Assembly type prestress honeycombed web composite beam

A prestressed and composite beam technology, applied in joists, girders, trusses, etc., can solve the problems of the need to improve the shear bearing capacity, affect the mechanical performance of components, and the effect is not very ideal, and achieve excellent out-of-plane stiffness, The effect of improving bearing capacity and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing and example.

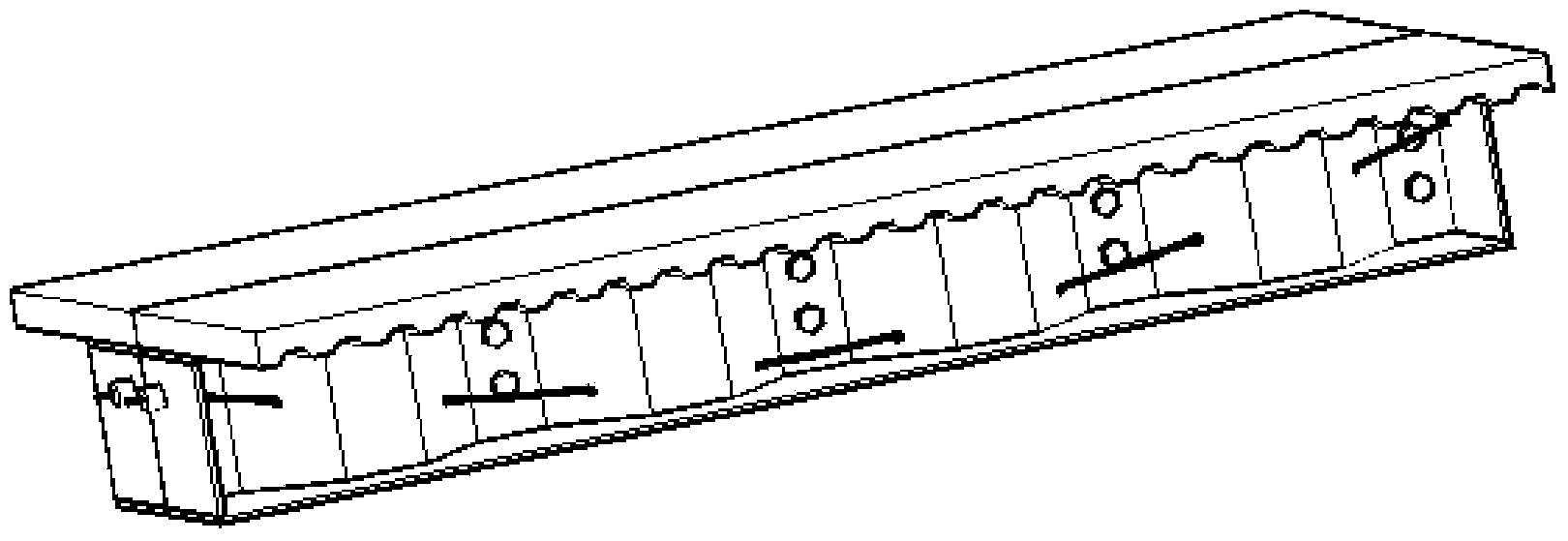

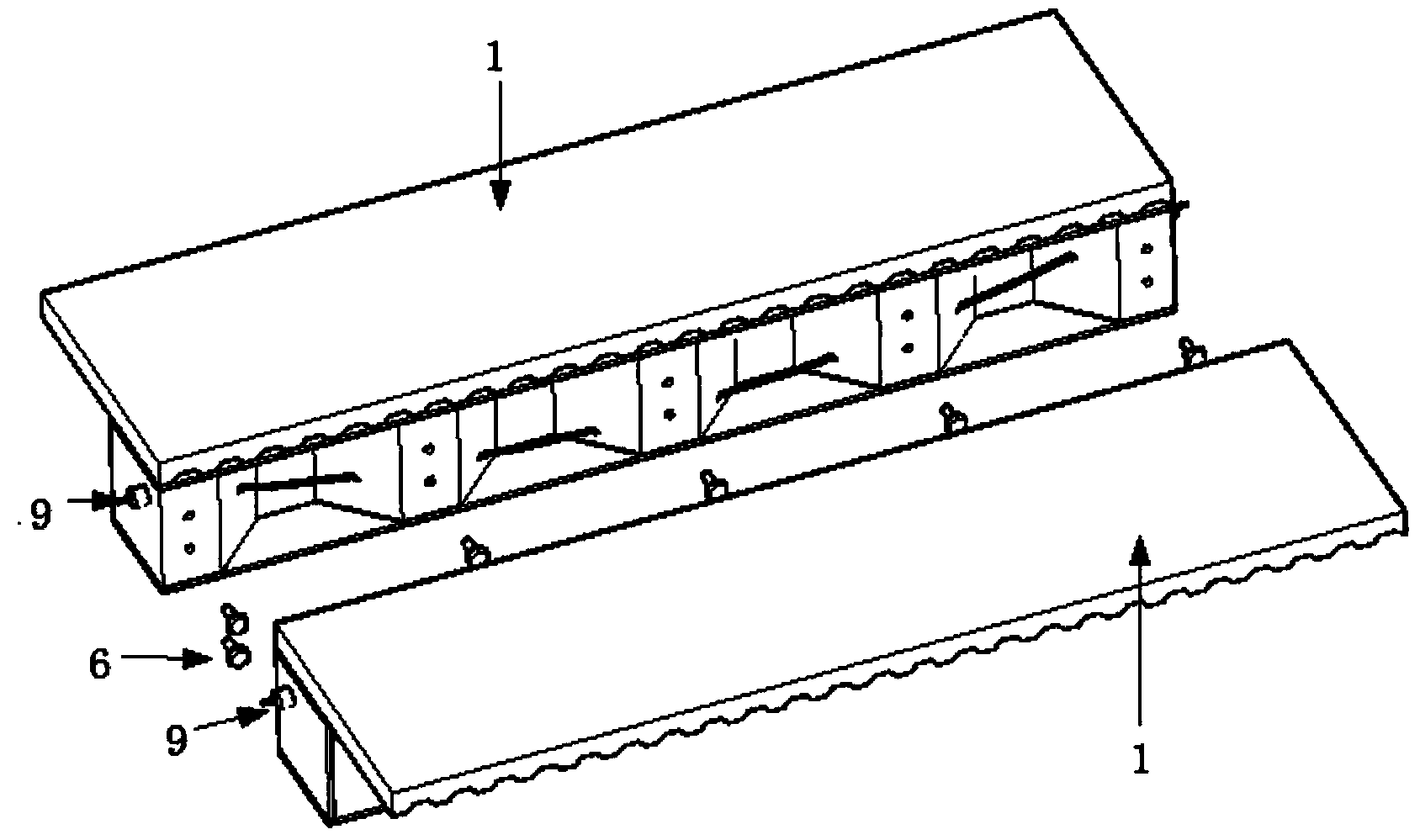

[0031] Such as figure 1 Shown is the structural schematic diagram of the assembled prestressed honeycomb web composite beam, figure 2 It is an exploded view of the structural unit of the assembled prestressed