A new and old filter screen replacement method for a no-cleaning air filter device

The technology of an air filter device and replacement method, which is applied to air filter devices, replacement of old filter screens, no-clean air filter devices and new fields thereof, can solve the problems of inconvenient disassembly and cleaning of filter screens, blockage of harmful particles, and inability to introduce fresh air, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

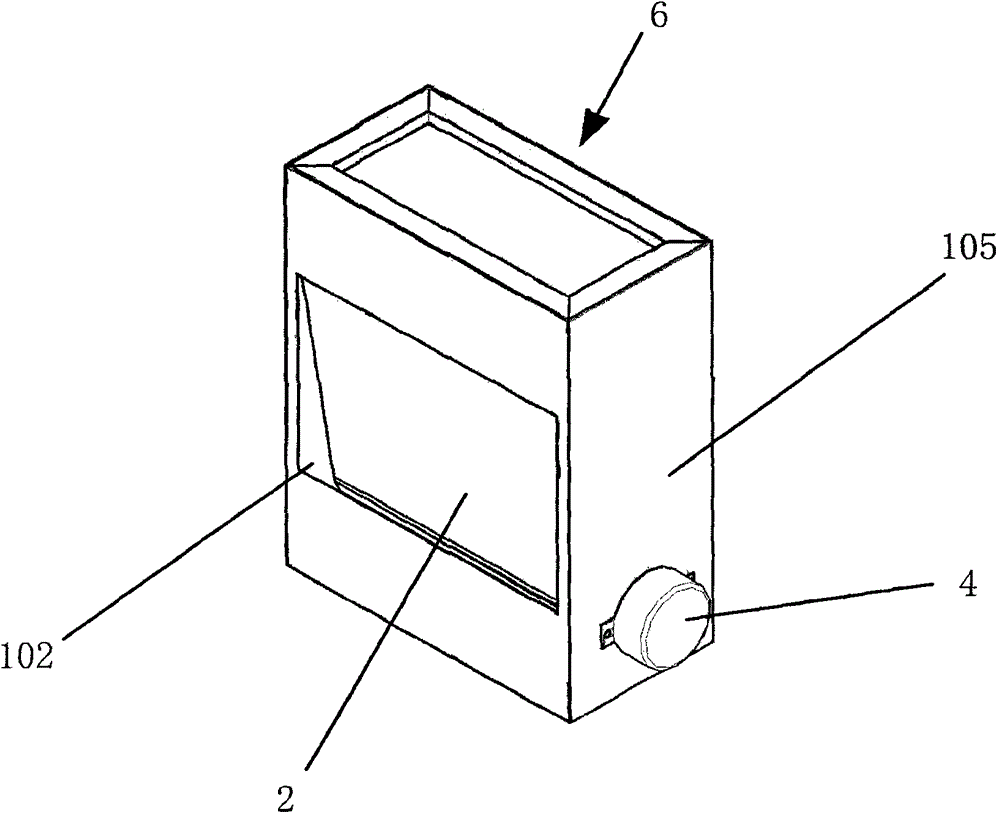

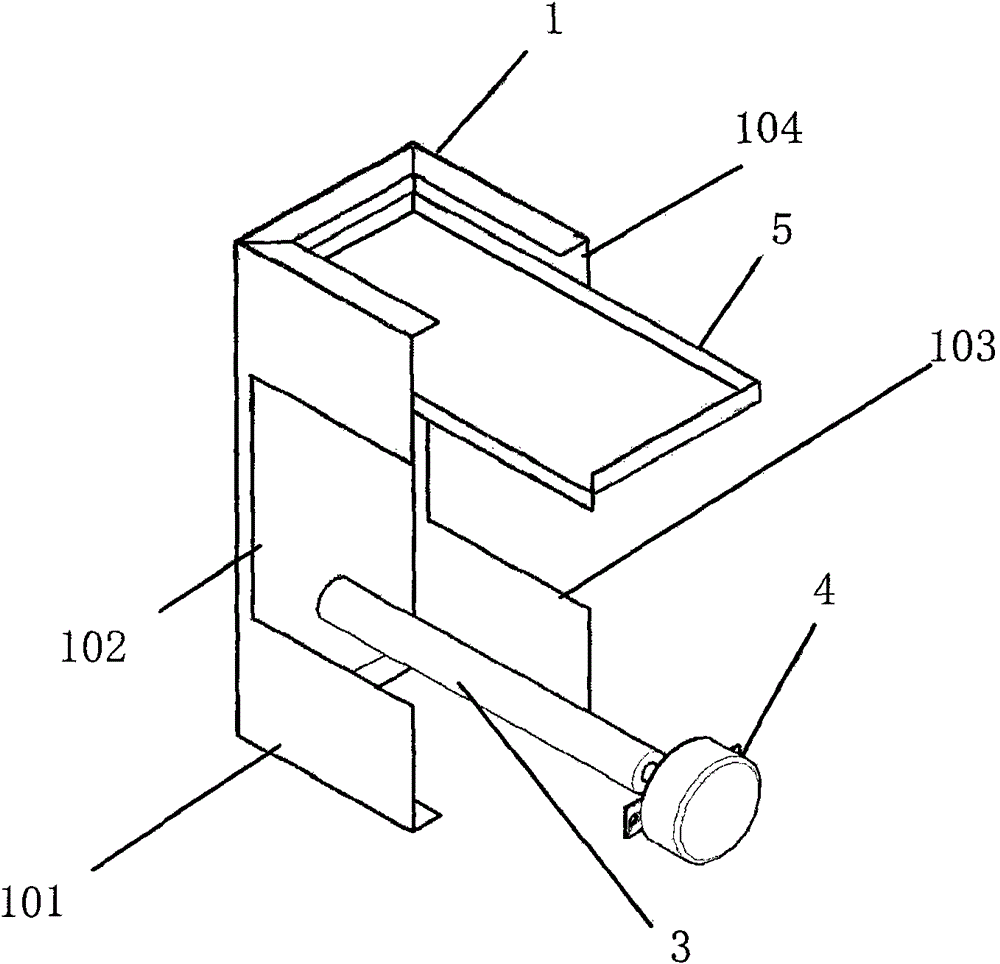

[0127] like Figure 1 to Figure 5 Shown, the structure of a kind of no-cleaning air filter device 6 is:

