy loss caused by clamping again in secondary welding in a 180-degree-turning mode is avoided, welding phase accuracy is improved, and meanwhile welding production efficiency is improved. A direct-current motor is used for accurately controlling the angular velocity and the angular displacement of the main shaft, and accurate phase control of welding friction is achieved. The phase control accuracy can reach + / -0.5 degree.

Owner:哈尔滨正晨焊接切割设备制造有限公司

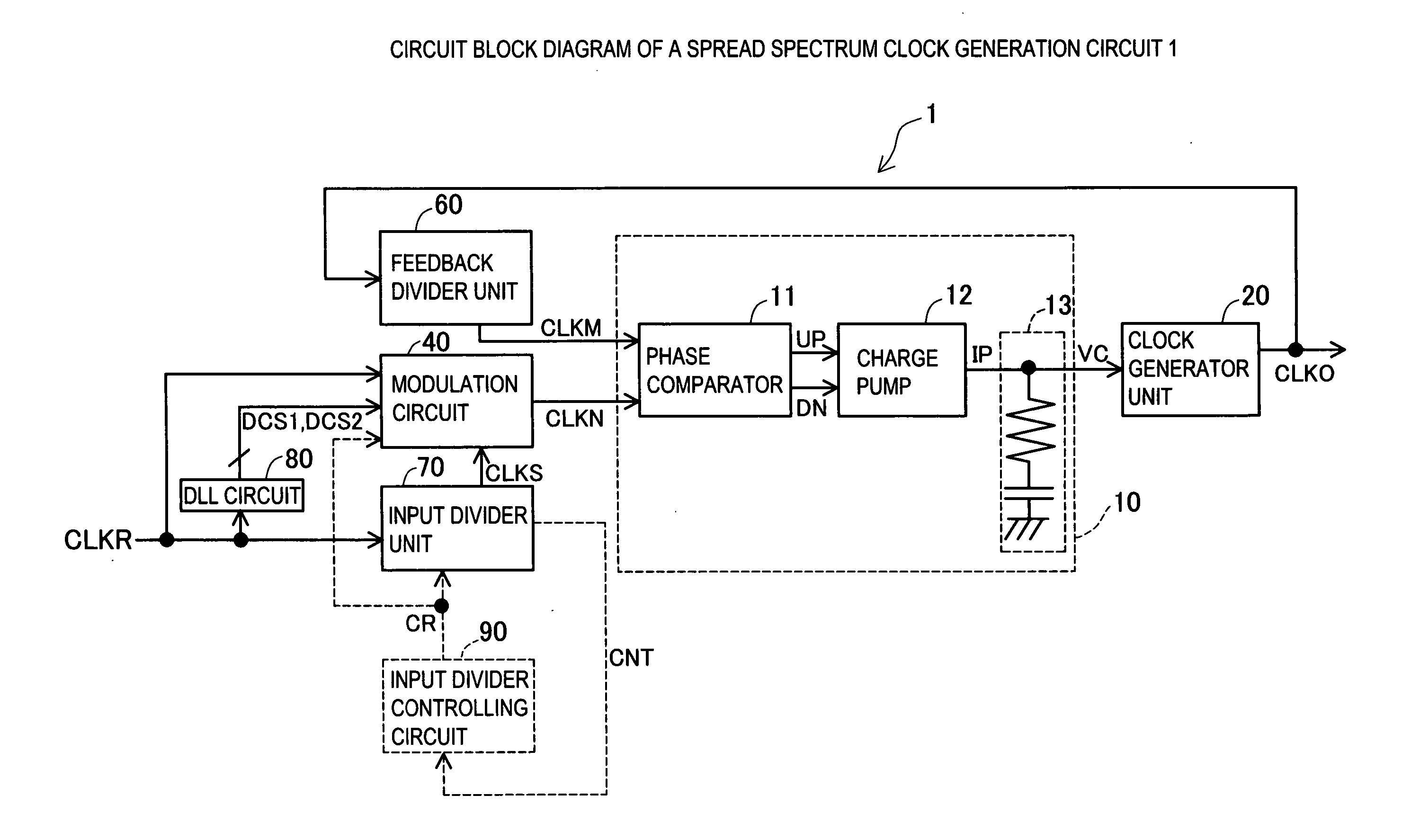

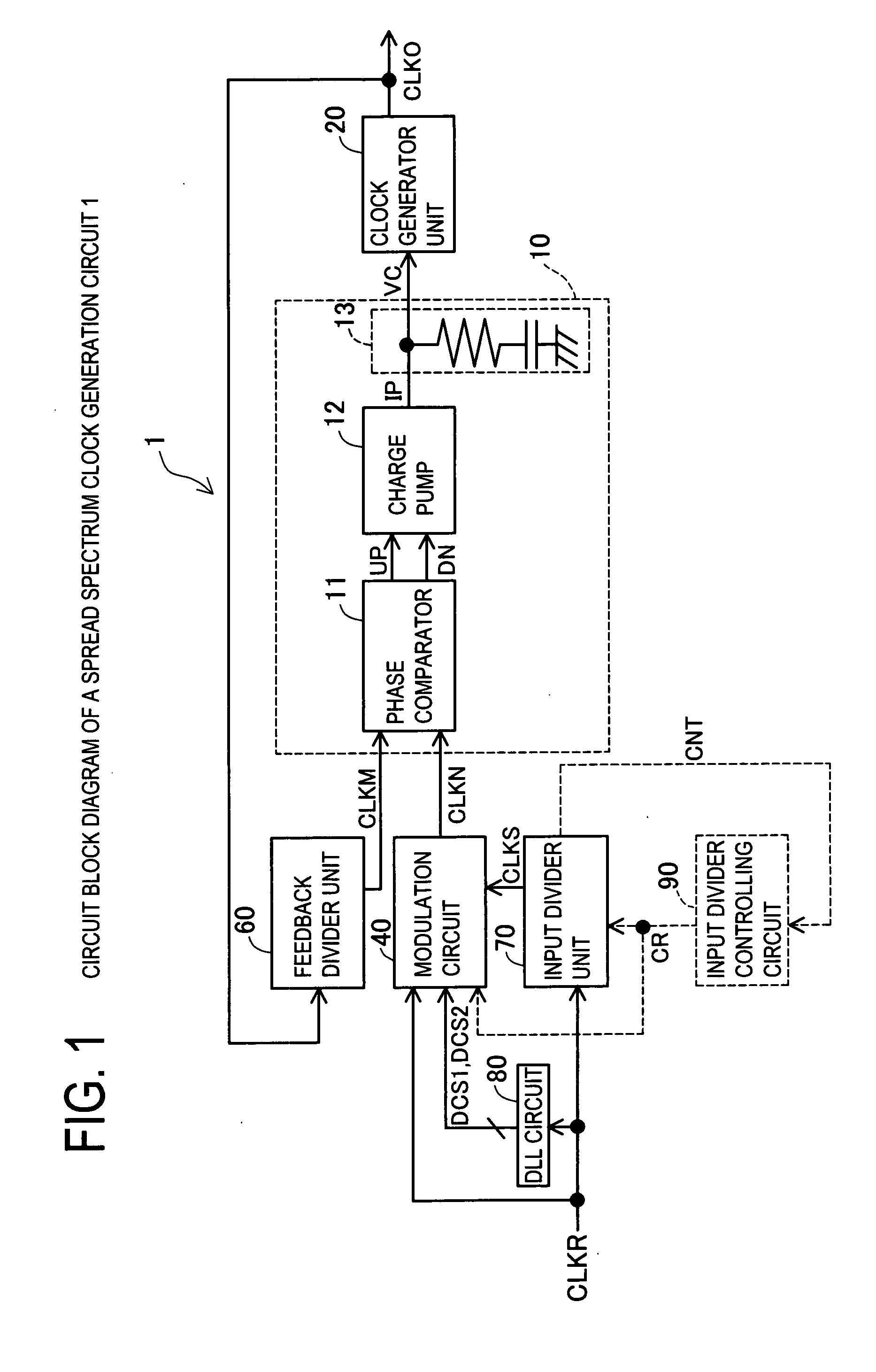

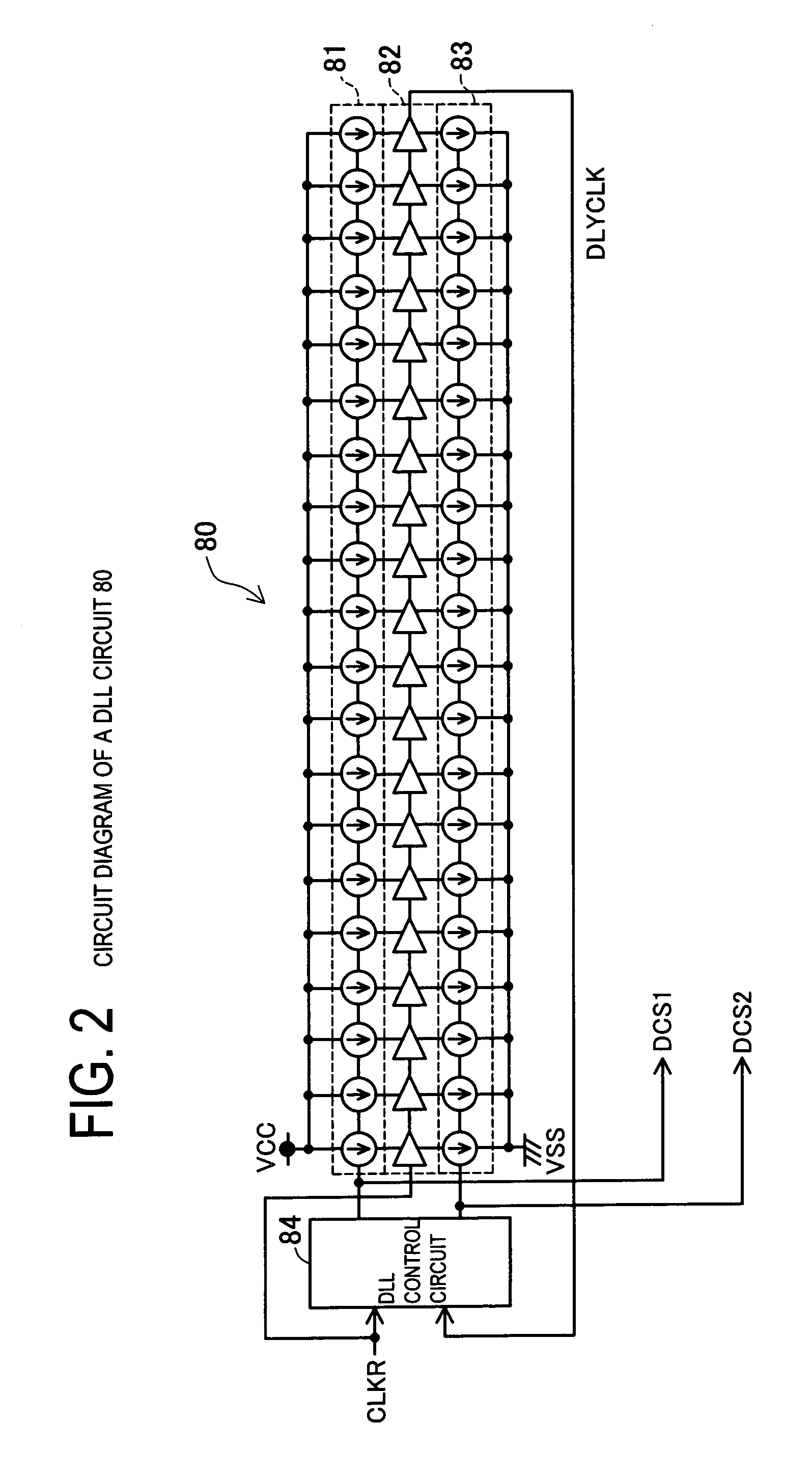

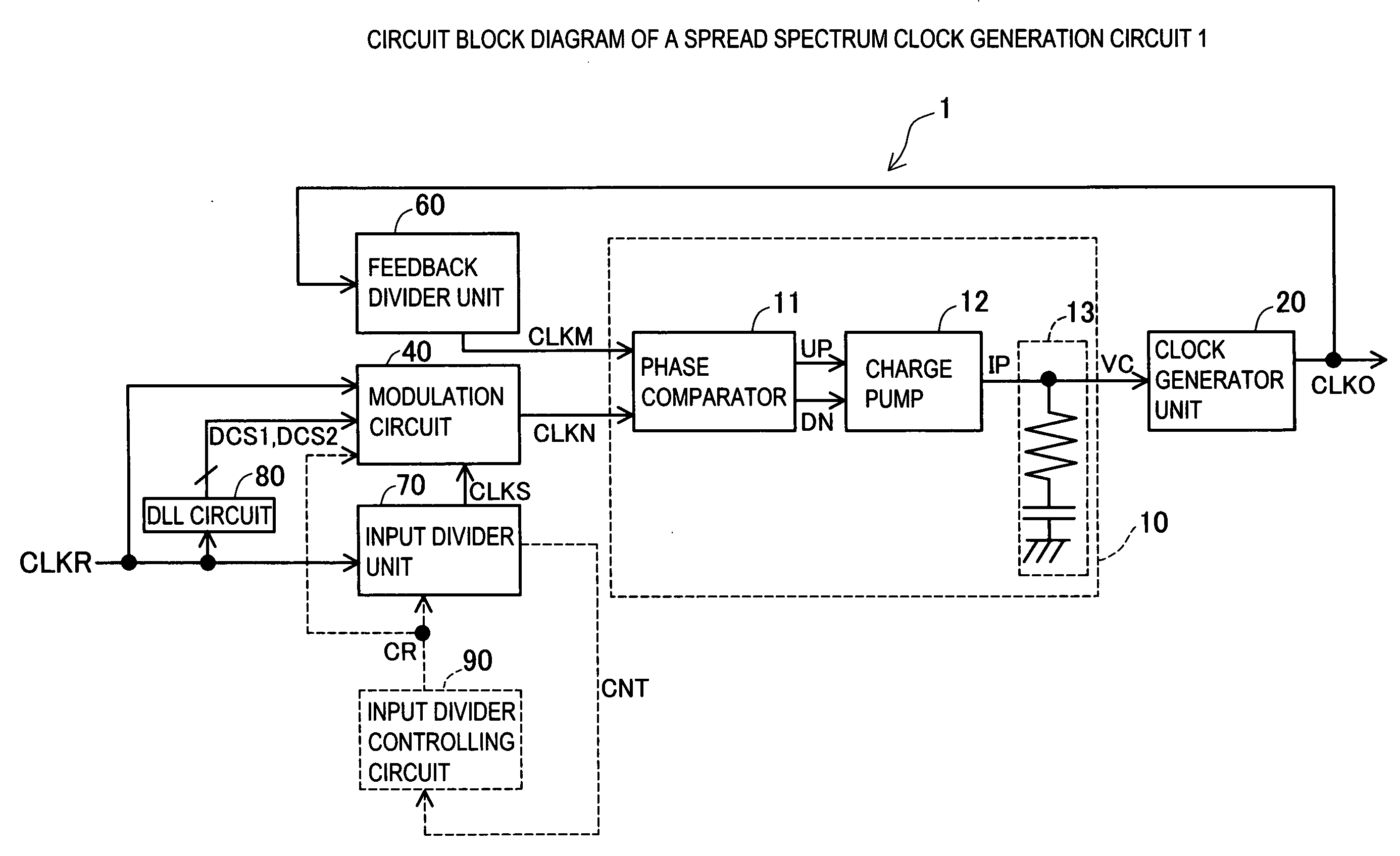

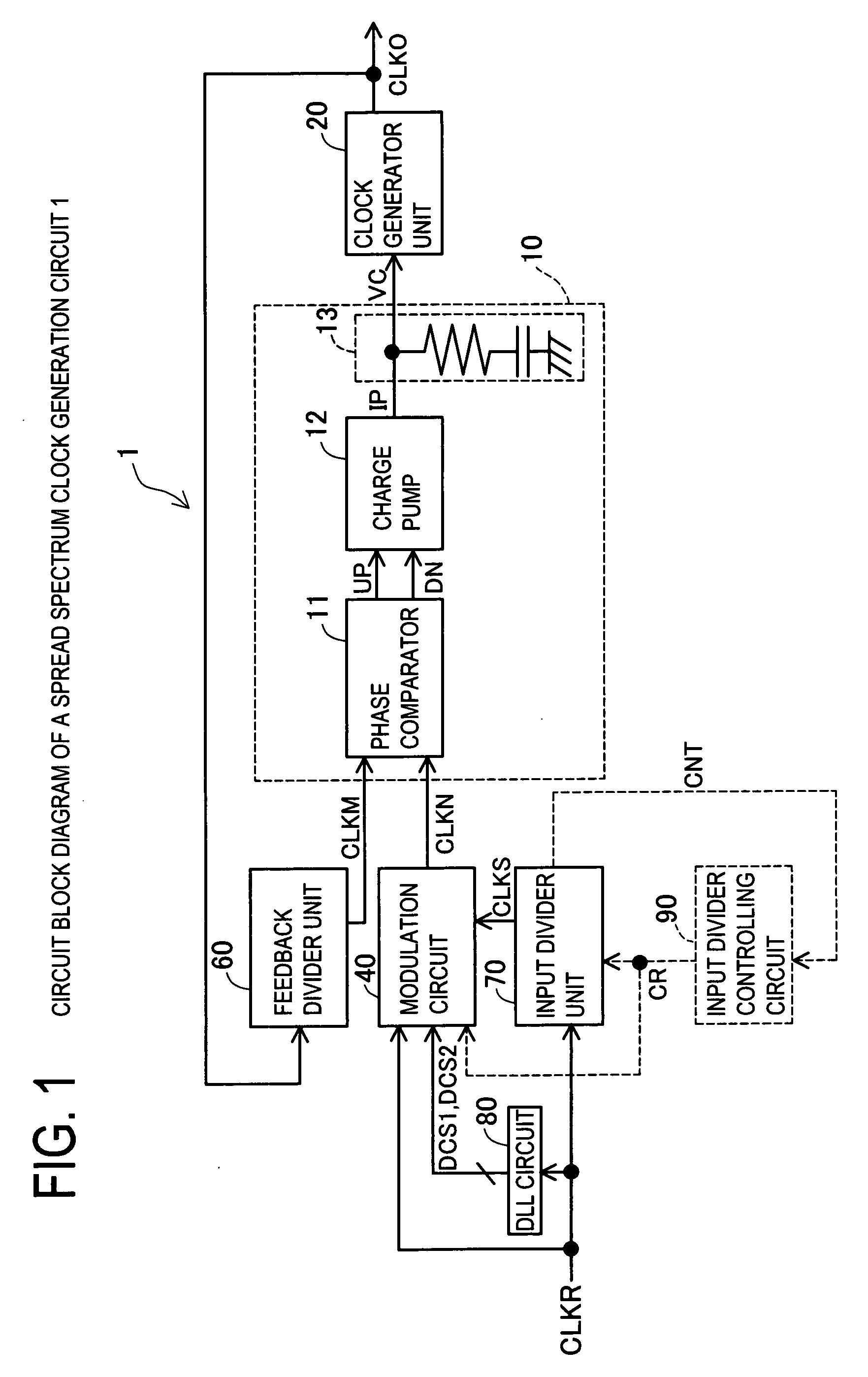

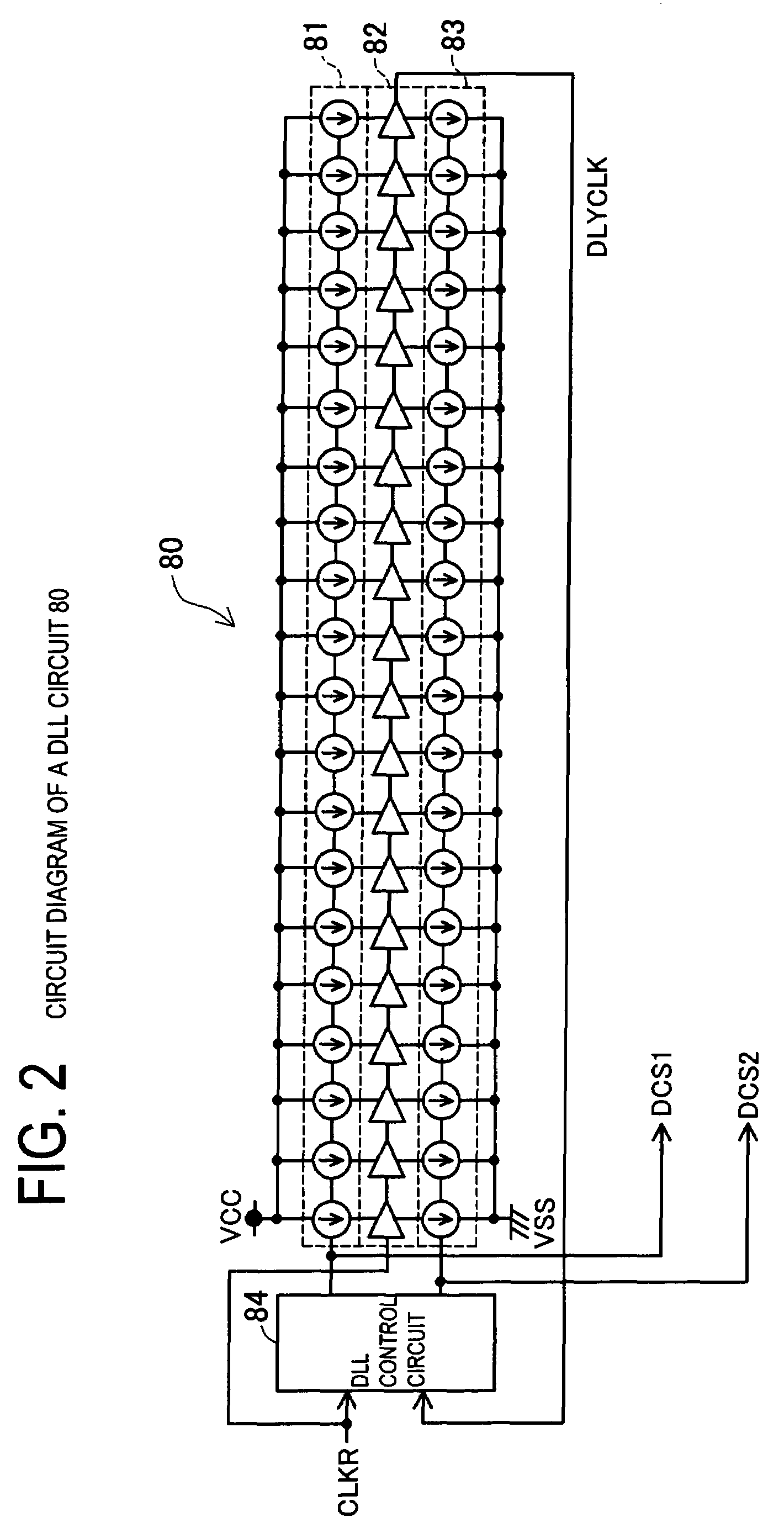

Clock generation circuit and clock generation method

ActiveUS20070057709A1High accuracyPrecise phase controlPulse automatic controlSingle output arrangementsEngineeringPhase control

A clock generation circuit and a clock generation method are provided, which are capable of spread spectrum clock generation and accurate phase control of a reference clock signal and an output clock signal. To this end, an input divider unit 70 divides an input clock signal CLKR by 50 to output a divided input clock signal CLKS. A DLL circuit 80 operates to obtain delay control signals DCS1, DCS2. A modulation circuit 40 modulates, in response to the delay control signals DCS1, DCS2 and a modulation signal MOD output from a modulation control circuit 50, the divided input clock signal CLKS to output a modulation clock signal CLKN. A phase comparator 11 detects the phase difference between the modulation clock signal CLKN and a divided inner clock signal CLKM. A clock generation unit 20 generates an output clock signal CLKO having frequency corresponding to a phase difference signal from the phase comparator 11.