honeycomb web composite beam. The assembled prestressed honeycomb web composite beam proposed by the present invention is assembled by two prestressed corrugated web channel steel composite beams 1 through bolts 6. As a result, the webs of two prestressed corrugated web channel steel composite beams 1 are butted, and the webs are assembled and connected at the bolt holes 5 by using bolts 6 .

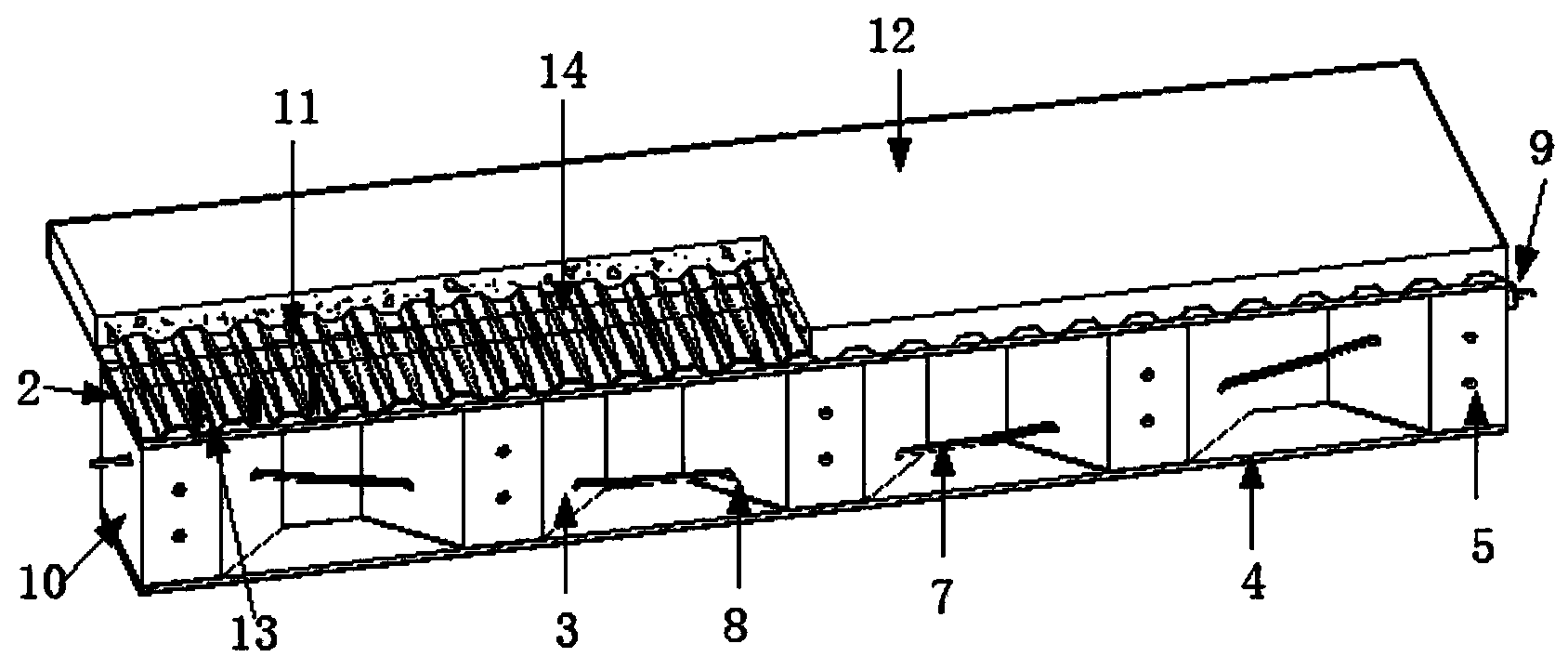

[0032] Such as image 3 The schematic diagram of the trapezoidal cross-section web of the assembled prestressed honeycomb web composite beam is shown, Figure 4 Schematic diagram of the prestressed honeycomb web steel beam, Figure 5 is the element exploded view ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com