[0128] It includes a box body 1 and a filter screen 2. The box body 1 is in the shape of a cuboid as a whole. The filter screen 2 is an activated carbon fiber cloth filter screen. 7 used together;

[0129] It is an air treatment device for a full-heat fresh air ventilator, the model of the activated carbon fiber cloth is KJC10-1100; it also includes a rotating shaft 3, a motor 4 and a tray 5;

[0130] The box body 1 includes a lower front and rear baffle plate 101, a middle front air outlet 102, a middle rear air outlet 103, an upper front and rear groove plate 104, and a side plate 105; The motor 4 is arranged outside the side plate 105 on one side, and the motor 4 is fixedly connected to the left end of the rotating shaft 3; the tray 5 is arranged in the lower part of the front and rear groove plates 104;

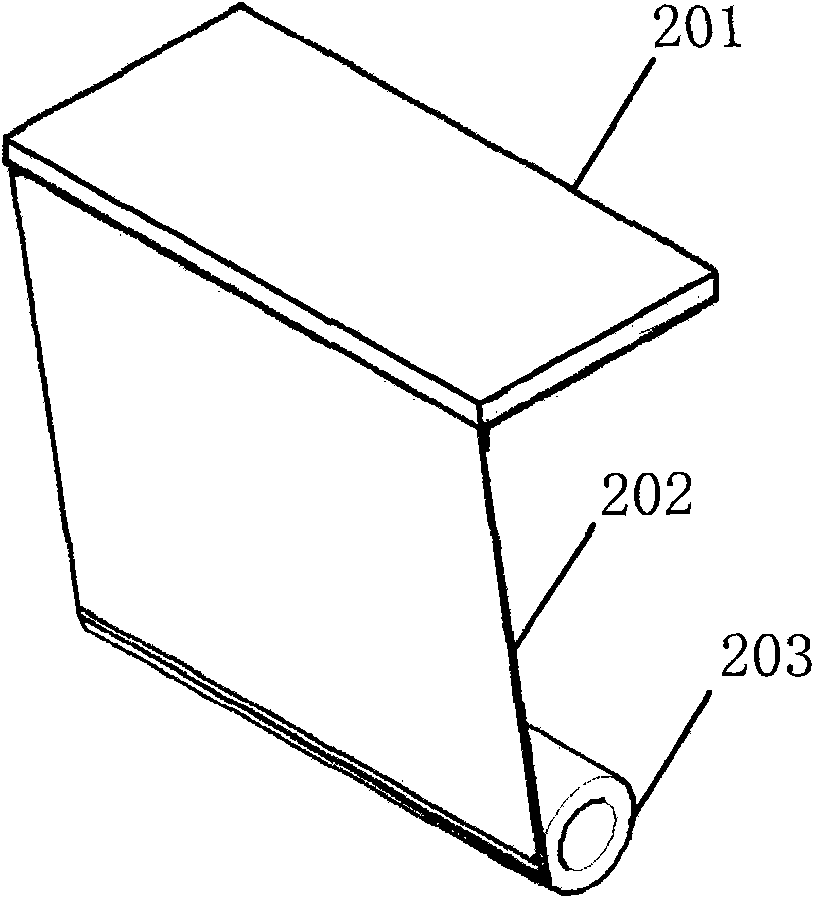

[0131] The filter screen 2 comprises an upper filter screen s...

Embodiment 2

[0147] like Figure 1 to Figure 5 As shown, the main structure of a no-cleaning air filter device 6 is the same as in Embodiment 1, and is used in conjunction with a photoelectric controller (not shown in the figure) arranged on the no-cleaning full-heat fresh air ventilator 7. It includes a transmitter and a The receiving end is an active photoelectric detection system electronic switch using pulse modulation, which converts the change of light intensity between the transmitting end and the receiving end into a change in current to achieve the purpose of detection; the transmitting end and the receiving end The end is set at the front and rear of the working layer of the filter in the middle, and the limit stroke hole is made on the filter 2 first. When the filter 2 is polluted after a certain set time, the motor 4 is started. When the light passes through the first When the limit travel hole is punched, the photoelectric control instrument controls the motor 4 to stop, and t...

Embodiment 3

[0150] like Figure 1 to Figure 5 As shown, the structure of a no-cleaning air filter device 6 is completely the same as that of Embodiment 1. The replacement operation method of new and old filter screen 2 is to replace new and old filter screen 2 with manually starting and shutting down the motor, and first manually starts motor 4 to make new filter screen 2 work from the upper filter screen stack 201 to the middle filter screen The layer 202 rotates, and the old filter screen 2 rotates from the middle filter screen working layer 202 to the bottom dirty screen reel 203 until the replacement of the new and old filter screen 2 is completed, and then the motor is turned off manually; the working environment is relatively bad, and the filter screen is often blocked When the time comes, you can use the above-mentioned manual operation method, so that the contaminated filter screen can be replaced at any time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com