Owner:MONTEREY RES LLC

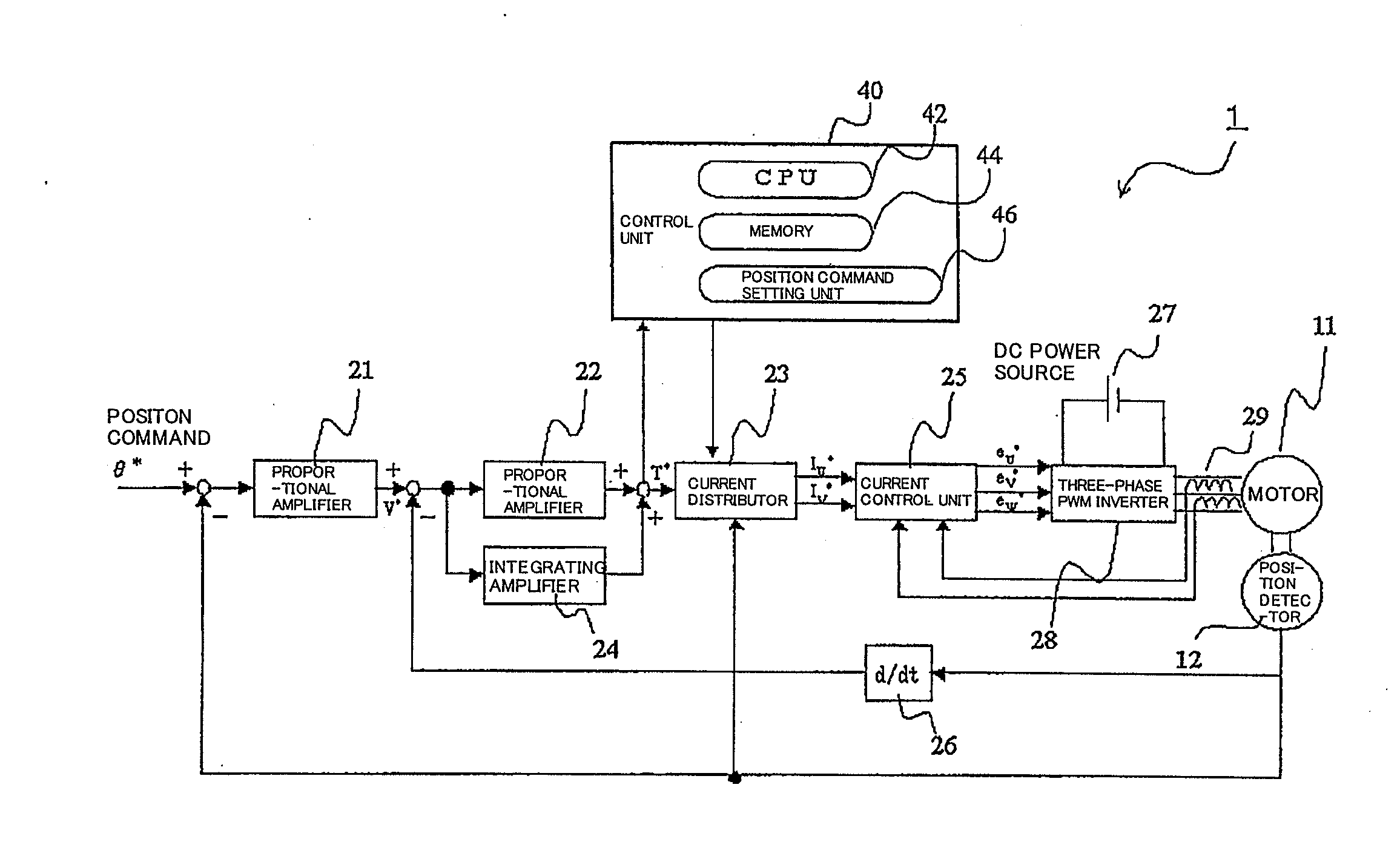

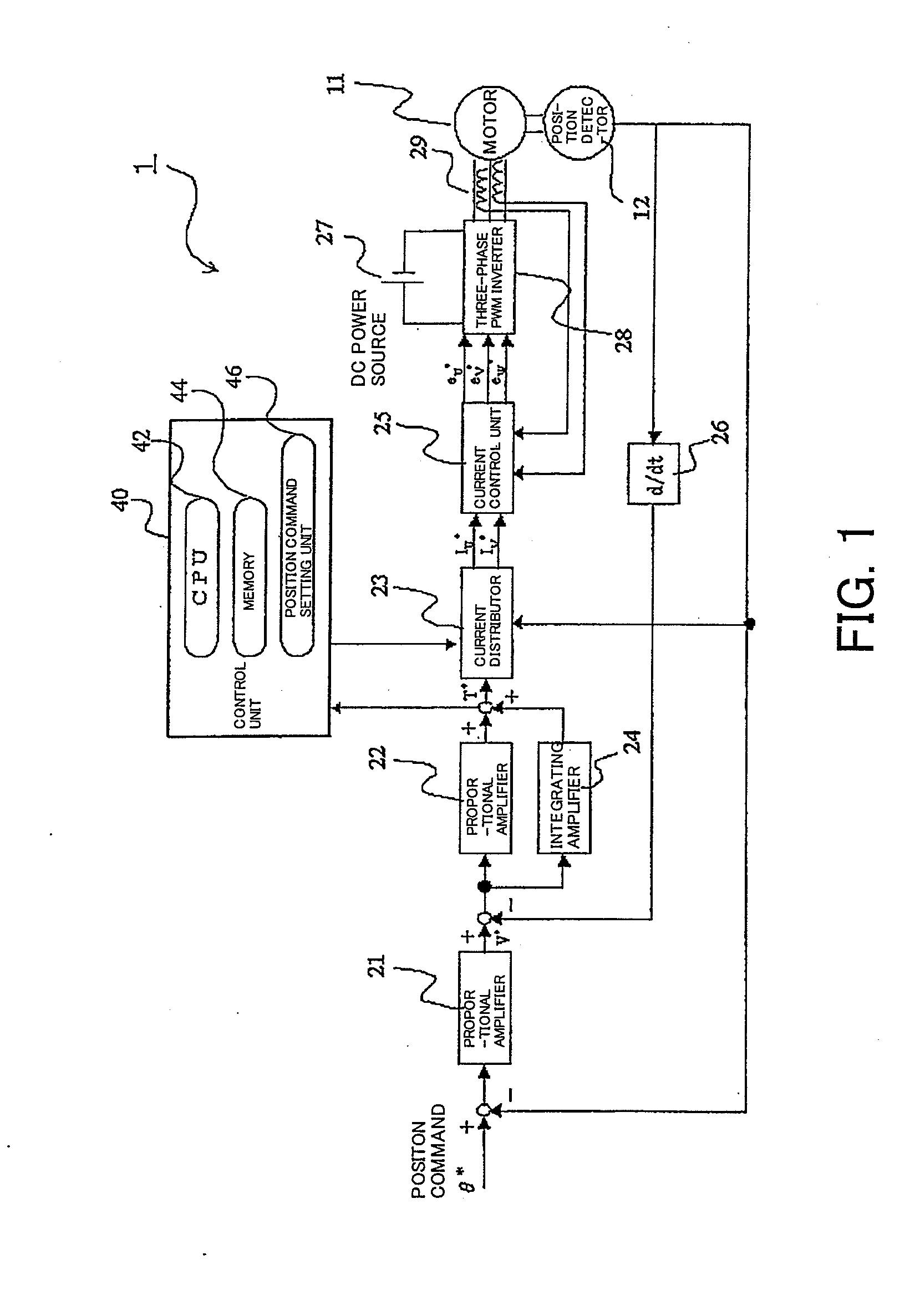

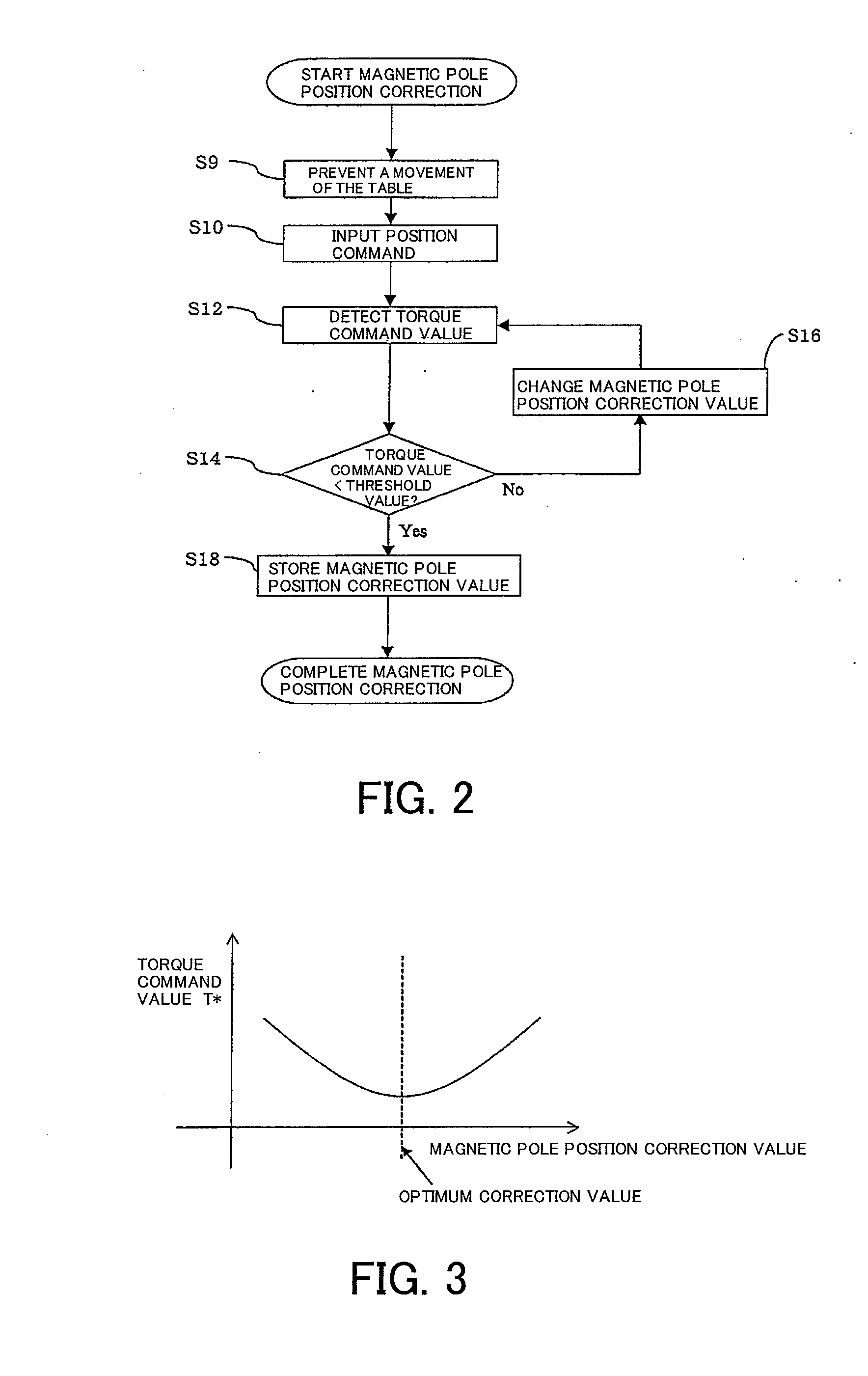

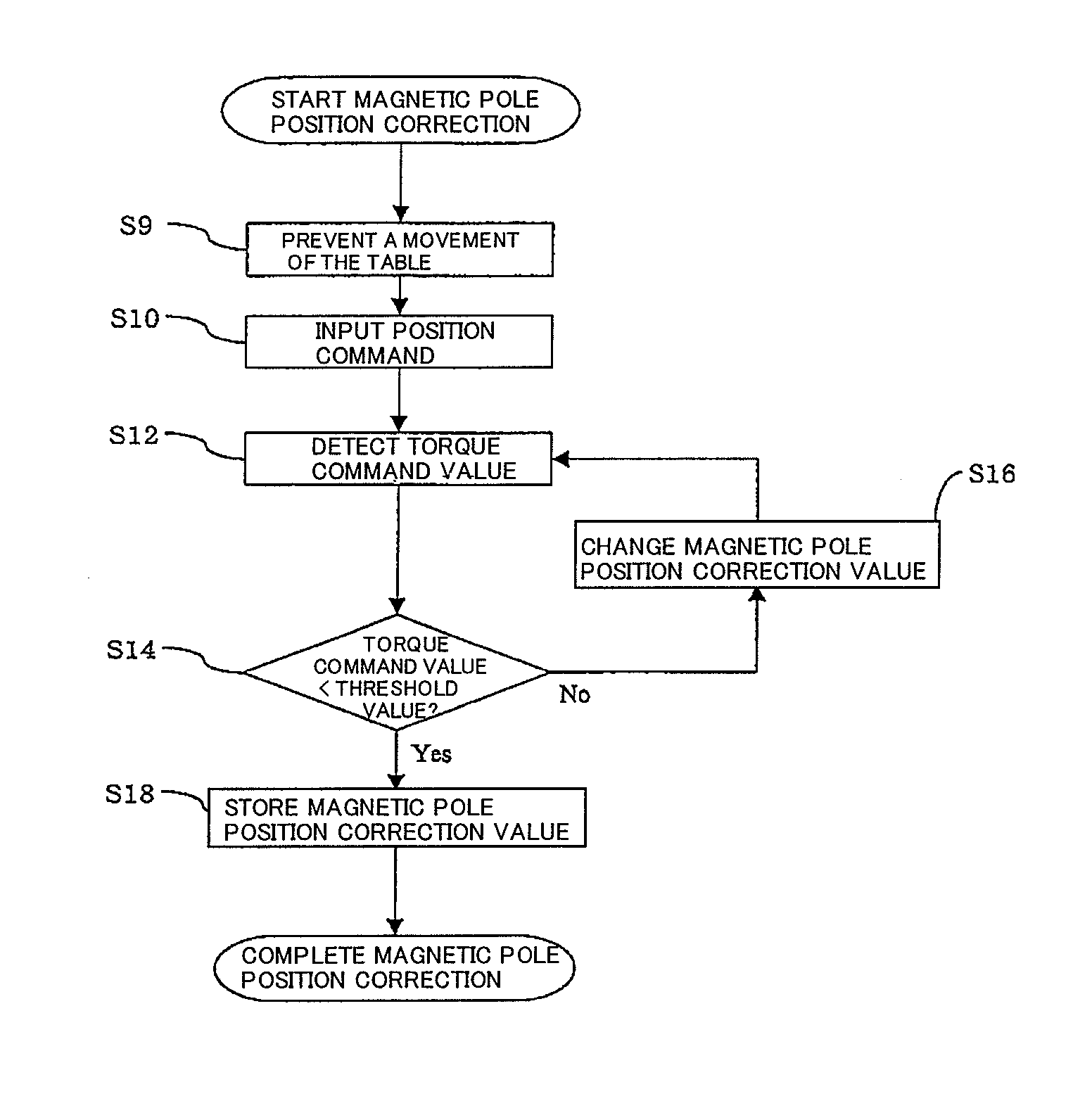

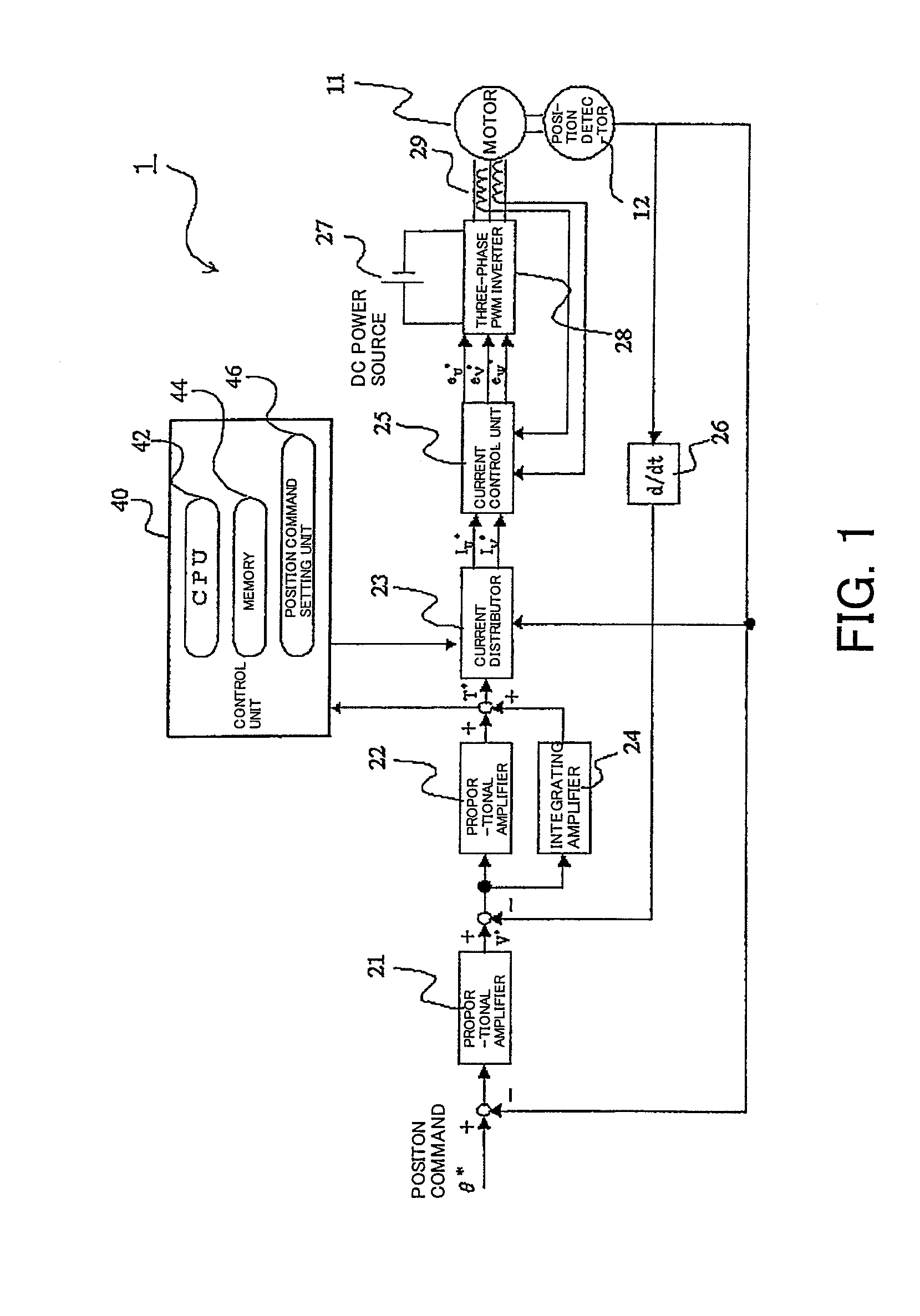

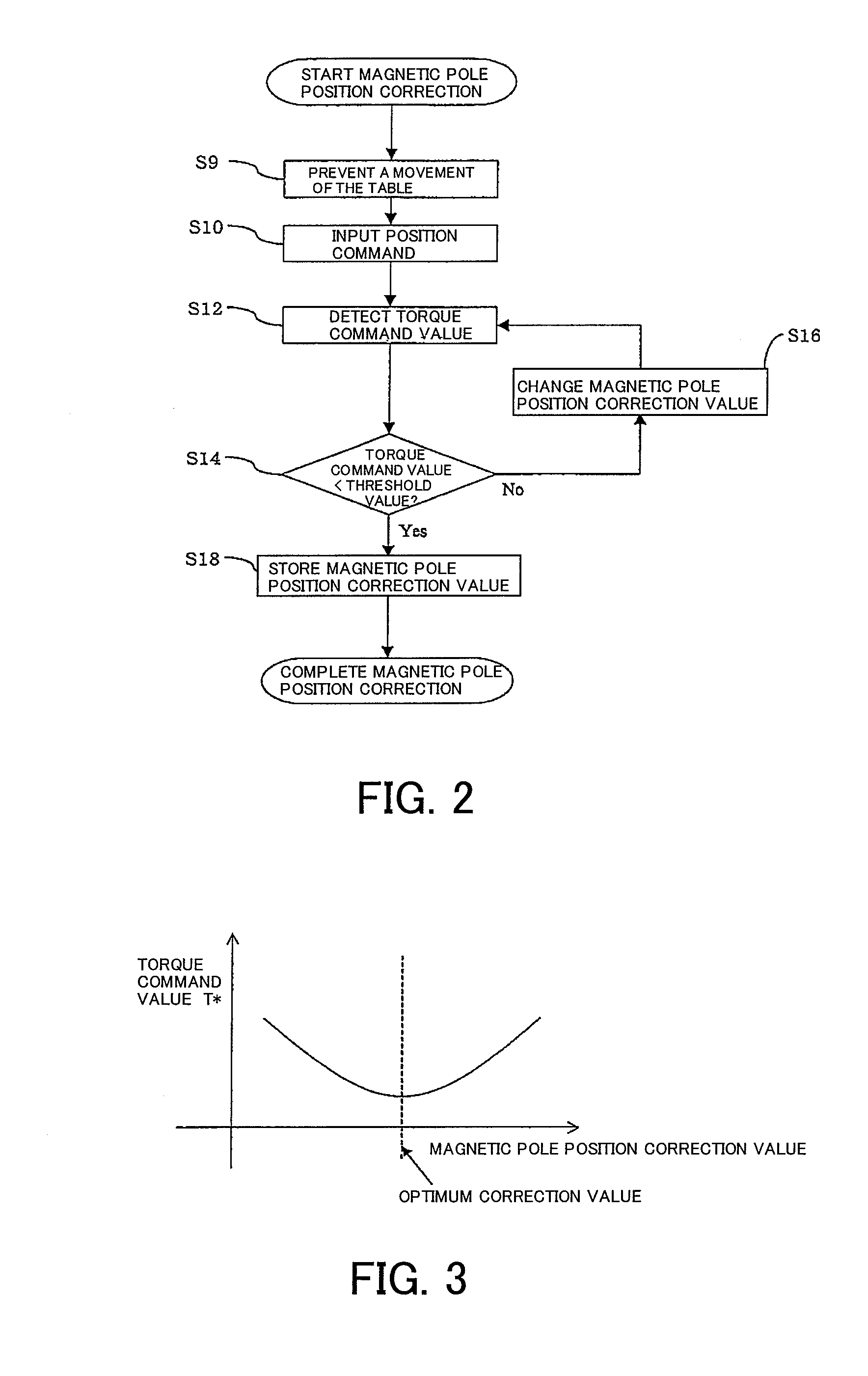

Motor magnetic pole position correction method

ActiveUS20120133311A1Eliminate any undesirable reduction in output torquePrecise phase controlSynchronous motors startersVector control systemsMagnetic polesMotor control

A motor magnetic pole position correction method includes preventing a movement of a movable element of a direct drive motor by mechanical brake (step S9), generating a command that designates a position spaced or separated from the present position (step S10), detecting a torque command value of the direct drive motor (step S12), determining a magnetic pole position correction value based on a comparison between the detected torque command value and a predetermined threshold value (steps S14 and S16), storing the determined magnetic pole position correction value in a memory (step S18), and performing motor control using an electrical angle offset value obtained based on the magnetic pole position correction value stored in the memory.

