Split heating type crude oil storage device

An oil storage device and heating technology, which is applied to railway car body parts, transport passenger cars, tank cars, etc., can solve problems such as high maintenance costs, hidden safety hazards, carbon deposition in electric heating tubes, etc., and achieve low operating costs, reduced impact, and high energy efficiency. The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

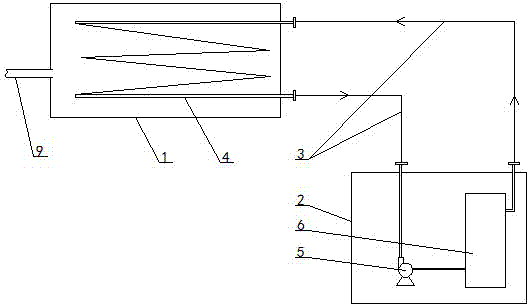

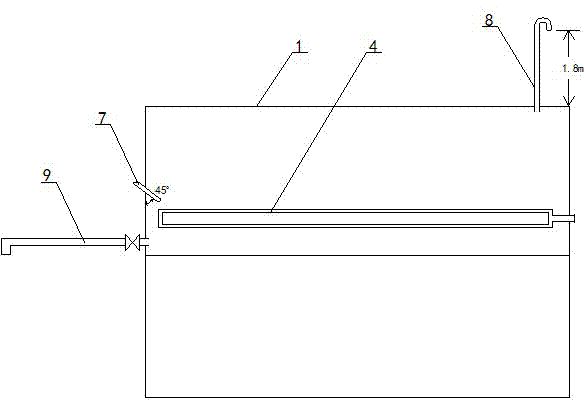

[0018] The separate heating type crude oil storage device of the present invention comprises an elevated oil storage tank 1 , a heating skid 2 and a connecting pipeline 3 .

[0019] The overall structure of the elevated oil storage tank 1 is basically the same as that of the elevated oil storage tank in the prior art. The difference is that a heating coil 4 is fixed inside the elevated oil storage tank 1 . The installation position of heating coil pipe 4 is higher than loading crude oil outlet 9 200 millimeters. The front end of the elevated oil storage tank 1 is equipped with a thermometer 7 . The thermometer 7 is installed at an angle of 45° with the wall plate of the tank body 1 of the oil storage tank, which can be displayed nearby and transmitted to the temperature control cabinet remotely. The rear portion of the top of the elevated oil storage tank 1 is provided with an exhaust pipe 8 for harmful gases such as hydrogen sulfide. The vertical height from the discharge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com