Folding machine and working method thereof

A folding machine and workbench technology, applied in the field of folding machines, can solve the problems of lack of automatic alignment function, low processing efficiency, cumbersome operation, etc., and achieve the effect of realizing folding, improving production efficiency, and avoiding cumbersome operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

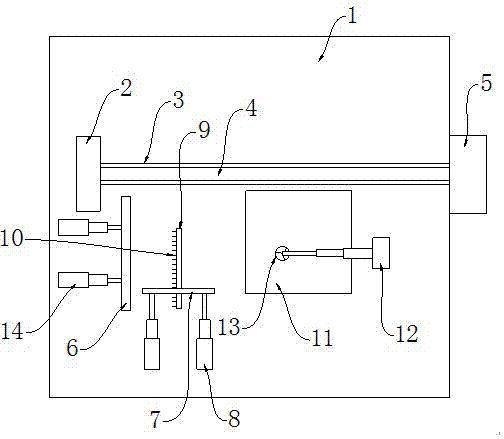

[0019] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings. As a preferred embodiment of the present invention, please refer to figure 1 , a folding machine, including a workbench 1, a groove 3 placed on the workbench 1, and a pressing rod 4 placed on the groove 3 and used for folding, one end of the pressing rod 4 is arranged on the workbench The bracket 2 on the 1 is connected by rotation.

[0020] The workbench 1 is provided with a limit groove 9 perpendicular to the groove 3, and the limit groove 9 is provided with a limit block 7 parallel to the groove 3 and moving along the length direction of the limit groove 9. The limit block 7 A first driving cylinder 8 for advancing the limit block 7 to make the limit block 7 approach or move away from the pressure rod 4 is provided on one side of the cylinder. One side of the workbench 1 placed on the limit groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com