Owner:OKUMA CORP

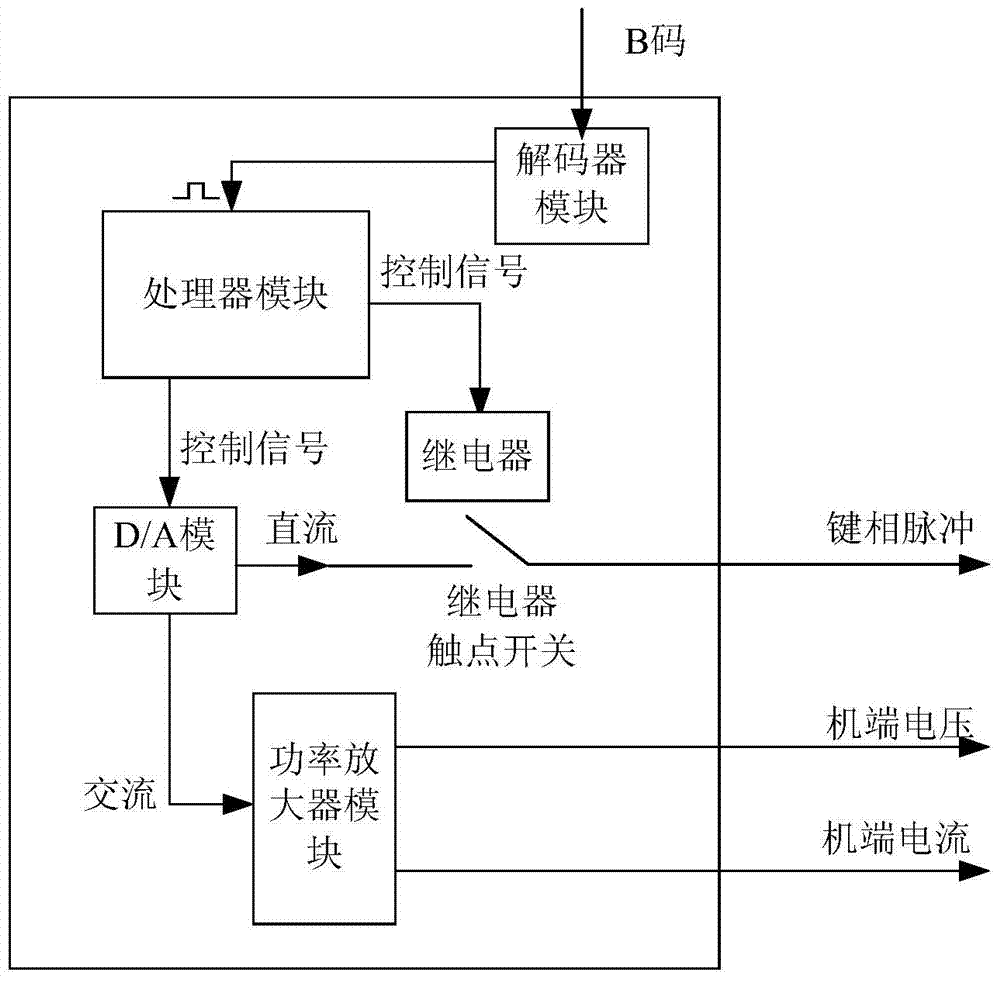

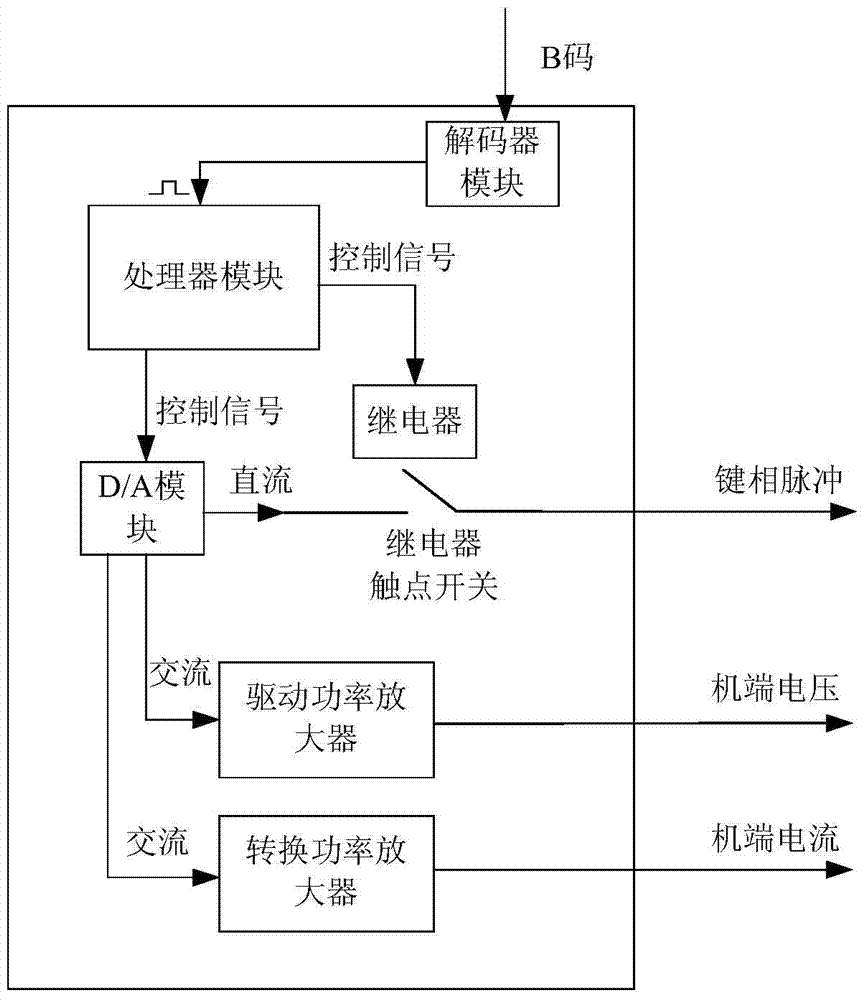

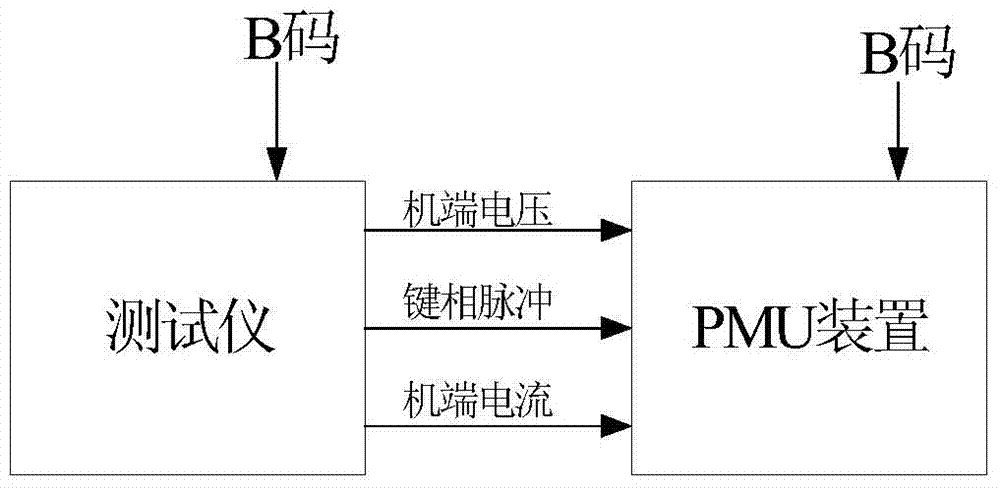

Tester for testing measurement accuracy of PMU (Pressure Measuring Unit) and testing method thereof

ActiveCN103698728APrecise control of high level valuePrecisely control the output cycleElectrical measurementsAudio power amplifierControl signal

The invention provides a tester for testing measurement accuracy of a PMU (Pressure Measuring Unit). The tester comprises a processor module, a D / A (Digital / Analog) conversion module, an electronic switch module, a power amplifier module and a decoder module. A B code time tick outputs a clock synchronization signal to the processor module through the decoder module; the processor module outputs a D / A control signal to control the D / A conversion module to output a direct voltage signal and an alternating voltage signal; the processor module outputs a switch control signal to control the electronic switch module to be switched on or off; the direct voltage signal outputs an analog key phase pulse signal through the electronic switch module; the power amplifier module comprises a driving power amplifier and a switching power amplifier; the alternating voltage signal is amplified through the driving power amplifier to output an analog machine end voltage signal; the analog machine end voltage signal is converted into an alternating current signal through the switching power amplifier; an analog machine end current signal is output. The invention also provides a method applying the tester to test the measurement accuracy of the PMU.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

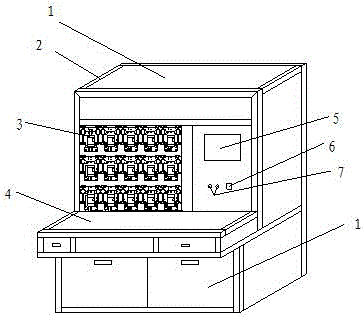

Cost control circuit breaker function test intelligent test device

PendingCN106405403APrecise frequency controlPrecise control rangeCircuit interrupters testingCost ControlsEngineering

The invention discloses a cost control circuit breaker function test intelligent test device, which belongs to the technical field of circuit breaker testing. The device provided by the invention solves the problems of scattered test function, low integration degree and uncoordinated inside test system of the existing standard characteristic test table. The test efficiency and precision are improved, which simplifies operation. The test device provided by the invention comprises a cabinet body, a control part and a wiring part. The wiring part comprises a station tooling fixture and a standard test wire. The control part comprises a test unit, a test sensor, an industrial control computer, a touch screen, a start and stop button and a variable frequency current source. The test unit comprises a first alternating current contactor, a voltage regulator, a second alternating current contactor, a collecting current plate, a signal collecting plate, a voltage regulator and a switching power supply. The test device provided by the invention is applicable to the function test of a cost control circuit breaker, and has the characteristics of rich test function, fast speed, high human-computer interaction, broad market prospect and the like.

Owner:CHINA ELECTRIC POWER RES INST +1

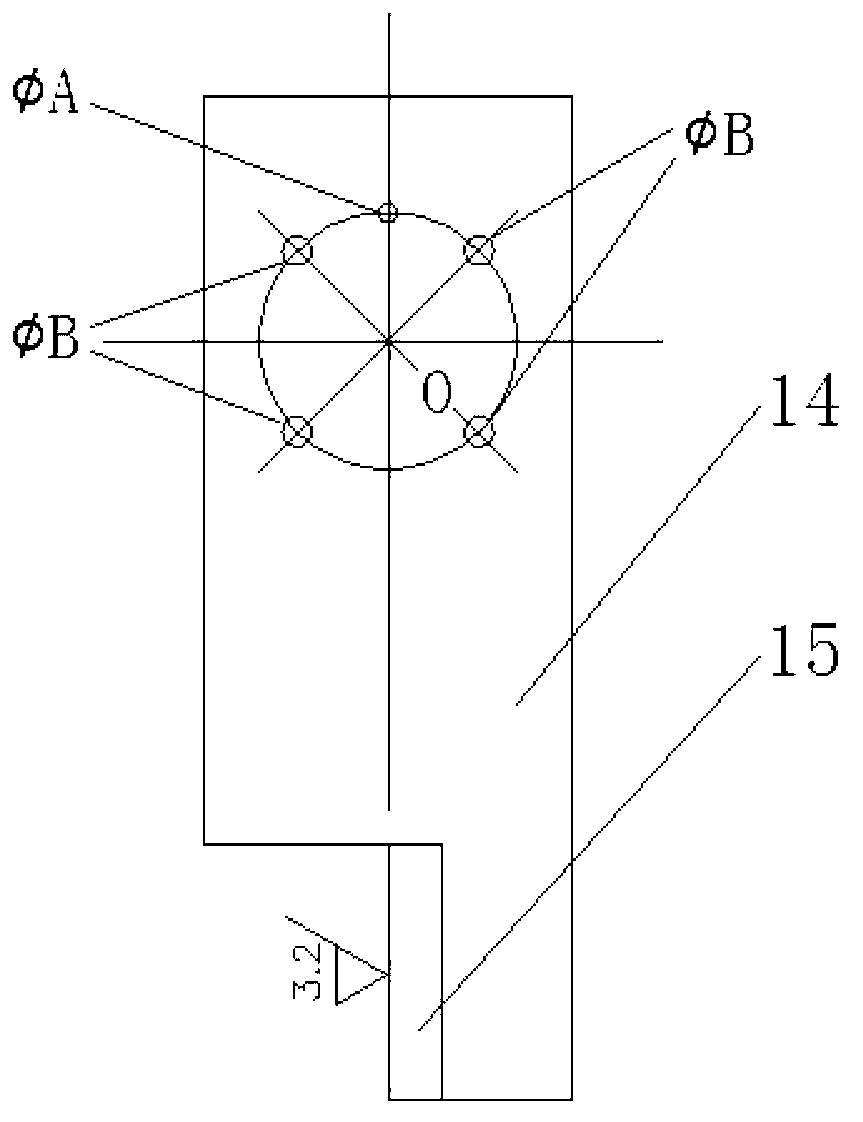

Assembly phase control method of crank head connecting block for large-interference crank shear

ActiveCN103008969AAvoid problems that cannot be overlapped and cannot be usedEasy to operateMetal working apparatusEngineeringPhase control

The invention discloses an assembly phase control method of a crank head connecting block for a large-interference crank shear. The assembly phase control method comprises the following steps of: 1. production of tooling; 2. on a connecting plate, according to the indexing size of the same position of four screw holes used for buckling with a gland on the outer end surface of an upper crank head connecting block, respectively marking out processing lines of four holes B corresponding to the four screw holes one by one; 3. connecting the tooling and the upper crank head connecting block by four screws into an assembly body in a buckling way; 4. processing holes A in the tooling and the upper crank head connecting block, and then putting dowels in the holes A; and an angle milling head milling the processing surface of a transverse plate on the tooling; 5. assembling a lower crank head connecting block, and then assembling the upper crank head connecting block, so that the Ra3.2mum processing surface of the transverse plate on the tooling can cling to a lower shear blade surface to slide; and 6. dismantling the tooling, and assembling other parts. According to the method provided by the invention, the phase can be precisely controlled, and the installation is successful once.

