Pre-supporting mechanism and tunneling machine

A technology of advanced support and roadheader, which is applied in the direction of mine roof support, mining equipment, earthwork drilling and mining, etc. It can solve the problems affecting the work of roadheader and the small empty head distance of the advance support mechanism, so as to reduce the working intensity and protect the safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

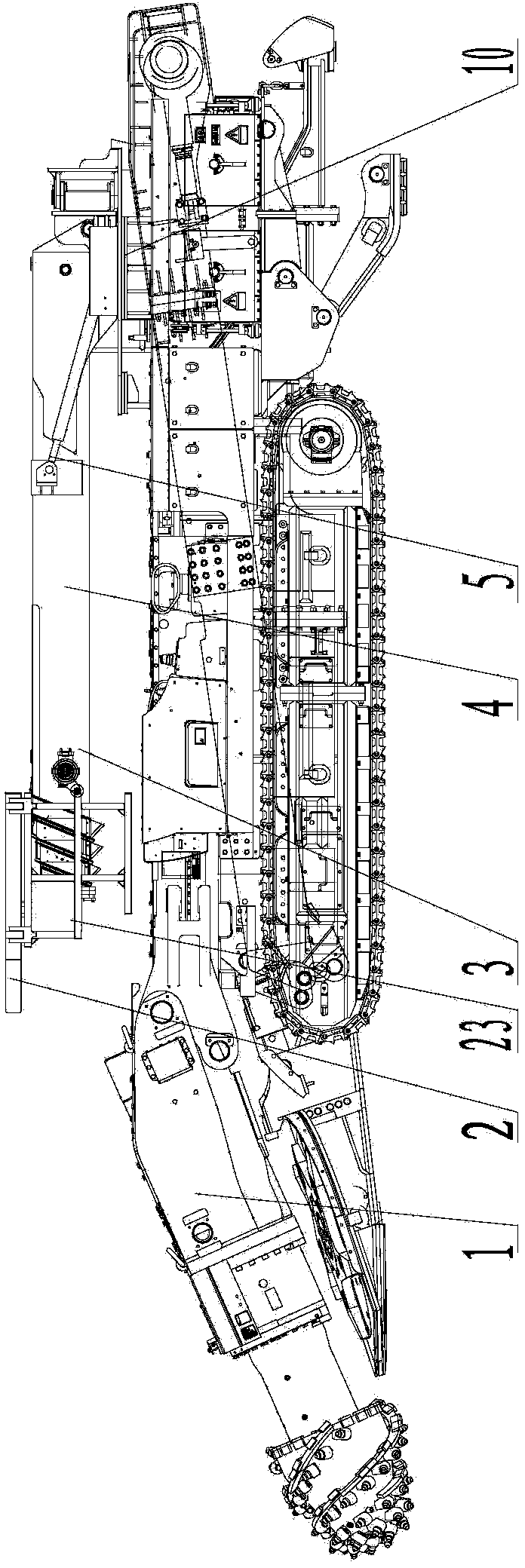

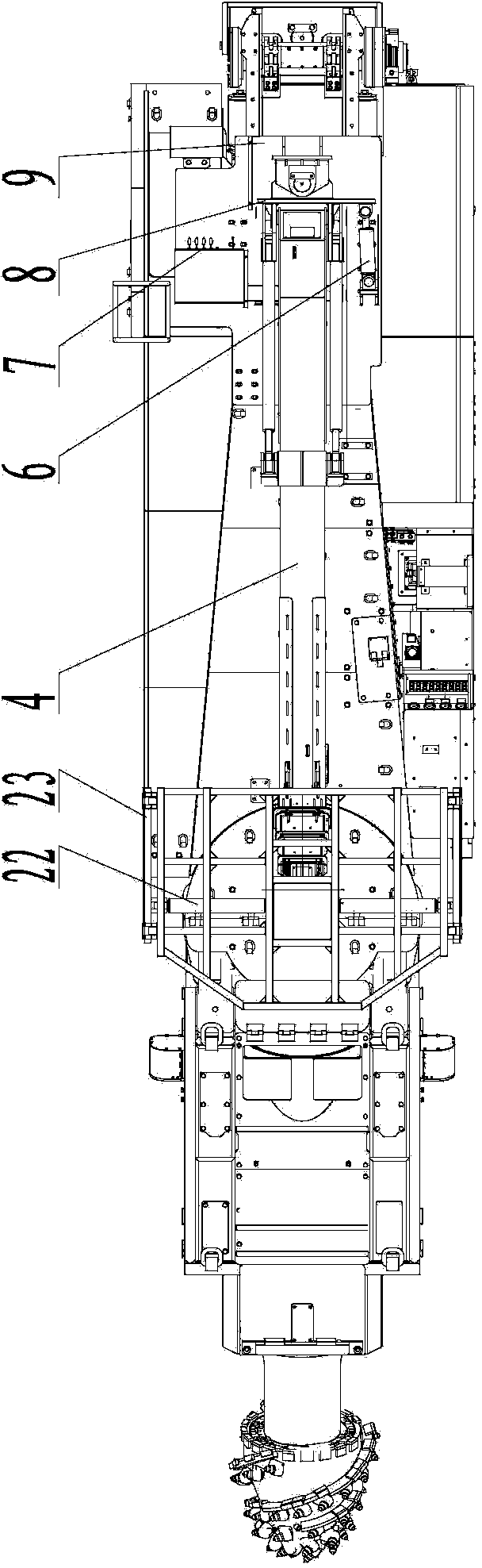

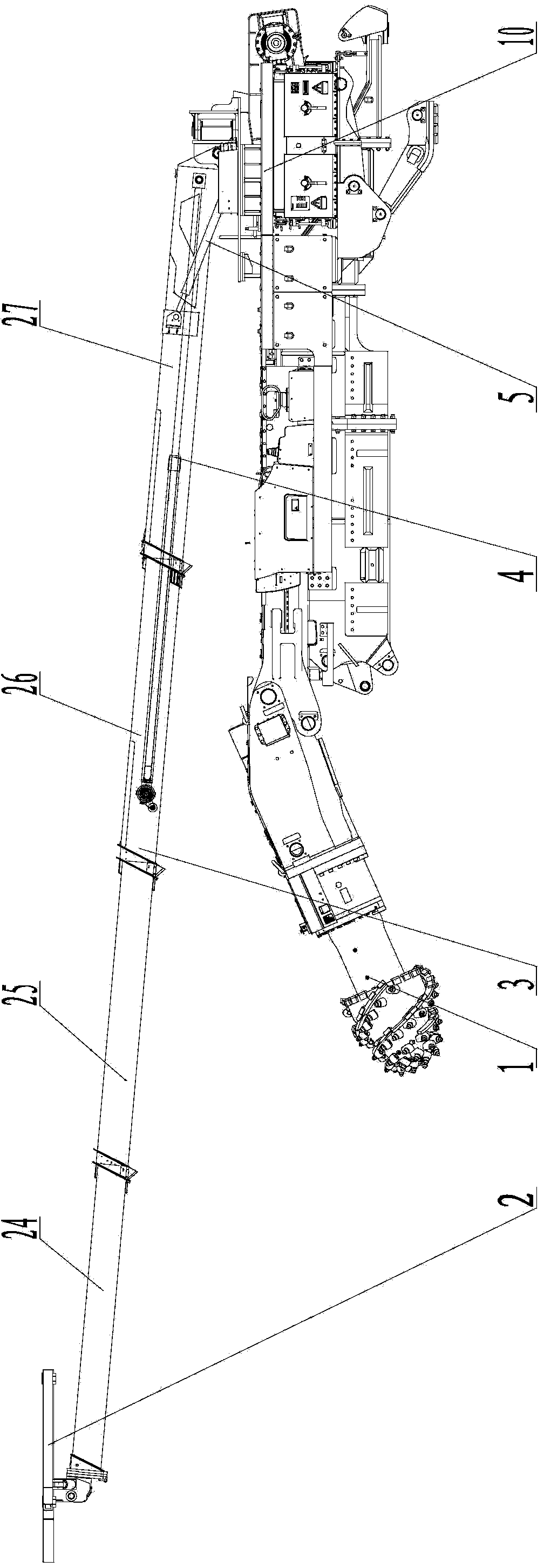

[0052] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be pointed out that the description and sequence of specific structures in this section are only descriptions of specific embodiments, and should not be considered as limiting the protection scope of the present invention.

[0053] In the embodiment of the present invention, by changing the original advance support mechanism in the roadway, the previous manual support or the support structure provided at the cutting part of the roadheader is changed to be installed on the back support of the roadheader, and on the back support of the roadheader. A mounting seat is provided, and a telescopic main arm is installed on the mounting seat. The telescopic main arm can be raised and lowered and rotated through the lifting c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com