Assembly phase control method of crank head connecting block for large-interference crank shear

A technology of phase control and connecting blocks, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of poor phase control, time-consuming and laborious rework, low installation success rate, etc., to achieve simple equipment, convenient operation, phase Control precise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

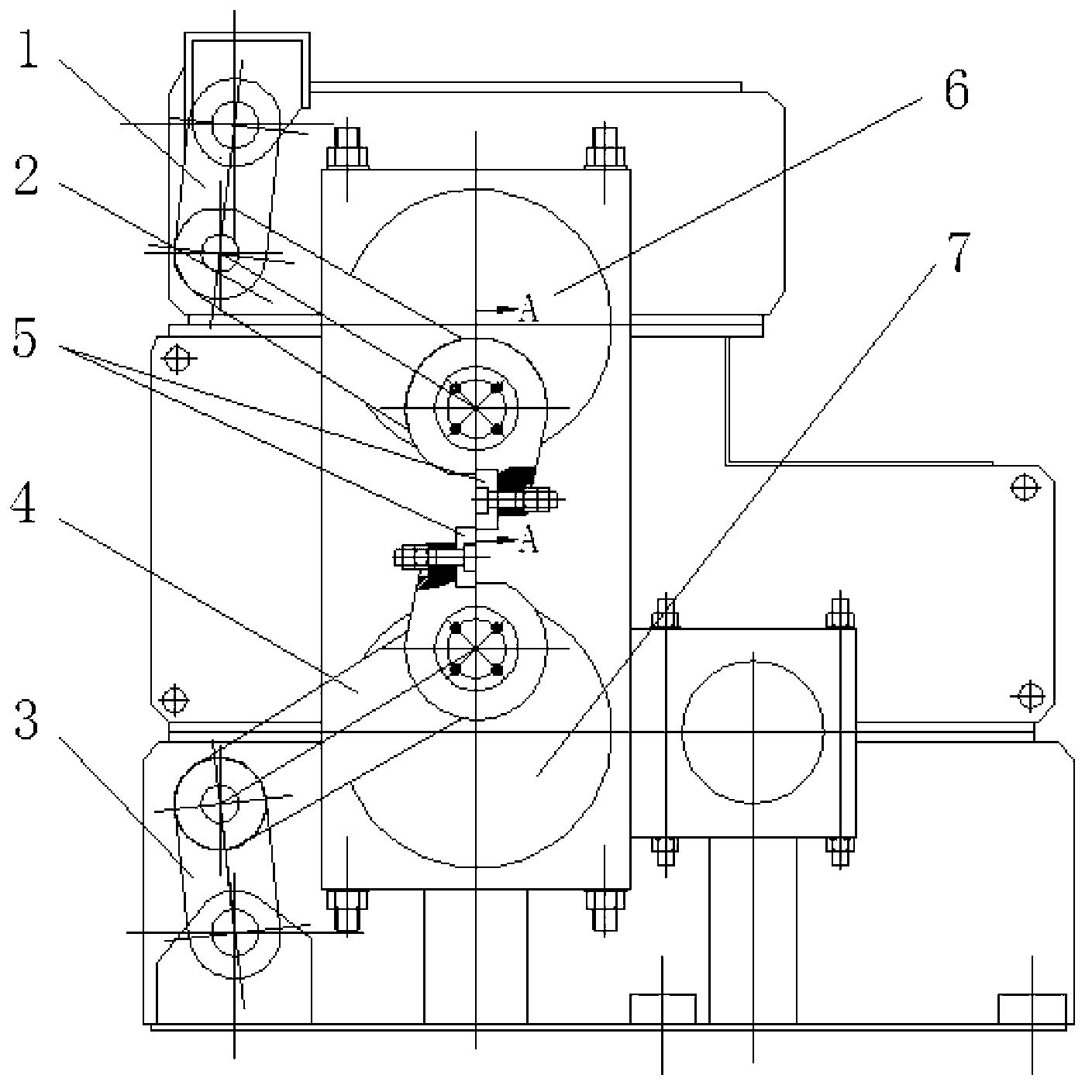

[0023] Such as figure 1 , figure 2 As shown, it is a schematic structural diagram of a crank shear that is often used in existing steel mills, including an upper crank head connecting block 6 and a lower crank head connecting block 7, wherein the upper crank head connecting block 6 is connected with the upper shear blade, and the lower crank head The head connecting block 7 is connected with the lower cutting edge, and the upper cutting edge and the lower cutting edge together form the cutting edge 5; the upper crank head connecting block 6 is sequentially connected with connecting rod two 2 and connecting rod one 1, and the lower crank head connecting block 7 is sequentially It is connected with connecting rod four 4 and connecting rod three 3;

