Car lamp structure preventing water vapor condensation of car lamp

A technology for car lights and water vapor, which is used in gas/waterproof devices, motor vehicles, road vehicles, etc., can solve the problems of low cost, cannot completely eliminate water vapor condensation, and has no long-term effectiveness, and can solve the problem of heat resistance and prevent water vapor. Condensation phenomenon, the effect of accelerating energy transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

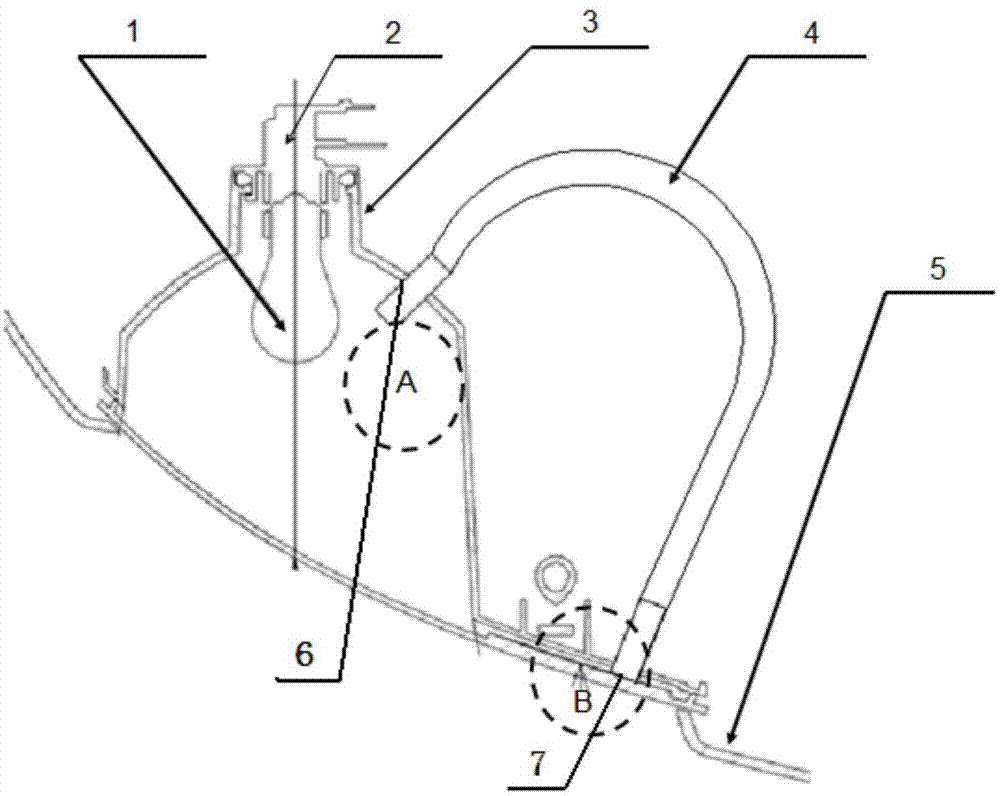

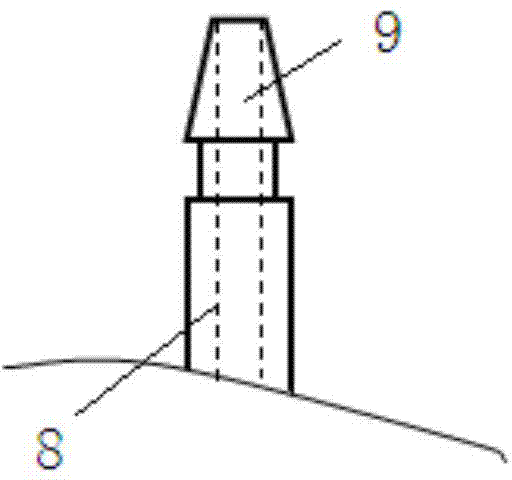

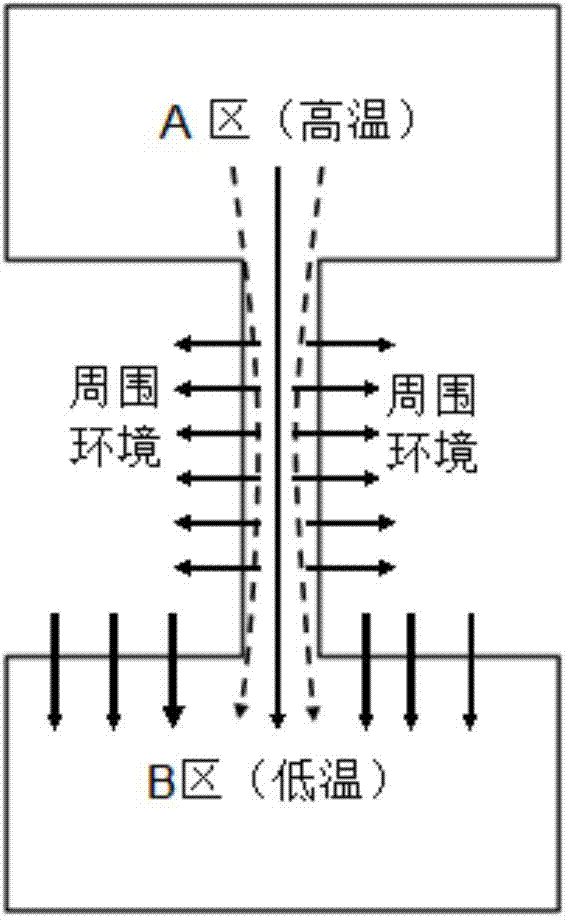

[0022] Such as figure 1 The car lamp structure shown to prevent the condensation of car lights includes a lamp housing 3, a lampshade 5 matched with the lamp housing 3, a light source holder 2 arranged on the lamp housing 3, and a light source 1 fixedly installed on the light source holder 2. There is a first interface 6 on the lamp housing 3 in the light source area, and a second interface 7 is opened on the lamp housing 3 away from the light source area. The first interface 6 communicates with the second interface 7 through the ventilation elbow 4, and the ventilation elbow 4 is suspended in the external surrounding environment of the lamp housing 3, and the ventilation elbow 4 is distributed in the external surrounding environment of the lamp housing 3. Since the ambient temperature is relatively low, when the light source is lit, the energy transfer of the lamp body can be accelerated, so it can It is a good solution to the heat resistance problem of car lights. In this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com