Automatic dispenser

A dispensing machine, automatic technology, applied in the direction of coating, liquid coating device on the surface, etc., can solve the problem of inability to meet the high-quality requirements of the filter, the quality is difficult to be effectively guaranteed, and the consistency of manual dispensing products is poor, etc. problems, achieve the effect of shortening dispensing time, good consistency and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

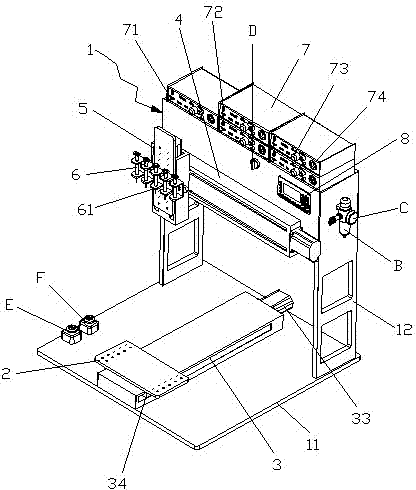

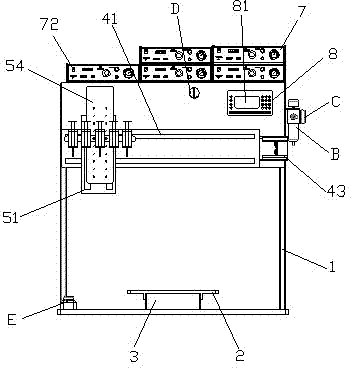

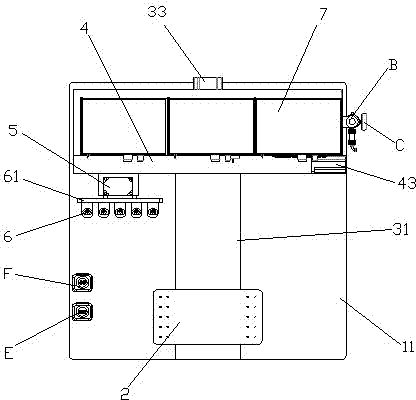

[0028] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0029] Figure 1 to Figure 12 Shown is the structure and working state schematic diagram of the present invention.

[0030] The reference signs are: tooling splint A, air filter B, air pressure master C, main control power switch D, start switch E, emergency stop switch F, dispensing frame 1, base plate 11, gantry frame 12, working Plate 2, Y-axis screw group 3, Y-axis guide plate 31, Y-axis screw 32, Y-axis progressive motor 33, Y-axis slider 34, X-axis screw group 4, X-axis guide plate 41, X-axis progressive motor 43 , Z-axis screw group 5, Z-axis guide plate 51, Z-axis progressive motor 53, Z-axis slide plate 54, dispensing needle head 6, dispensing needle holder 61, dispensing air pressure control box 7, glue outlet connector 71, outlet Glue switch button 72, pressure adjustment knob 73, pressure display gauge 74, glue dispensing automati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com