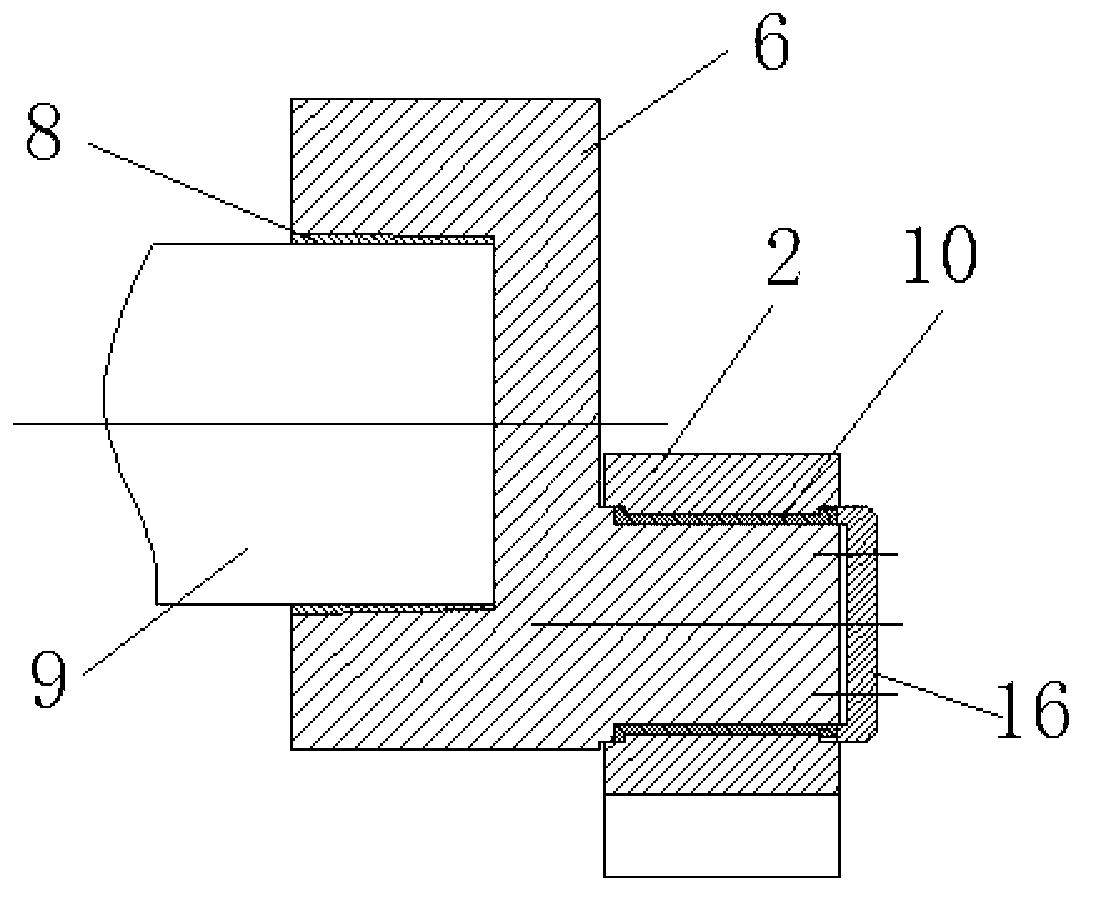

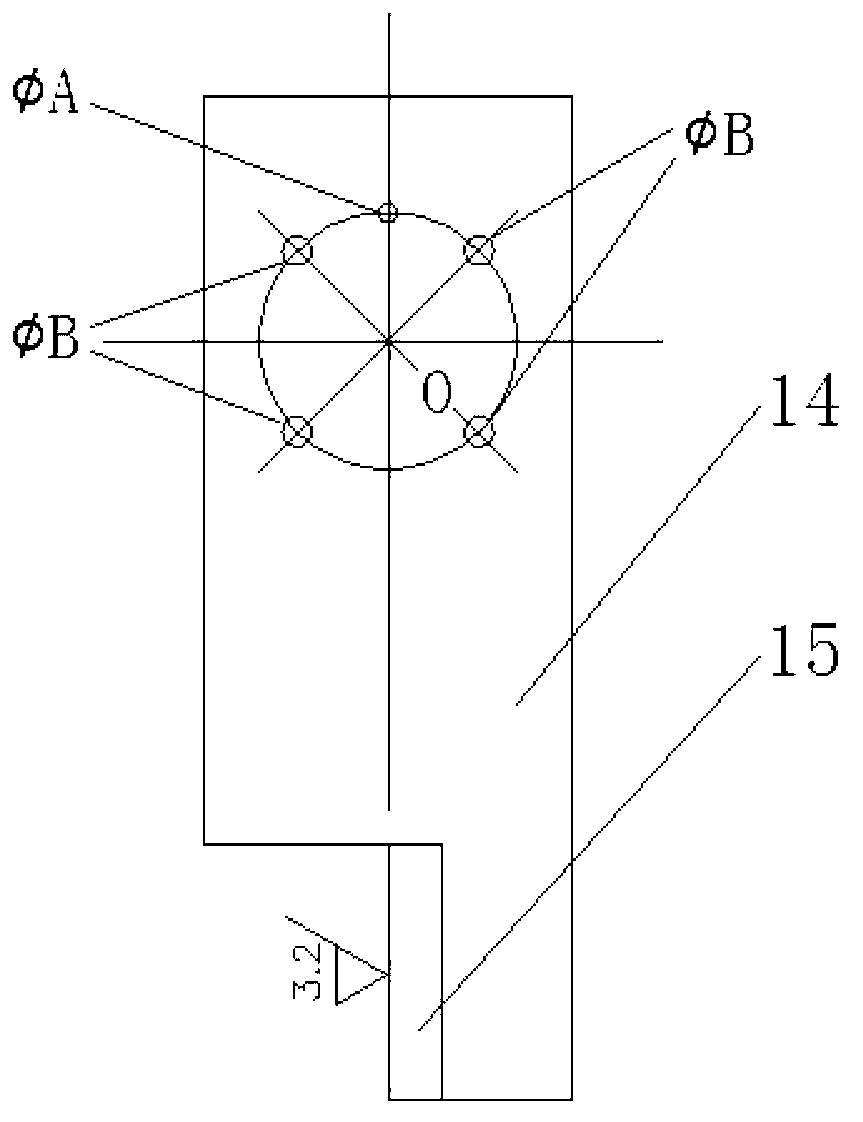

[0024] The outer side of the upper crank head connecting block 6 is connected with the connecting rod 2 through the outer bushing 10, and the inner end surface axis hole of the upper crank head connecting block 6 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com