Road roller open type vibration system with automatic frequency adjustment and single and double vibration functions

An automatic frequency modulation and vibration system technology, which is applied in roads, roads, road repairs, etc., can solve problems such as poor operating comfort, affecting compaction quality, and impossibility, and achieve improved stability, flatness, and operating comfort. The effect of consistent frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

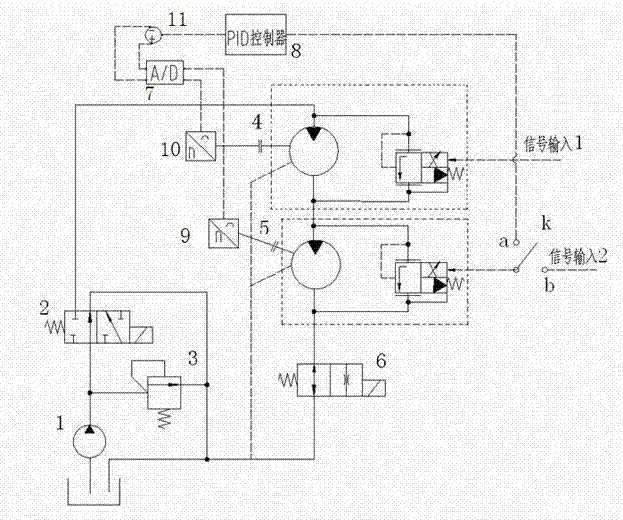

[0019] see figure 1 , The present invention relates to an open vibration system of a road roller with automatic frequency regulation and single and double vibration functions, which includes a hydraulic part and a control part.

[0020] The hydraulic part includes a gear pump 1, a solenoid valve 2, a first motor 4, a second motor 5 and a solenoid valve 6. The first solenoid valve 2 is connected with a safety valve 3. When the first solenoid valve 2 is de-energized, the gear The pressure oil output by the vibration of the pump 1 is directly returned to the oil tank through the first solenoid valve 2, and the system is unloaded; when the first solenoid valve 2 is energized, the high-pressure oil enters the first motor 4 through the first solenoid valve 2, and the first motor 4 The oil output from the second motor 5 enters the second motor 5, and the oil output from the second motor 5 returns to the oil tank through the second electromagnetic valve 6. When the vibration is stoppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com