Owner:MCC SFRE HEAVY IND EQUIP

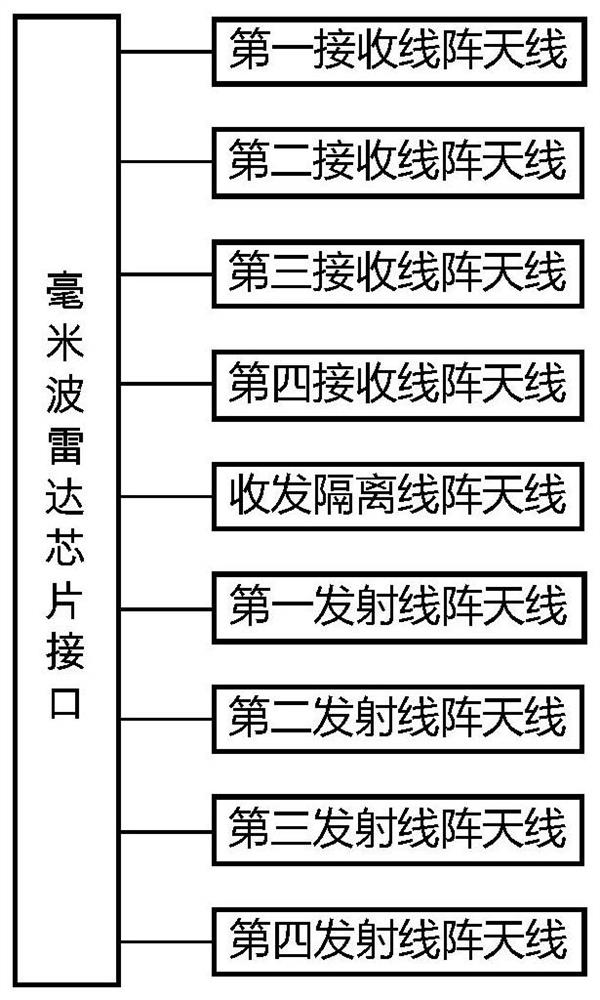

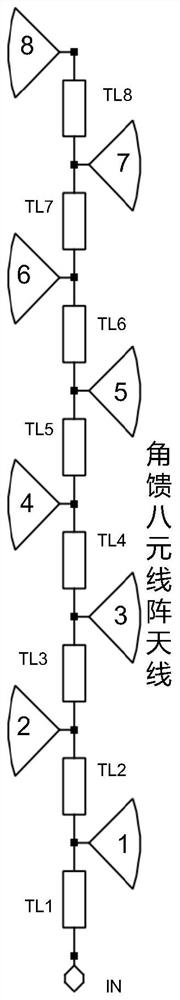

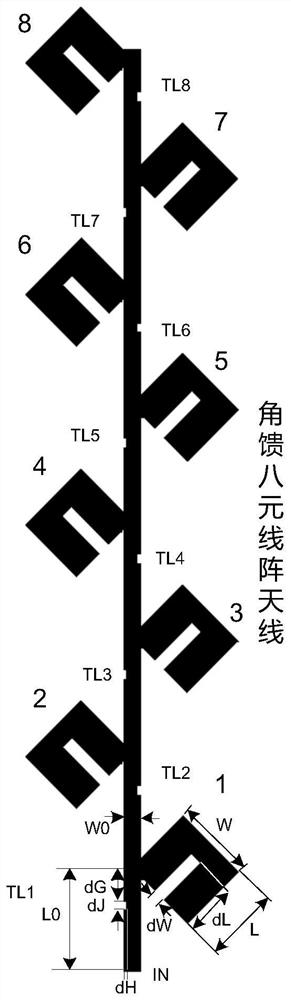

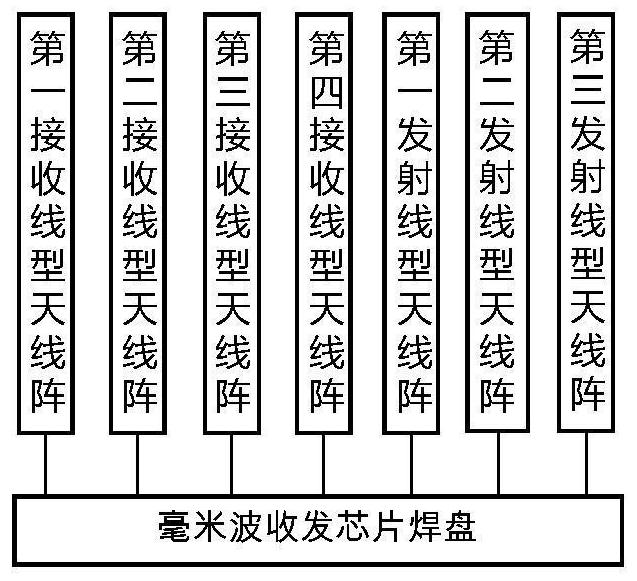

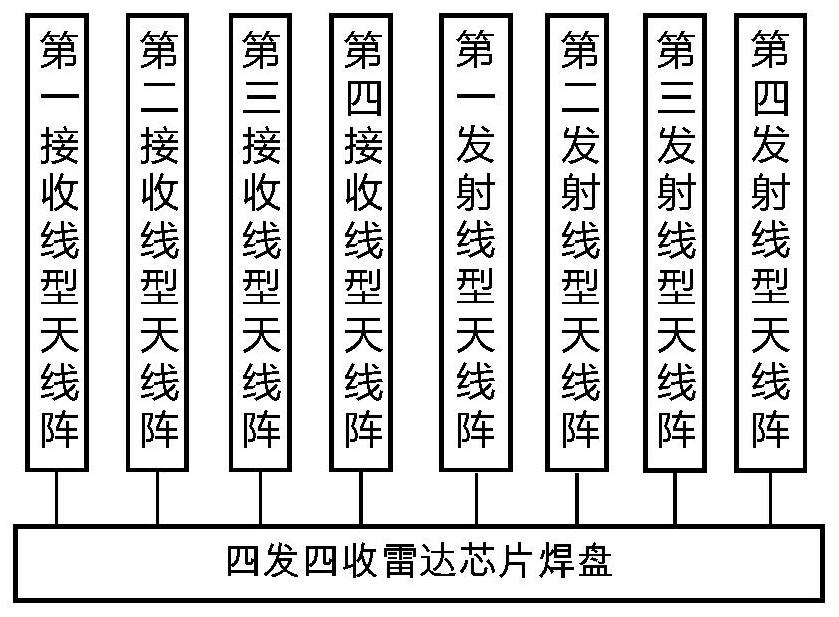

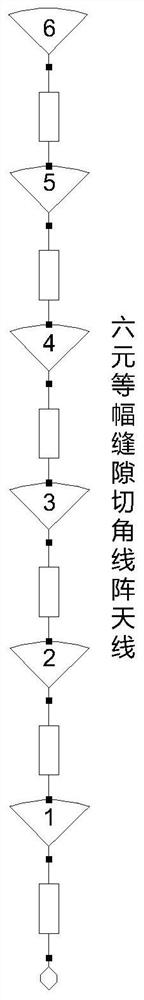

High-gain automobile millimeter-wave radar array antenna

PendingCN112103645AImprove stabilityHigh precisionAntenna adaptation in movable bodiesIndividually energised antenna arraysSoftware engineeringDistance detection

The invention discloses a high-gain automobile millimeter wave radar array antenna. The high-gain automobile millimeter wave radar array antenna comprises a millimeter wave radar chip interface, a first receiving linear array antenna, a second receiving linear array antenna, a third receiving linear array antenna, a fourth receiving linear array antenna, a transceiving isolation linear array antenna, a first transmitting linear array antenna, a second transmitting linear array antenna, a third transmitting linear array antenna and a fourth transmitting linear array antenna. The core architecture of the high-gain automobile millimeter wave radar array antenna adopts a four-transmitting and four-receiving antenna array mode, adopts eight angle-feed array elements with same phase and same amplitude as a transmitting unit, and combines a combination method of tangential circular polarization and surface slotting of a symmetrical structure to reasonably suppress the sidelobe level of the antenna, control the size and the position of an antenna parasitic unit, optimize the radiation characteristic of the antenna and improve the impedance matching characteristic. The high-gain automobilemillimeter wave radar array antenna has the advantages of high precision, high response speed, high resolution, high stability, miniaturization and low cost, and can be used for medium-distance and long-distance detection millimeter wave radar system schemes.

