Method for strengthening box girder prefabricated segment box chamber

A segment and box room technology, applied in bridge reinforcement, bridge, bridge construction, etc., can solve problems such as troublesome implementation, heavy weight, and complexity, and achieve the effect of saving materials, convenient implementation, and computational science.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

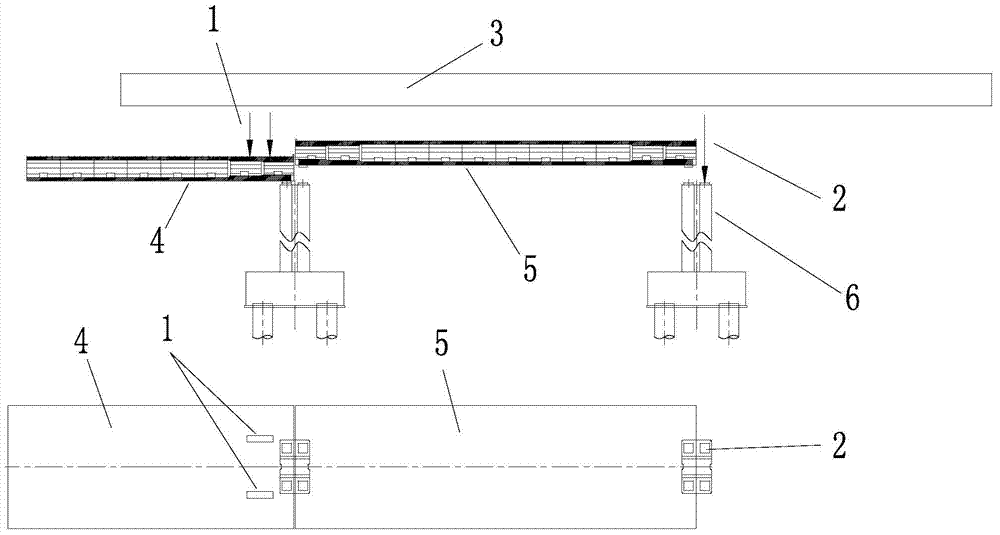

[0030] The embodiment of the present invention is the 2312 mark of the R2 line of urban rail transit in Dongguan City, and the bridge erecting machine 3 is used as the DP50 / 30-A3 uplink segmental assembly bridge erecting machine 3; according to figure 1 , when installing the box girder precast section, the RA outrigger 1 of the bridge erecting machine 3 is supported on the beam end of the installed box girder precast section 4, the RB outrigger 2 is supported on the pier 6, and the box girder precast section 5 to be installed Suspended on the bridge erecting machine 3;

[0031] Step 1: After determining the relevant basic data, check and calculate the local pressure of the RB outrigger 2 placed at the pier 6 supporting pad stone:

[0032] The size of the supporting pad is 700mm*700mm; the bottom area of the 3 legs of the bridge erecting machine is 490mm*490mm. During the static load test, the reaction force of RB outrigger 2 is 2710KN, and the important coefficient of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com