Laser phased array multi-beam forming system and method

A phased array and multi-beam technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of reducing sub-beam efficiency and scanning accuracy, increasing sub-beam width, etc., to achieve multi-beam forming and deflection, accurate Effect of Amplitude and Phase Control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

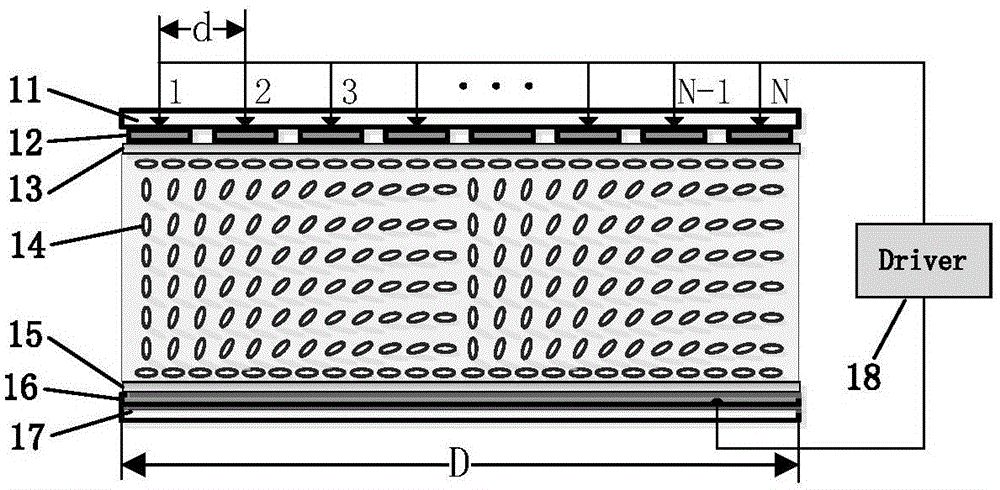

[0032] Such as figure 1Shown is a schematic structural diagram of the liquid crystal optical phased array used in the present invention, the liquid crystal optical phased array includes: an upper glass substrate 11 and a lower glass substrate 17 placed relatively parallel. The upper substrate contains an alignment layer 13 and a transparent and conductive ITO electrode layer. The electrode layer on the upper substrate is used as an array grating electrode 12. The number of grating electrodes is N, and the distance between adjacent electrodes is d. The effective aperture size formed by the grating electrode is D. The lower substrate contains an alignment layer 15 and a transparent and conductive ITO electrode layer, and the electrode layer on the lower substrate serves as a common electrode 16 . A liquid crystal material 14 is filled between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com