Owner:成都多普勒科技有限公司 +1

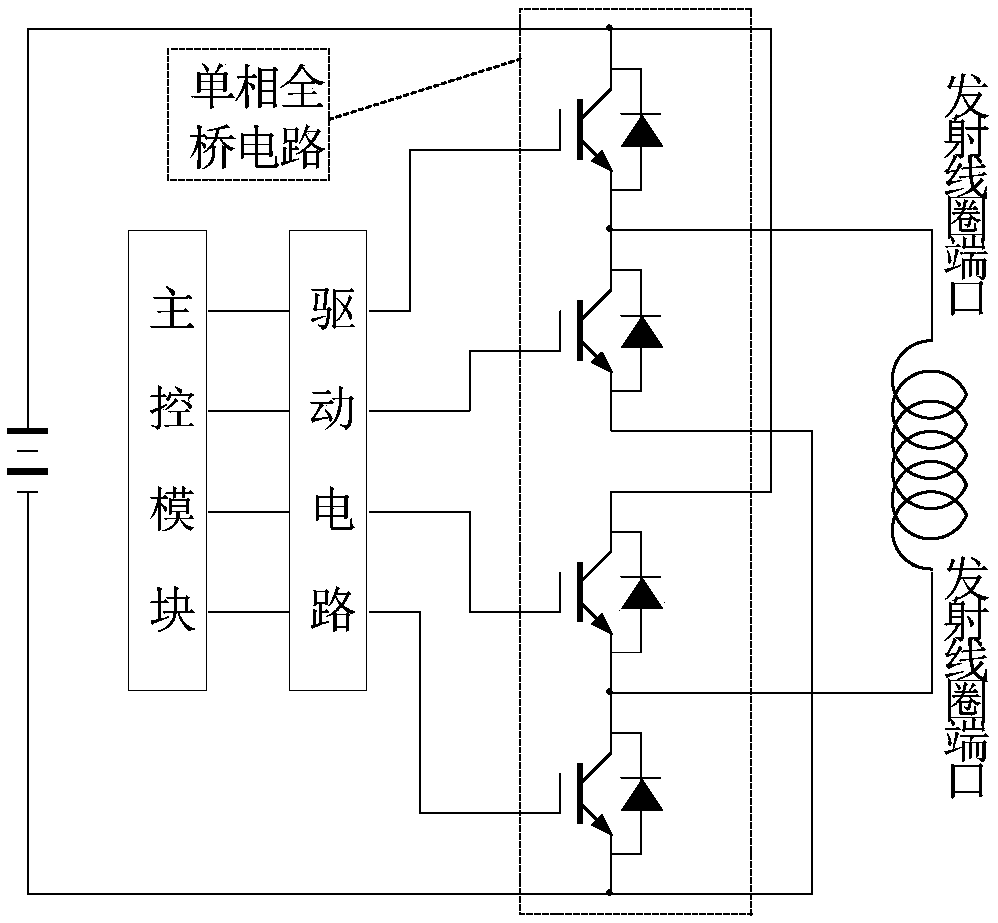

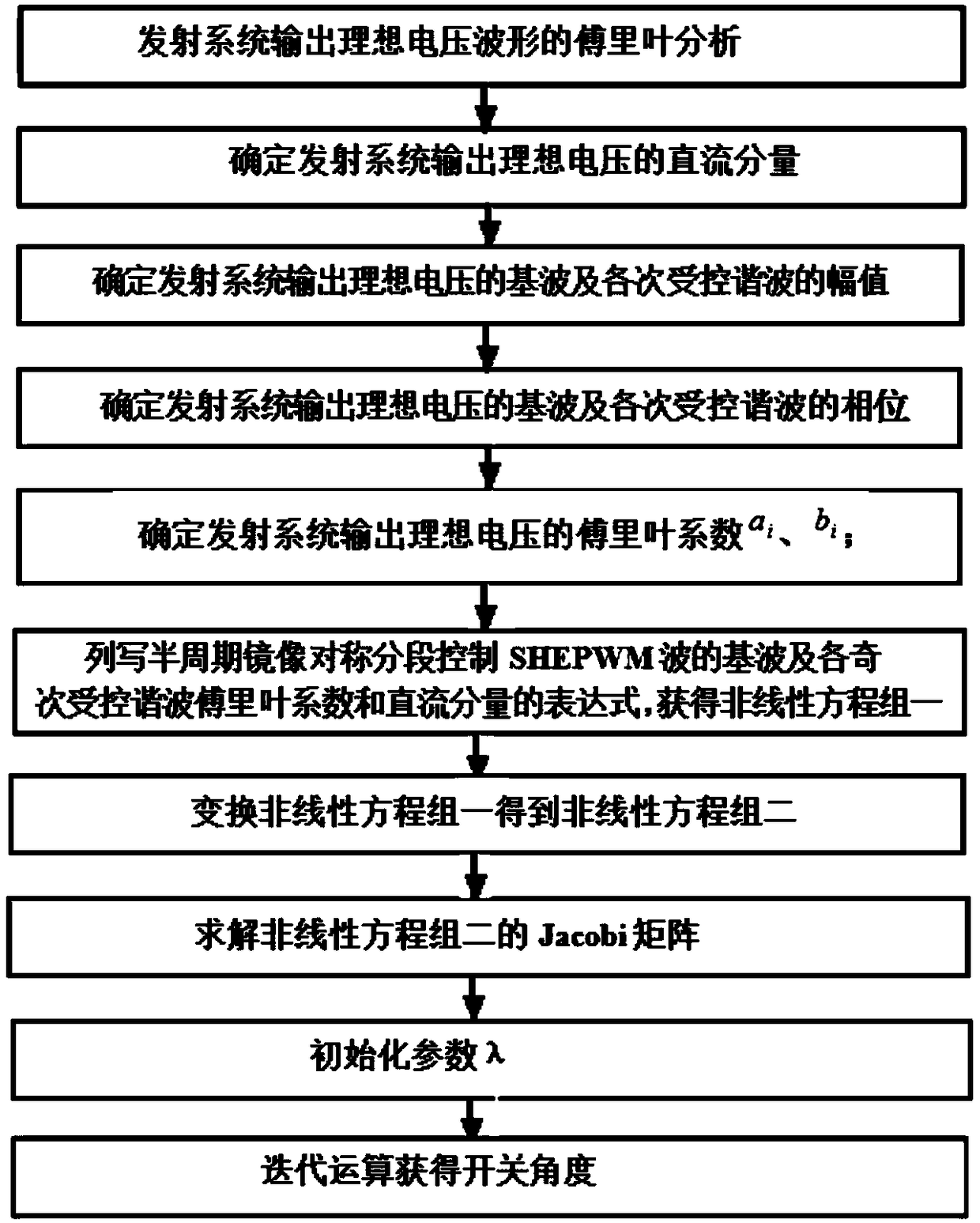

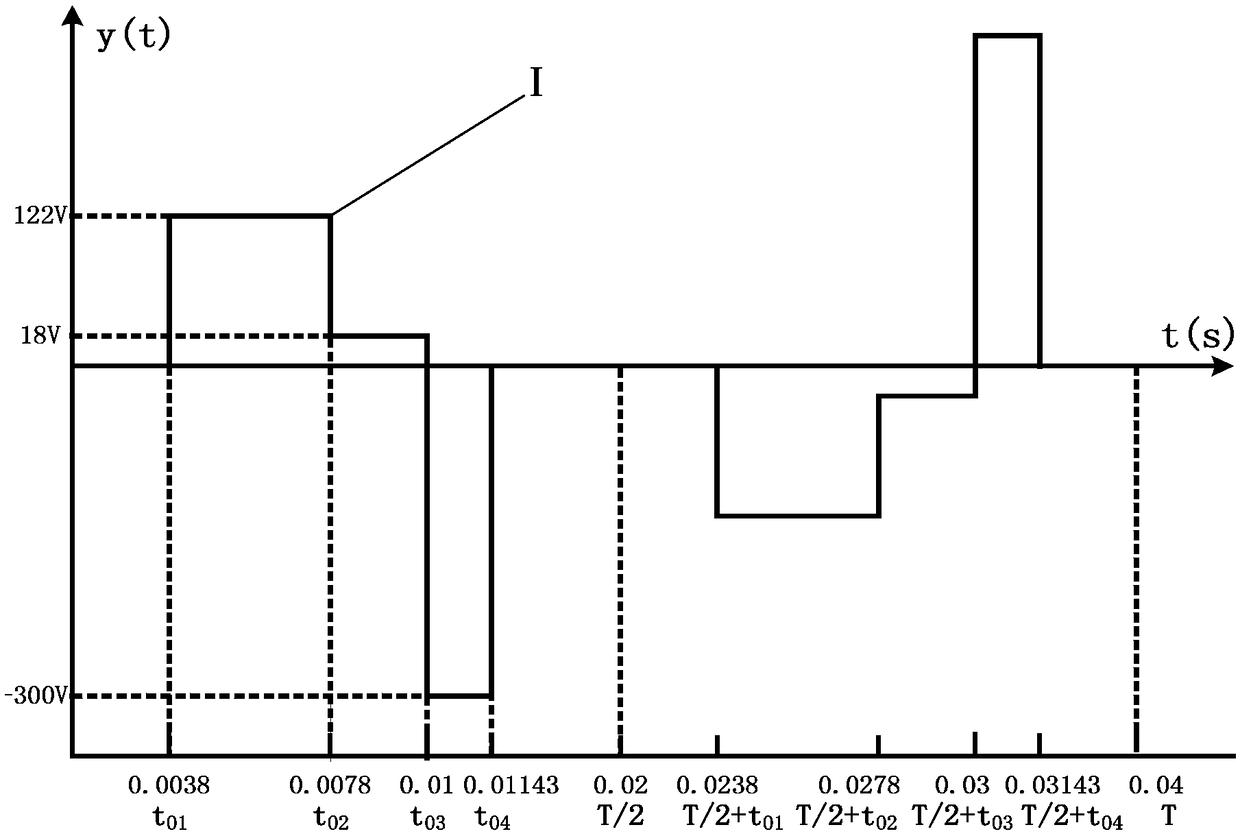

Helicopter airborne time-domain SHEPWM detection signal segmented control method

InactiveCN109143380ADC component precise controlPrecisely control the fundamental waveElectric/magnetic detectionAcoustic wave reradiationPower inverterHarmonic

The invention relates to a helicopter airborne time-domain SHEPWM (Selective Harmonic Elimination Pulse Width Modulation) detection signal segmented control method. Through Fourier transformation of the ideal output voltage of a helicopter airborne time-domain electromagnetic emission system, an SHEPWM segmented control nonlinear equation set under the condition of semi-cycle mirror symmetry of the ideal output voltage waveform of the emission system is put forward. A switching time sequence corresponding to the ideal output voltage is obtained through a neural network recursive algorithm to realize accurate control of the DC component as well as the amplitudes and phases of the fundamental wave and odd controlled harmonics of the ideal output voltage waveform of the inverter of the emission system. Thus, the switching frequency is reduced, the time-domain and frequency-domain quality of the emission current is improved, and the efficiency of the system is improved. The method of the invention is applied to a helicopter airborne time-domain electromagnetic emission system, and can improve the efficiency of the system while ensuring the detection accuracy.

Owner:JILIN UNIV

PCI integrated circuit board device used for ARINC429 communication

InactiveCN101571842BSimple structureIncrease flexibilityElectric digital data processingProtocol processingPci interface

The invention discloses a PCI integrated circuit board device used for ARINC429, mainly comprising an FPGA module, an ARINC429 interface chip, two ARINC429 protocol processing chips, two ARINC429 signal output linear drive chips and a power switching circuit. The FPGA chip is used for realizing PCI interface protocol and completing information interaction and control of a host computer and the board; the FPGA chip executes instruction of the host computer, initializes the ARINC429 interface chip and realizes control and caching of sending and receiving data to realize independent four receiving and two sending function and data sending rate adjustable function. The invention is flexible in configuration, the sending rate is adjustable and is wide in adjustable range, circuit construction is simple, processing cost of the circuit board is low, and different requirements of ARINC429 communication can be completed only by modifying FPGA software without changing hardware, thus the invention has strong commonality and flexibility.

Owner:BEIHANG UNIV

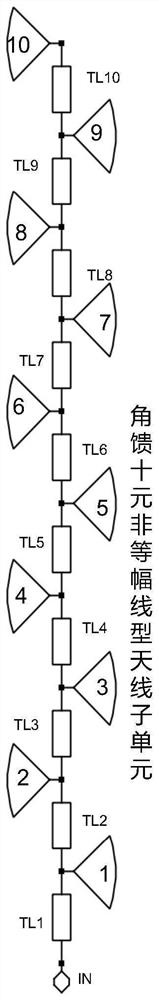

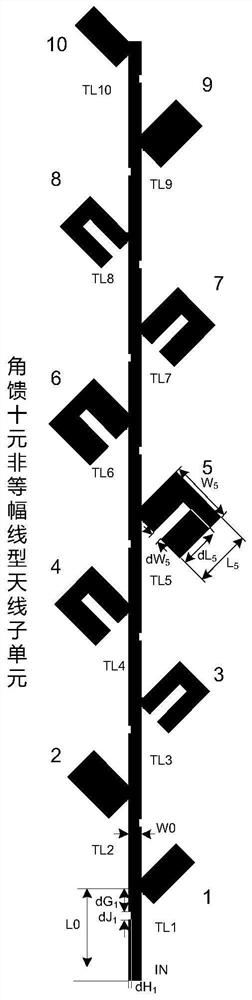

An array antenna for automotive radar sensor

PendingCN112103667AImprove stabilityHigh precisionAntenna adaptation in movable bodiesIndividually energised antenna arraysImpedance matchingMillimetre wave

The invention discloses an array antenna for an automobile radar sensor, and the array antenna comprises a millimeter wave receiving and transmitting chip bonding pad, a first receiving linear antennaarray, a second receiving linear antenna array, a third receiving linear antenna array, a fourth receiving linear antenna array, a first transmitting linear antenna array, a second transmitting linear antenna array, and a third transmitting linear antenna array. The core architecture of the array antenna adopts a three-transmitting four-receiving antenna array mode, and adopts ten in-phase non-equal amplitude angle feed array elements as a basic unit structure to control the size and position of an antenna parasitic unit, reasonably suppress the sidelobe level of the antenna and optimize theradiation characteristics of the antenna. The impedance matching characteristic is improved by combining a combination method of tangential circular polarization and surface slotting of a symmetricalstructure . According to the scheme, high precision, high response speed and high resolution can be achieved, and a millimeter wave radar system scheme for medium-distance and long-distance detectioncan be achieved.

Owner:成都多普勒科技有限公司 +1

Double-head phase friction welding machine with single-spindle box once loaded

ActiveCN103521914BLess investmentAvoid precision lossWelding/cutting auxillary devicesAuxillary welding devicesFriction weldingAngular velocity

The invention provides a single-main-shaft box one-time clamping double-end phase friction welder and belongs to the technical field of friction welders. A main shaft box is arranged on the upper portion of one side of a lathe bed. A tool locating clamping device is arranged on the upper portion of the other side of the lathe bed. A back pushing device is arranged on the upper portion of the tool locating clamping device. A main shaft is arranged in the main shaft box. A coding machine is arranged at the outer end of the main shaft. A direct-current motor component is arranged on the upper portion of the main shaft box. The direct-current motor component and the main shaft are in transmission connection through a synchronous pulley transmission mechanism. A rotating clamp is arranged at the inner end of the main shaft. During using, three workpieces are clamped at one time, accuracy loss caused by clamping again in secondary welding in a 180-degree-turning mode is avoided, welding phase accuracy is improved, and meanwhile welding production efficiency is improved. A direct-current motor is used for accurately controlling the angular velocity and the angular displacement of the main shaft, and accurate phase control of welding friction is achieved. The phase control accuracy can reach + / -0.5 degree.

Owner:哈尔滨正晨焊接切割设备制造有限公司

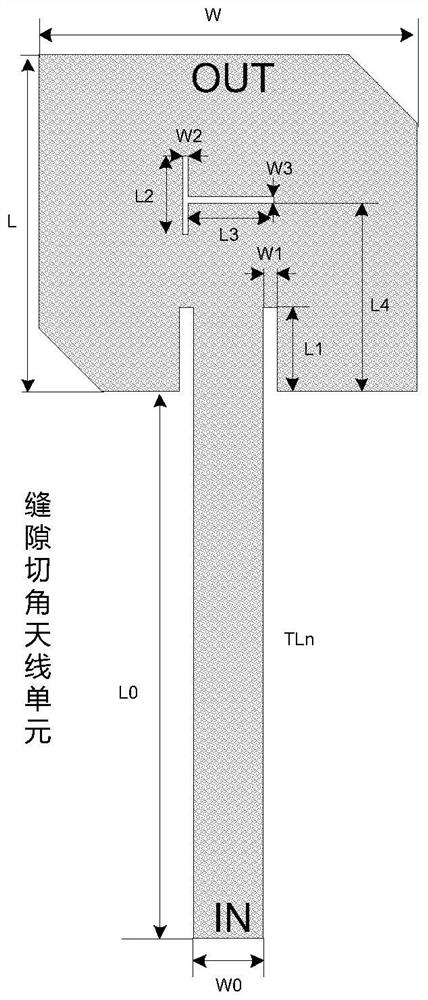

Automobile anti-collision radar array antenna

PendingCN112103666AHigh gainHigh precisionAntenna adaptation in movable bodiesIndividually energised antenna arraysTransmitted powerMillimetre wave

The invention discloses an automobile anti-collision radar array antenna. The automobile anti-collision radar array antenna comprises a four-transmitting four-receiving radar chip bonding pad, a firstreceiving linear antenna array, a second receiving linear antenna array, a third receiving linear antenna array, a fourth receiving linear antenna array, a first transmitting linear antenna array, asecond transmitting linear antenna array, a third transmitting linear antenna array, a fourth transmitting linear antenna array and a transmitting power division matching network. The core architecture of the automobile anti-collision radar array antenna adopts a four-transmitting four-receiving antenna array mode, and adopts six slot corner cut patch array elements with same phase and same amplitude as a basic unit structure to control the size and the position of an antenna parasitic unit, reasonably suppress the sidelobe level of the antenna, optimize the radiation characteristic of the antenna and improve the impedance matching characteristic.

Owner:成都多普勒科技有限公司 +1

Motor magnetic pole position correction method

ActiveUS8476851B2Eliminate any undesirable reduction in output torquePrecise phase controlSynchronous motors startersVector control systemsMagnetic polesMotor control

A motor magnetic pole position correction method includes preventing a movement of a movable element of a direct drive motor by mechanical brake (step S9), generating a command that designates a position spaced or separated from the present position (step S10), detecting a torque command value of the direct drive motor (step S12), determining a magnetic pole position correction value based on a comparison between the detected torque command value and a predetermined threshold value (steps S14 and S16), storing the determined magnetic pole position correction value in a memory (step S18), and performing motor control using an electrical angle offset value obtained based on the magnetic pole position correction value stored in the memory.

Owner:OKUMA CORP

Clock generation circuit and clock generation method

ActiveUS7276944B2Precise phase controlSpread spectrum clock generationPulse automatic controlSingle output arrangementsControl signalPhase difference

A clock generation circuit and a clock generation method are provided, which are spread spectrum clock generation and accurate phase control of a reference clock signal and an output clock signal. An input divider unit 70 divides an input clock signal CLKR by 50 to output a divided input clock signal CLKS. A DLL circuit 80 operates to obtain delay control signals DCS1, DCS2. A modulation circuit 40 modulates, in response to the delay control signals DCS1, DCS2 and a modulation signal MOD output from a modulation control circuit 50, the divided input clock signal CLKS to output a modulation clock signal CLKN. A phase comparator 11 detects the phase difference between the modulation clock signal CLKN and a divided inner clock signal CLKM. A clock generation unit 20 generates an output clock signal CLKO having frequency corresponding to a phase difference signal from the phase comparator 11.

