Vacuum suction machine for garbage disposal

A vacuum suction machine, garbage disposal technology, applied in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc. , to increase the suction force, facilitate further processing and improve the reliability of equipment operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The vacuum suction machine for garbage disposal of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

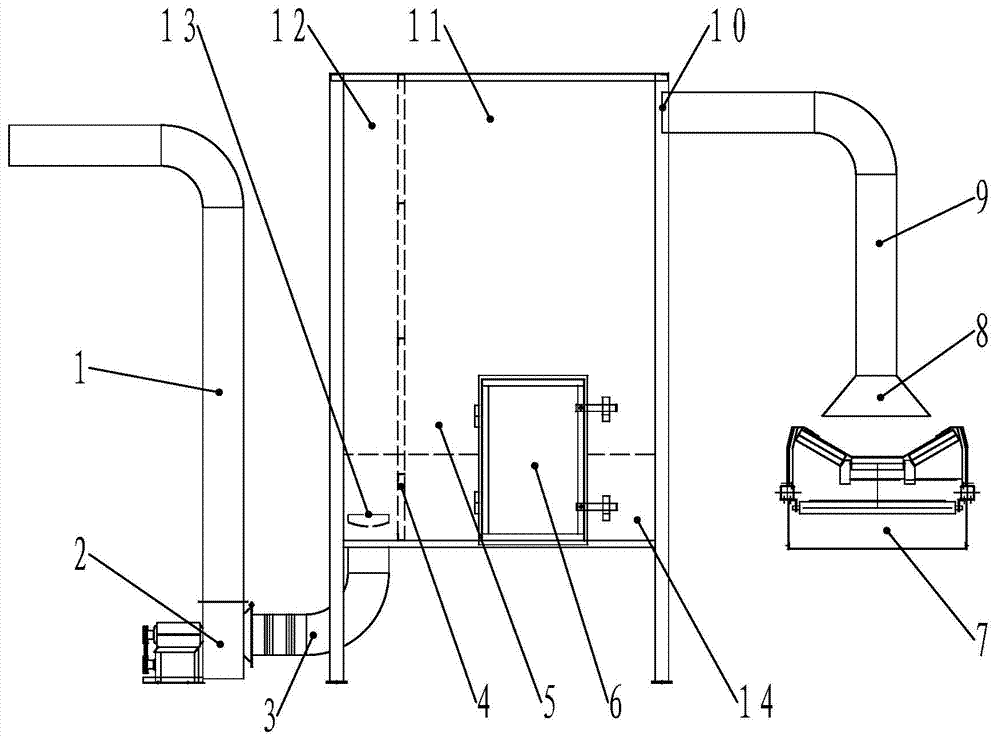

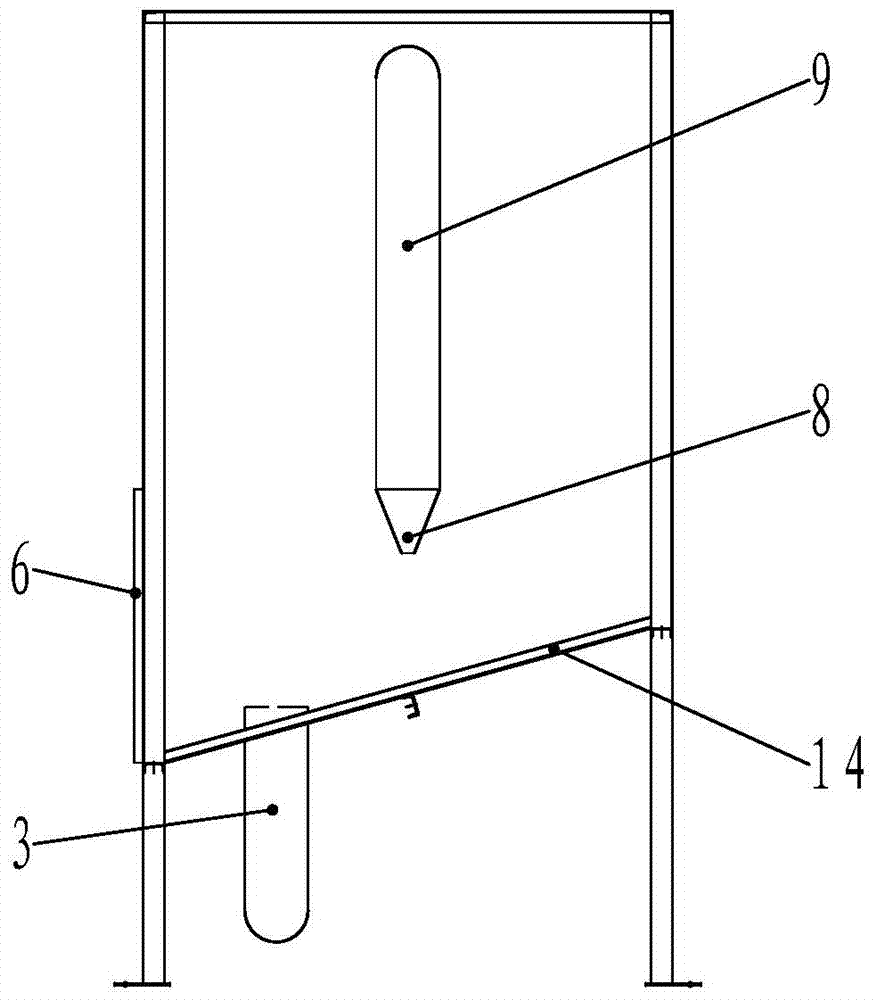

[0017] figure 1 It is a structural schematic diagram of the garbage disposal vacuum suction machine of the present invention, figure 2 yes figure 1 In the figure, the waste disposal vacuum suction machine includes a storage bin 5, the bottom of the storage bin 5 is provided with a bottom plate 14, and for the convenience of discharging, the bottom plate 14 is obliquely arranged at the bottom of the storage bin 5, and the storage There is an upright air-material isolation net 4 inside the bin 5, and the gas-material isolation net 4 divides the storage bin 5 into a suction nozzle area 12 and a suction nozzle area 11, and the suction nozzle area 12 is provided on the bottom plate. mouth 13, a centrifugal fan 2 is arranged next to the storage bin 5, the inlet of the centrifugal fan 2 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com