Owner:MONTEREY RES LLC

A laser phased array multi-beam forming system and method

InactiveCN106154681BAchieve deflectionAccurate amplitudeNon-linear opticsBeam expanderBeam splitting

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

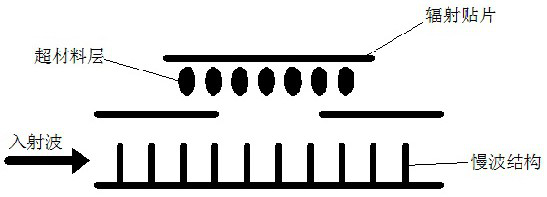

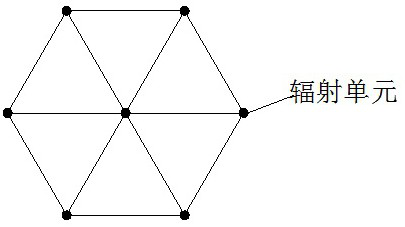

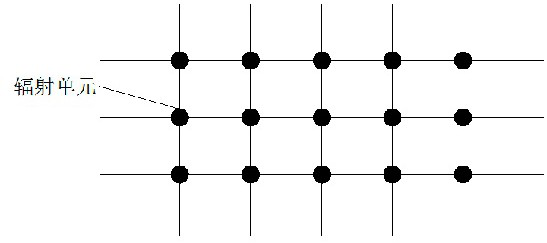

Design method of directional diagram programmable metamaterial antenna array

PendingCN112909518ALow cell coupling corresponding toArray phase control is preciseRadiating elements structural formsIndividually energised antenna arraysMetamaterial antennaWaveguide

The invention provides a design method of a directional diagram programmable metamaterial antenna array. The antenna array is composed of single radiation units, a radiation patch is located at the top of a feed waveguide slot, a metamaterial layer is arranged between the waveguide slot and the radiation patch, electromagnetic waves excite the radiation patch through the slot, and the radiation patch radiates the electromagnetic waves to the space; by accurately regulating and controlling the amplitudes and phases of the units in the array, electromagnetic waves are overlapped in space to form a required directional beam, the invention provides an arrangement mode of the directional diagram programmable metamaterial array antenna units, and the arrangement mode of the array units comprises equilateral triangle array arrangement, rectangular array arrangement and annular array arrangement; each arrangement mode can control the antenna array directional diagram through a corresponding algorithm.

Owner:北京道古视界科技有限公司

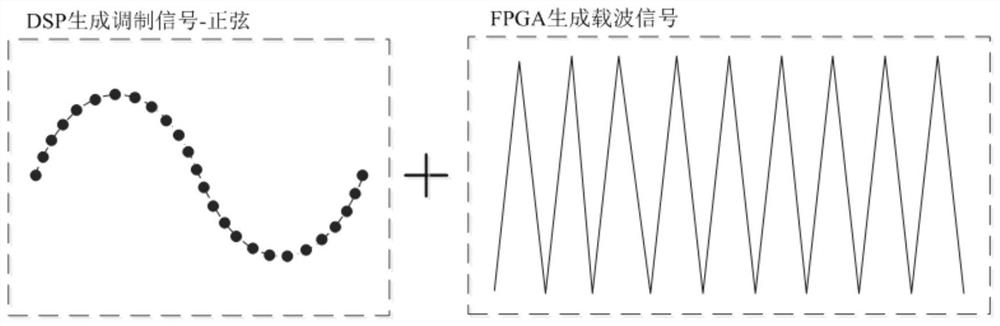

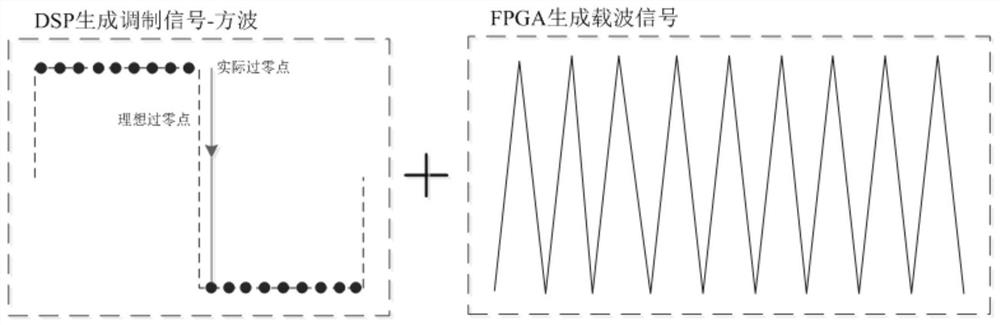

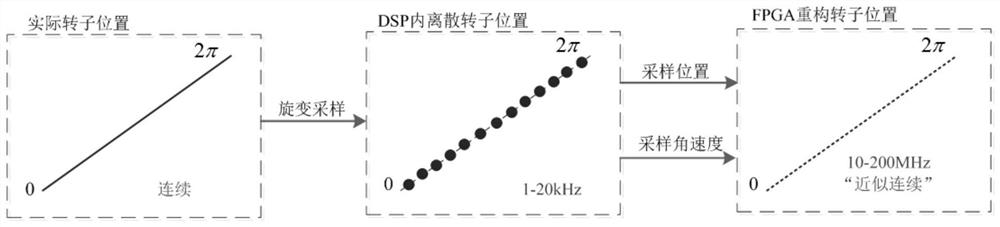

Square wave field weakening control method for permanent magnet synchronous motor

ActiveCN109245641BPrecise phase controlAvoid phase errorElectronic commutation motor controlElectric motor controlSquare waveformPermanent magnet synchronous motor

The invention provides a square wave field weakening control method for a permanent magnet synchronous motor, comprising the following steps: in each sampling cycle of a DSP chip, sending the rotor position information and rotational speed information obtained by sampling to the FPGA chip; The obtained discrete rotor position signal is reconstructed; the FPGA chip shortens the discrete period of the original discrete rotor position signal to generate a new rotor position signal; the reconstructed rotor position signal is considered to be an approximate continuous rotor position signal; each sampling period of the DSP chip Inside, the DSP chip sends the voltage phasor angle to the FPGA chip; the FPGA chip performs phase-shift processing on the reconstructed rotor position signal according to the voltage vector angle to obtain the square wave drive pulse phase angle; the FPGA chip uses the square wave drive pulse phase angle Generate three-phase drive pulses to achieve precise control of the phase of drive pulses from a square wave. The invention greatly improves the asymmetrical problem of positive and negative half cycle of the driving pulse of the square wave field weakening control by improving the generation mode of the square wave driving pulse.

Owner:NAVAL UNIV OF ENG PLA

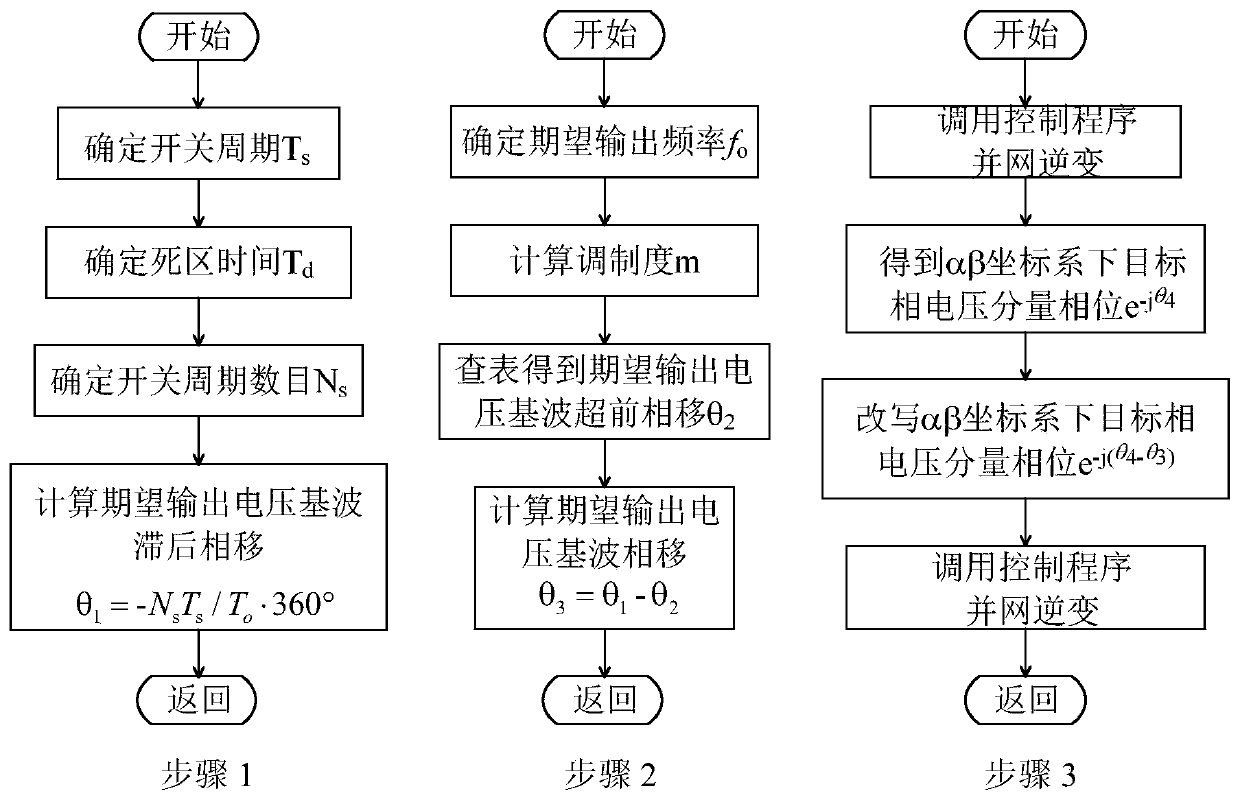

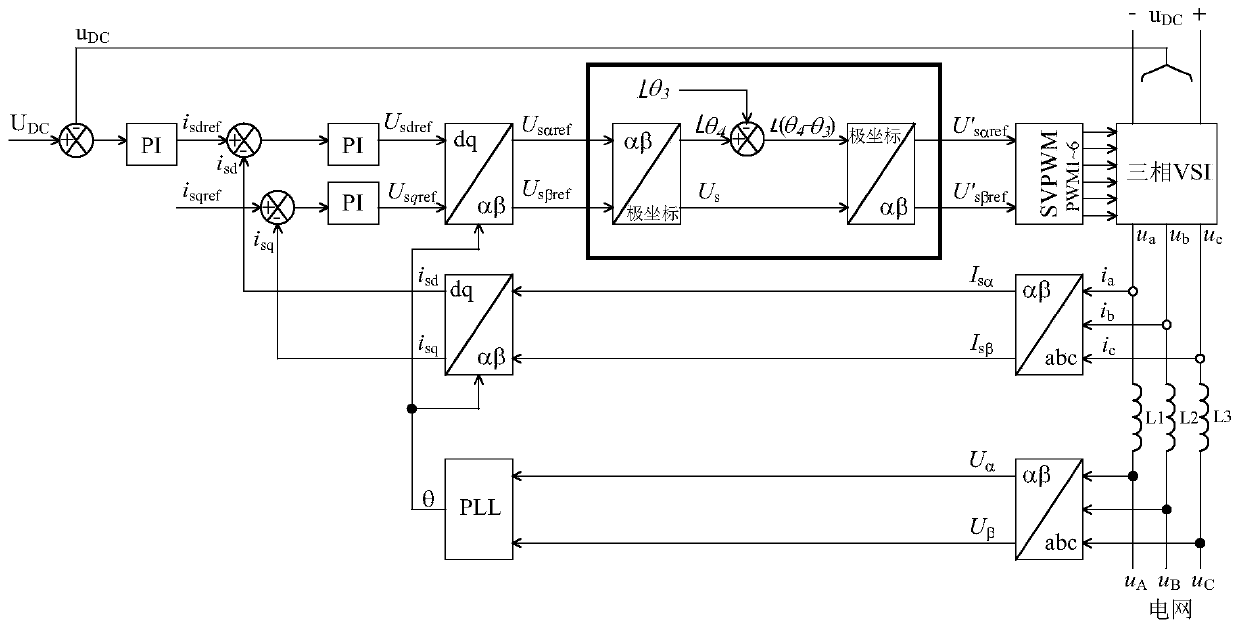

Grid-connected inverter and dead zone phase shift compensation method thereof

ActiveCN111541366ASolve the problem of expected fundamental voltage phase shiftSolve the problem of fundamental wave phase lagAc-dc conversionSingle network parallel feeding arrangementsGrid connected inverterPhase shifted

The invention provides a grid-connected inverter and a dead zone phase shift compensation method thereof. The dead zone phase shift compensation method comprises the steps of calculation of phase shaft cased by lagging by determining a switching period of the grid-connected inverter, determining dead time of the grid-connected inverter, determining the number of delay switching periods required for generating a PWM driving signal of the grid-connected inverter, and calculating the lagging phase shift caused by switching period beat; calculation of phase shift caused by dead zone by determiningthe expected output voltage frequency of the grid-connected inverter, determining the modulation degree of the grid-connected inverter, obtaining expected output voltage fundamental wave leading phase shift caused by a dead zone and calculating an expected output voltage fundamental wave total phase shift; and fundamental wave phase shift compensation by obtaining a target phase voltage componentphase under an alpha beta coordinate system, rewriting a target phase voltage component phase under an alpha-beta coordinate system, and calling an SVPWM or SPWM program in the grid-connected inverter control program to generate a grid-connected inverter driving signal for grid connection. The method is beneficial to accurate phase control of the grid-connected inverter and has the advantages ofbeing simple, clear in logic, capable of improving grid-connected control precision and the like.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com